Electrifying plastics

A family-run business in Italy is moulding the future of plastic injection technology.

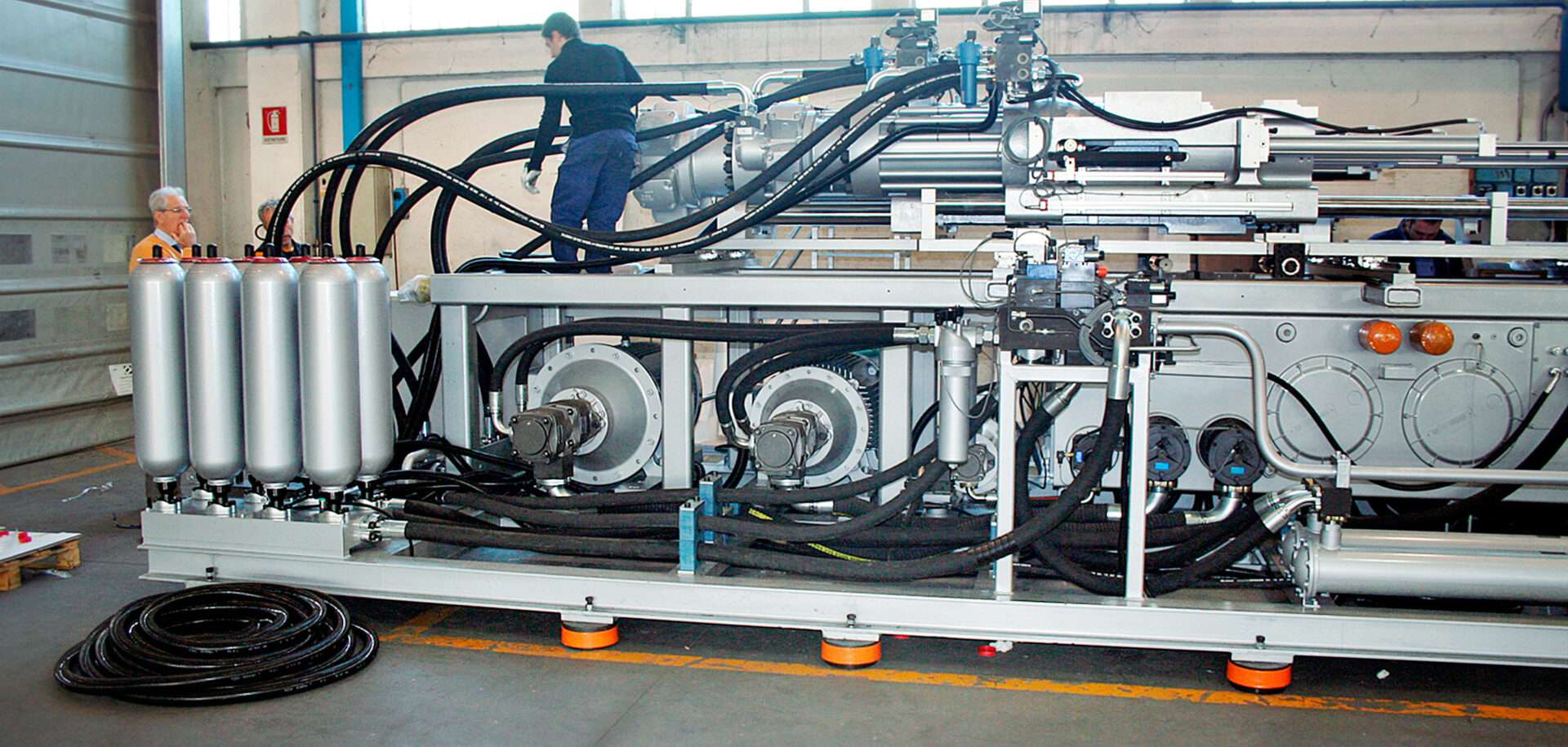

“Plastics” became famous as a one-word description of the future in the 1967 film The Graduate. That same year, three Italians in Brescia, a city near Milan, founded a company based on their hopes for the future of plastics. Egidio Bugatti, his brother Domenico and their brother-in-law Giuseppe Moreschi called their company BMB (after the initials of their surnames) and began by producing machinery for plastic moulding. Egidio Bugatti already had more than a decade’s worth of experience in plastic injection moulding machines and in toggle geometry design. He and his partners were convinced that “plastics” was a growing industry and that they would grow with it by developing machines that were more efficient, more precise and more reliable than those of their competitors. “We had to be better,” Bugatti recalls, because the competition was fierce. Based on this premise, the fledgling enterprise was able to secure orders from such high-profile corporations as Olivetti, Bic and Coster – blue-ribbon clients whose products demanded speed, precision and built-in quality control. “They contributed to our growth and helped us position ourselves in the high end of our market,” Bugatti says. BMB grew steadily throughout the 1970s by emphasizing several core principles: product quality, machine precision and honesty in dealing with customers. The company applied for its first patent in 1980, becoming the first moulding machinery manufacturer to integrate electronics into its products. Also in 1980, the company outgrew its original location and moved to its current headquarters in the main industrial area outside the Brescia city centre. The facility grew over time and today consists of three contiguous buildings housing administration, technical offices and three production areas (for machines weighing up to 400 tonnes, for machines in the 450–3,500-tonne range, and for machines of more than 3,500 tonnes). The facility, covering 30,000 square metres, is thoroughly modern and spotlessly maintained. Throughout the 1980s, BMB continued to grow, producing traditional injection moulding machines with high performance and consistent reliability. Although the company sold some machines abroad, its market and reputation were largely limited to Italy. All this began to change in the 1990s. Bugatti’s son Marco, a graduate of Milan’s Polytechnic University, joined the company in 1994 after a period of working for BMB in the UK. He pushed for a revision of the company’s commercial structure and encouraged greater emphasis on foreign markets. Today, 85 percent of BMB’s sales are outside Italy, with strong demand in Latin America and a recent focus on North America. More dramatic is the change in product line-up. As recently as eight years ago, all of BMB’s injection moulding machines were powered by hydraulics. Today, only 20 percent are hydraulic. All-electric machines, first developed by BMB in 2005, represent 35–40 percent of the annual output, and hybrid machines, introduced in 2007, make up 40–45 percent of the annual output. Electric-powered moulding machines have been operating in Japan since 1983. But despite their advantages – reduced energy consumption, greater precision, environmental friendliness, relatively compact size and lower lifetime costs – the machines have a higher initial price tag, so customers outside Japan were initially loath to try them out. That changed when energy costs skyrocketed. An electric machine may cost 30 to 40 percent more at the outset, but it saves 40 percent in total life-cycle costs in addition to other major advantages. BMB built its first electric prototype in 2002 and turned to hybrids when its clients demanded larger machines capable of greater speeds for thin-walled, difficult-to-handle products that electric machines were not yet capable of handling. For example, BMB’s eKW70PI/7000 hybrid machine, introduced in 2008, produces yogurt pots on a 16+16 cavity mould. It uses electric drive technology for all functions except the actual injection of the plastic, which is powered by a hydraulic accumulator system to achieve the necessary filling speeds. Both Egidio and Marco Bugatti are convinced that in the future their industry will be all electric. “There is plenty of room for growth in the plastics moulding sector,” says Egidio Bugatti, “and we intend to remain at the forefront of its development.” When BMB began focusing on electric equipment in 2004, it sought out SKF. “We knew SKF had expertise in roller screws and in electric moulding machines,” explains BMB President Egidio Bugatti, “so we wanted it as a partner in developing an electric machine capable of handling a four-second cycle at high speeds.” SKF’s range of extra-high load capacity planetary roller screws was specifically created to meet these tough requirements. One example can be found in BMB’s new hybrid 1,700-tonne plastic injection moulding machine. Its toggle movement is the largest ever made with electromechanical technology, requiring high pressures that carry a high risk of misalignment. SKF’s planetary roller screws are specifically designed to avoid such problems and the resultant downtime. In addition, notes SKF Mechatronic Business Manager Giuseppe Saroglia, “they drastically reduce the quantity of hydraulic oil needed and its consequent cooling demand.” Electromechanical giant