New solution for wind turbine operators

In partnership with Boralex, a leader in the Canadian renewable energy market and France’s largest independent producer of onshore wind power, SKF is developing a new dashboard to help wind farm operators optimize the proficiency of wind turbines.

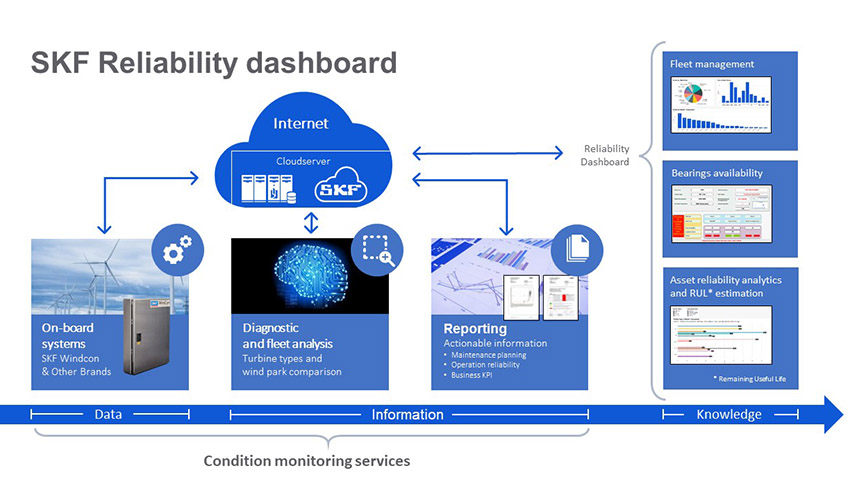

The Wind Reliability Dashboard is an evolution of SKF’s current condition-monitoring and predictive-maintenance tools. It extends existing capabilities by allowing data to be captured and analysed from all forms of rotating systems in each turbine, both from SKF and from other condition-monitoring system (CMS) providers.

The dashboard also captures information from maintenance systems as well as from the supply chain, allowing an operator to, for example, match the lead time required to acquire replacement spare parts with the remaining useful life of the component.

The Wind Reliability Dashboard is currently being tested in the field by Boralex, SKF’s development partner.