Noise and vibration measurement for aerospace maintenance services

The aerospace industry has extremely stringent requirements relating to maintenance. Increased vibration can often indicate a potential problem in key aircraft components such as gearboxes.

The aerospace industry has extremely stringent requirements relating to maintenance. Increased vibration can often indicate a potential problem in key aircraft components such as gearboxes.

SKF uses its vast experience of bearing analysis to support maintenance services, and Rolls-Royce Deutschland has now certified its equipment for testing.

Periodic inspection, functional testing and maintenance of all relevant components in the aerospace industry ensure safety and reliable operation of the equipment and can lead to cost savings through extended service life. For the re-use of components in aerospace applications such as turbines or power systems, it is of utmost importance to apply the best available processes and tools for quality inspection.

As the leader in rolling bearing technology, SKF has comprehensive knowledge of bearings and a deep understanding of bearing noise and its root causes. Bearing vibration analysis is mandatory in the group’s own production processes, and its equipment can be used for bearing inspection during maintenance and refurbishment services. Unreliable bearing performance can be caused by wavy components, by local defects at rings and rolling elements and by dirt particles in the bearing. All of these bearing quality issues can be tested and detected with the SKF Bearing Vibration Analyser.

General

Vibration measurement is of great importance for high-quality bearing production. Some types of vibration are related to diminished bearing life and can be a source of customer dissatisfaction. Vibrations in bearings are caused by time varying forces in bearings. The contact forces move around the bearing, giving rise to perfect bearing vibrations in the outer ring. Unreliable bearing performance can be caused by:

-

Waviness

-

Local defects

-

Dirt particles

-

Roughness

-

Form errors

-

Cage problems.

Noise and vibration equipment developed by SKF can quantify and trace the reasons for the vibrations.

History

SKF developed and produced its first vibration equipment for controlling noise quality of bearings as early as the mid-1950s. It was the result of research work to understand the vibration behaviour of bearings. In 1965 SKF’s E. Yhland reached a milestone in the understanding of the quasi-static problem of bearing vibration, helping to contribute to national standards such as AFBMA 13-1987 and DIN 5426 (draft) that define and specify the physical quantities to be measured and the test conditions to be applied.

Principle

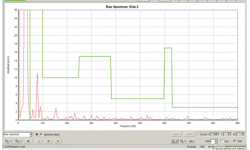

In practice, special sensor equipment measures radial vibrations of the outer ring. The bearing is fitted to a precise spindle and rotates at 1800 r/min. The outer ring is stationary and loaded by a loading tool. The signal from a pick-up is amplified and passed to three wideband filters, the low (L), medium (M) and high (H) band, which comply with the AFBMA and DIN standards.

In SKF noise and vibration equipment, the vibration from a bearing is transformed into electrical signals by a specially developed pick-up, working according to the inductive principle. The very small

velocity proportional signal must not be drowned by noise or other surroundings in the factory environment, so a highly sensitive low-noise amplifier is integrated into the pick-up. The analogue signal from the pick-up is then digitized by a high-resolution analogue-to-digital converter for further computer processing.

Special SKF measuring electronics provide much more information in the narrow-band spectrum than the broad-band parameters L, M and H. These results can be shown in µm/s or Anderon units.

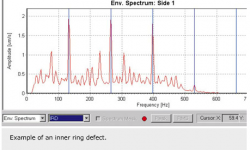

Using a time domain, enveloping techniques, narrow-band frequency analyses, Fourier transformation, spectrum mask and a special digital filtering technique, FPM, the different signal frequencies corresponding to a bearing component (inner ring, outer ring, ball) can be measured and analyzed.

The result identifies one or more of a possible number of defect types. Further, the SKF electronics is able to detect dirt components, cage noise and form deviations of components of a bearing.

Rolls-Royce homologates SKF for noise-testing equipment

Equipment based on this technology has been certified by Rolls-Royce noise testing during gearbox servicing. The certification took place following the decision by Rolls-Royce Deutschland to transfer service work on gearboxes for secondary power systems to the sub-contractor DARA in Almondbank, Scotland. Overhaul of the gearboxes (right- and left-hand) requires detailed inspection of more than 3,000 components; in some cases this requires specialized equipment. An example of this is the stringent noise and vibration testing and the measurement of the radial and axial clearance of the various types of rolling bearings in the gearbox. Before February 2006, DARA sent bearings to Rolls-Royce Deutschland for testing, as there was no bearing test equipment available at Almondbank.

Now DARA has selected SKF as the best suitable supplier for testing equipment for bearing noise and axial as well as radial clearance. To do this, it was necessary to run a certification process with Rolls-Royce Deutschland for this special measurement equipment. Commissioning of this equipment involved a detailed test and acceptance programme, developed by Rolls-Royce Deutschland, using reference and series bearings to confirm the usability of the noise-test equipment after its installation at the DARA site.

The Quality Technology Centre based at SKF in Steyr, Austria, successfully passed the acceptance programme with Rolls-Royce Deutschland, and the equipment was installed at DARA in early 2006. In addition, SKF is the approved supplier of noise-testing equipment to Rolls-Royce Deutschland.