Turning the tide

Tidal energy has been identified as a potentially important global source of sustainable renewable energy. A Scottish company and SKF are collaborating on a joint project to use floating tidal turbine technology to reduce the costs of generating electricity.

European Ocean Energy ERA-NET

Ocean Energy ERA-NET coordinates funding programmes between European countries and regions related to ocean energy research and innovation. The aim is to help maintain and grow Europe’s world-leading position in ocean energy, bring innovative, low-carbon energy solutions closer to commercial deployment, reduce energy costs and create growth and jobs. Eight national and regional government agencies have received funding from the European Union under the Horizon 2020 Programme for Research and Innovation. They are the Basque Country in Spain, Brittany and Pays de la Loire in France, as well as Ireland, Portugal, Scotland, Spain and Sweden. The project brings together Orbital’s core supply chain and strategic partners to deliver a future-proofed product solution with a much-reduced risk profile that is easier to finance.

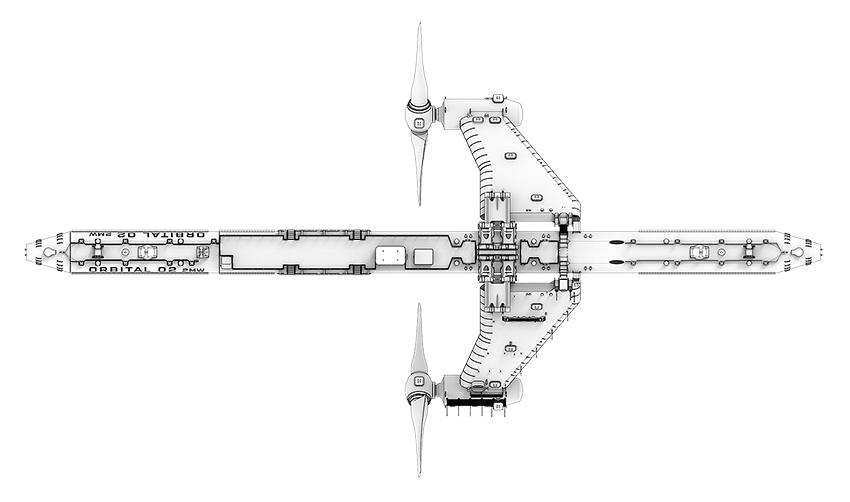

One key to the commercialization of tidal turbines is the development of a pitch controller for the tidal turbine blades. “We are targeting up to a 50 percent increase in yield from our machines, bringing our performance firmly in line with more established technologies,” says Scott. The European Ocean Energy ERA-NET Cofund (see fact box) has given a 1.2 million euro research grant towards the development and delivery of the pitch controller, which is being integrated into Orbital’s new floating tidal turbine, the Orbital O2 2MW.

We are targeting up to a 50 percent increase in yield from our machines.

Andrew Scott

CEO

“The easiest way for us to reduce the overall cost of energy is by being able to use longer rotor blades so they capture more energy from the tidal current,” Scott explains. “However, as the blades get longer the resulting loads become heavier and more challenging. A pitch controller system enables us to feather the blades such that we can control those loads far more accurately – an important solution to improve the economics of tidal energy.”

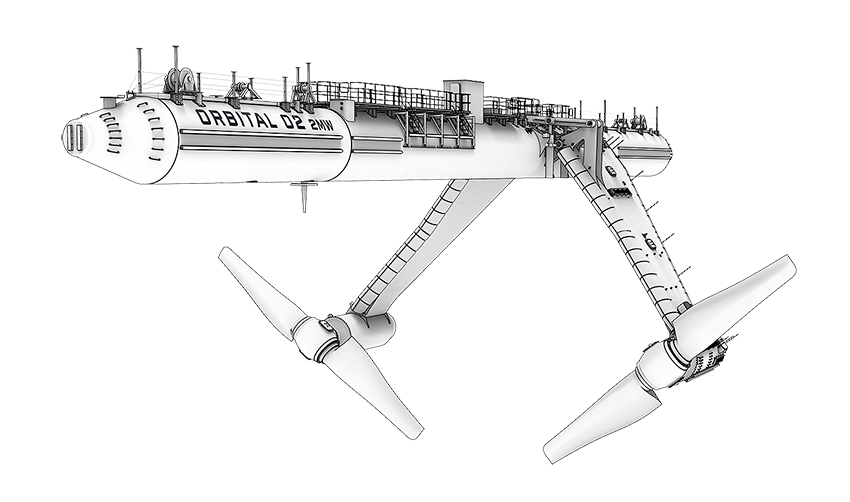

Because the technology is floating, all components and systems are readily accessible for maintenance, inspection and repair with minimal downtime, using only standard vessels. The technology is installed similarly to mooring a ship on a simple anchor arrangement, Scott says. “Alternative technologies with similar installed capacity fixed to the seabed are locked into using expensive vessels and equipment to recover them as they can’t be accessed while they’re fixed to the seabed,” he says. “This leads to a secondary problem of long periods of outages to access, recover and then repair turbines. Our costs are a fraction of our competitors’, and ultimately a totally different risk profile for investors and the supply chain.”

We will see markets grow as investors and governments increase their confidence and awareness of the solution that tidal energy can offer.

Andrew Scott

CEO

The turbine has been tested at the European Marine Energy Centre on the Orkney Islands, north of the Scottish mainland. “The Orkney Islands have a massive tidal stream resource, also known as the ‘Saudi Arabia of Tidal Power’,” says Scott. “The turbine was installed onto an existing subsea cable in one of the main tidal stream locations in Orkney, which let us export power to the local grid. This has been the test ground for the technology to operate in and provide all the valuable data required to validate performance, with the plan being to operate it for up to 15 years so we get good data sets for longer-term reliability and performance.”

Scott explains that the project will help Orbital Marine build experience and apply that to the engineering process to reduce costs. “In parallel,” he says, “we will see markets grow as investors and governments increase their confidence and awareness of the solution tidal energy can offer.”

SKF pitch-control modules

The pitch-control modules for the Orbital Marine technology will be delivered by SKF’s advanced solutions factory in Gothenburg, Sweden. The controller rotates two sets of blades with 20-metre rotor diameters about their longitudinal axis. The flow profile can adapt to the existing tidal stream speeds. By regulating the angle of attack, a constant power input above the rated tidal stream speed can be realized.

Michael Baumann, Business Develop-ment Manager for Marine and Ocean Energy at SKF, says, “Our dedicated Ocean Energy team works collaboratively with the most advanced tidal turbine prototype device developers and sub-component suppliers to help them design in reliability at an early stage.” Because wind turbines and ship propulsion systems such as electrical pods have similar challenges to overcome, SKF can bring this technical knowledge to tidal stream turbine applications.

Direct benefits include improved control of drivetrain torque forces, facilitating a 50 percent increase in the swept area of the device (16- to 20-metre rotor diameter) and resulting in a similar level of yield increase to Orbital’s current turbine configuration. It offers enhanced blade control around the rated speed to reduce power shedding and smooth power fluctuations, lowering extreme loading and fatigue on the drivetrain and structure, with increased environmental shutdown limits and the ability to continue generation in the event of a minor malfunction.

SKF has worked with Orbital Marine on a range of small- and large-scale demonstrator turbines, including the record-breaking SR2000. “SKF sees tremendous potential in floating tidal technology, due to its low installation and operating costs,” says Baumann. “We’re delighted to be bringing our experience to bear in delivering a key enabling solution to drive cost reductions and accelerate the rollout of Orbital Marine’s floating tidal technology.”