Spherical roller bearings: The bearing for all seasons

In 1919 SKF launched a product that was to transform the world of bearings and their applications in countless industries. Over the past 100 years, the spherical roller bearing has continued to evolve, thanks to continual innovation that has pushed the boundaries of its performance. For the foreseeable future the spherical roller bearing will continue to be one of the most versatile bearings for countless engineering tasks.

How the spherical roller bearing was invented

SKF engineer Arvid Palmgren is credited with the development of the spherical roller bearing. He joined SKF in 1917, taking a position in the company’s marketing department to work on technical information. Realizing that he lacked much of the background he needed to provide technical details, he set about working on bearing theory and started carrying out laboratory experiments.

In 1918 SKF started to develop a bearing that could accommodate the loads for wheel set bearing arrangements in railway applications, and Palmgren was asked to study rolling bearings in depth. SKF’s founder, Sven Wingquist, was keen to find a solution as quickly as possible and put all of the company’s resources to the task. Wingquist hoped that the work would take a few weeks, but no theories existed on which they could base calculations for bearing development, so Palmgren carried out tests with various combinations of bearing elements. It took almost six months to achieve a new bearing design. At the heart of his work was his conviction that SKF should create a product that was not only a good solution but that would offer economic value to customers. In June 1919 Palmgren presented a double-row, self-aligning roller bearing that ultimately became one of the company’s greatest technical and commercial successes. He himself became an important person in the engineering world, carrying out research into bearing properties relative to bearing load-carrying capacity and life.

Basic design of the spherical roller bearing

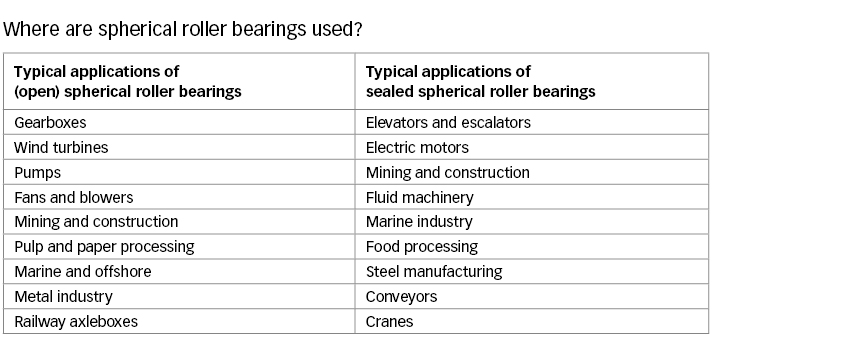

Spherical roller bearings have two rows of symmetrical rollers, a common sphered outer ring raceway and two sphered inner ring raceways inclined at an angle to the bearing axis. The centre point of the sphere in the outer ring raceway is at the bearing axis.

The evolution of the spherical roller bearing has been supported by other product developments and improvements in material quality. These include higher steel grades and the introduction of sealed bearing solutions and better lubrication. Standard spherical roller bearings are manufactured in a wide range of sizes, with bore diameters ranging from 20 millimetres to 1,800 millimetres.

Milestones

In 1951 SKF launched the C design spherical roller bearing, incorporating a floating guide ring and pressed steel cages. The previous bearing design for the smaller bearing sizes had an inner ring with a central guide flange to guide the rollers. The flange had proved to be problematic for applications with combined loads, resulting in high friction and inadequate reliability. The floating guide ring enabled the rollers to position themselves axially without inducing additional internal forces and friction.

This was followed in 1979 by the CC design, which had self-guiding rollers. For the first time SKF was able to optimize the interrelationship between the rollers and raceways using computer-aided analysis. Consequently, there was greater freedom for the rollers to find their own equilibrium position between the raceways. This new design offered lower bearing friction, particularly when accommodating combined loads.

In 1989 SKF responded to industry needs for increased load-carrying capacity for higher-performance machinery by introducing the E design. This involved a radical redesign of the CC design to feature lightweight, high-tech and highly accurate pressed steel cages. These cages provided space for more, considerably larger rollers while still offering the self-aligning feature that promotes low friction. Six years later a range of standard sealed spherical roller bearings was launched.

The game-changing SKF Explorer bearing

The launch of SKF Explorer in 1999 created a new performance class for spherical roller bearings that enabled the power density to be raised significantly. Such was the impact of these bearings that their performance could no longer be predicted by standard bearing life calculations. SKF Explorer was the result of a number of developments, including increasingly sophisticated computer calculation programs to optimize every bearing element, improvements in manufacturing processes and better bearing steels and heat treatments. In operation, customers could benefit from higher load-carrying capacity, much longer service life and increased reliability as well as the ability to increase shaft speeds, reduce power consumption, improve running accuracy and achieve lower noise and vibration levels and a longer lubricant life.

In addition to the bearing design, SKF has emphasized the importance of using the most appropriate seals for tough environments. Consequently, SKF offers sealed spherical roller bearings, which are factory-lubricated with a specially formulated grease. Contact seals can reduce or eliminate relubrication requirements and reduce maintenance costs. Mounting and assembly are easier with sealed solutions. In some applications, moving to a sealed design can increase bearing life rating by up to four times.

Size does matter

At 168 metres tall, the Las Vegas High Roller was the largest observation wheel in the world when it was completed in 2015. The wheel, which carries 28 cabins and up to 40 people in each cabin, rotates on two custom-designed spherical roller bearings. The bearings have a bore diameter of 1,600 millimetres and an outside diameter of 2,300 millimetres and weigh 8.8 tonnes each. Each of the spherical roller bearings has 30 rolling elements per row.

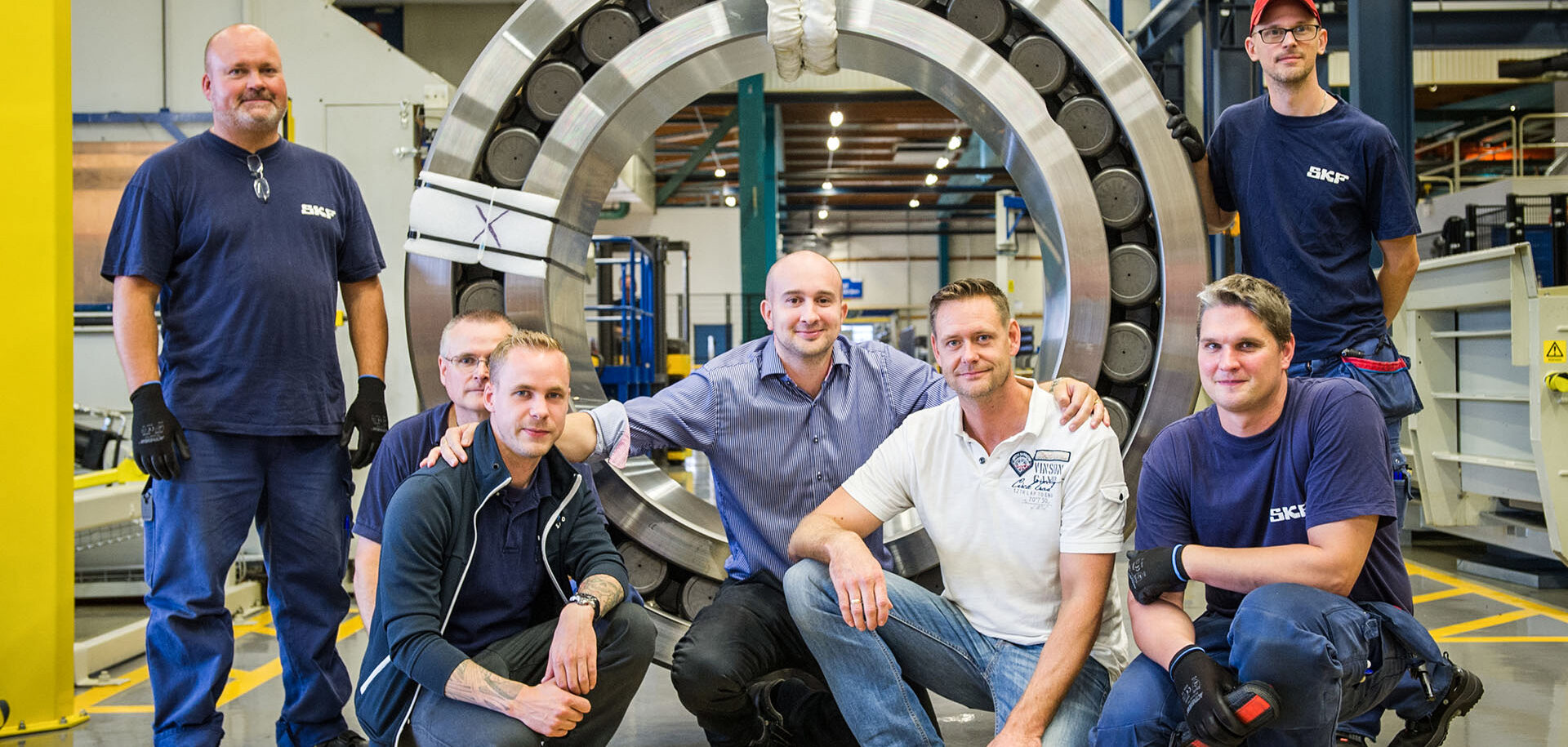

In a very different application, SKF in Gothenburg made one of the largest spherical roller bearings for the mining industry. It was produced in 2017 and weighs 7.8 tonnes (each rolling element weighs 42 kilograms). It has a bore diameter of 1,250 millimetres. The bearing is equipped with SKF SensorMount, a unique system that measures the actual mounting fit of the bearing onto the shaft. It helps avoid the risk of improper mounting, a major issue for large-size bearings.

Latest designs

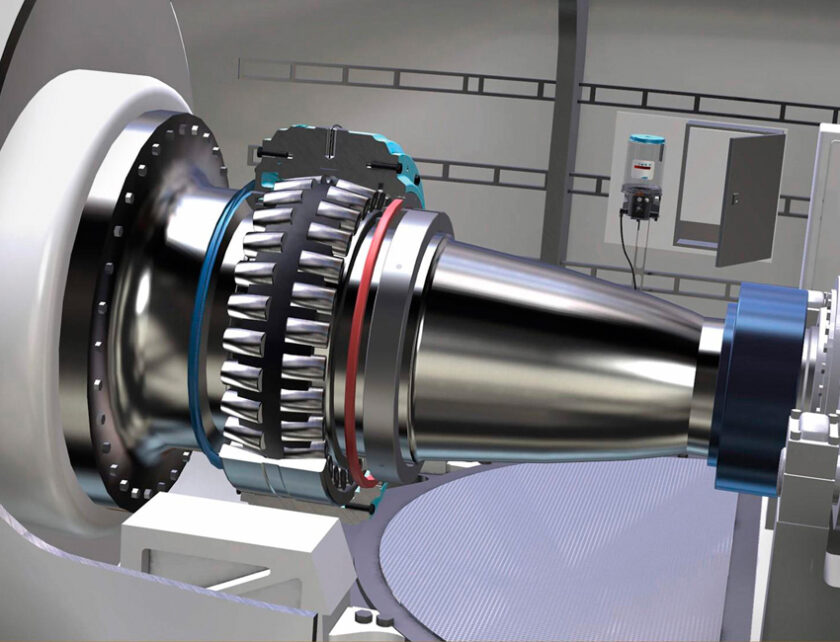

As with all of SKF’s products, spherical roller bearings have undergone continual development, most recently in 2018 with the launch of a new SKF Explorer spherical roller bearing for high-speed applications targeted at the industrial gearbox sector. The future of the spherical roller bearing means continually pushing the boundaries of performance.

Keep me updated

Sign up here for EVOLUTION updates to receive new content directly to your inbox.