Fault detection for mining and mineral processing equipment

Additional faults such as the loss of screen vibration due to the failure of a transmission belt or coupling are also possible to detect.

Fault detection is a technique being applied in the mining commodities industry to lower operating costs and improve machine reliability and efficiency.The mining, aggregates and cement industries are looking to contain and reduce costs in the face of long-term market price declines in their products. Over the past seven years, for example, the average U.S. price of coal has dropped by 30 percent, while operating and environmental costs have increased. The mining and mineral processing industry has looked to consolidation, improved machine reliability and efficiency and has reduced expenses to sustain profitability.

Condition monitoring and fault detection can support these actions by extending equipment performance, preventing unplanned downtime and reducing maintenance and repair time. Though well established in process industries such as pulp and paper, steelmaking and petrochemicals, such technology is not well applied in the mineral processing section of the mining, aggregates and cement industries. This is partly related to the traditionally high cost of condition monitoring and the harsh machine environment. Also, high vibration in vibrating screens, grinding mills and crushers has been a deterrent to widespread condition monitoring.

SKF, through the development of its SKF Copperhead fault detection and bearing system for vibration screens, has helped overcome these disadvantages. It detects process faults that may cause damage and affect operation of equipment. The first application was for vibrating screens that are used widely in the mineral processing industry. The bearing system extends the service life and improves the performance of the vibrating screens.

The SKF Copperhead concept uses a specially developed vibration and temperature sensor permanently mounted on the vibrating screen. The sensor is designed to operate in harsh environments and is linked to either a periodic or continuous monitoring system.

Acceleration enveloping

The system applies the SKF acceleration enveloping technology. This technique can differentiate between normal vibrations due to the passage of minerals through the machine and abnormal vibrations due to machinery process faults such as a loose mesh or “bottoming out” in a vibrating screen. The main focus of the fault detection system is continuous monitoring and the detection of process faults. Such systems can also detect machinery faults such as gear, lubrication and bearing faults. Here, the system alerts the machine operator to abnormal vibrations so that they can be investigated and eliminated before damage results. The rugged accelerometer and temperature sensor can withstand the high vibration in the vibrating screen. The accelerometer/temperature sensor is also suitable for mills, crushers and other mining applications.

In addition to these performance benefits, safety in the mining and quarrying operation can also be improved. Some practical examples demonstrate the effectiveness of this technique.

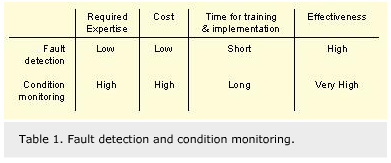

Condition monitoring and fault detection are two approaches to identifying potential problems early. Generally, condition monitoring is a relatively high-cost, high-skill approach using sophisticated instruments that has value in industries such as paper mills.

Fault detection usually has a lower overall cost than condition monitoring and can be implemented immediately without much training. It is not dependent on the development or skill of a specialist and is a valuable tool in price-sensitive applications.

Fault detection can be either periodic or continuous. It does not generally include the determination of the root cause of the fault. Fault detection can be tuned to include the machinery process and condition faults.

Vibrating screens and feeders

Vibrating screens and feeders are key components in the mining and mineral process, waste management and construction industries. The screen sorts or cleans material for the metals, aggregates, cement and mineral process. Usually, the screen (and feeder) is made of a structural frame supported on springs or other elastic material. Additionally, the screen frame includes a mesh (cloth) or grating that sorts or sifts the material. Material (stone, ore, cement) is dropped into the top of the screen onto the mesh. The sorting and sifting process is sped up by the vibration of the screen frame. To obtain the desired vibration, a rotating unbalanced mass is employed. One or two unbalanced shafts supported on bearings or vibratory gearboxes are used. Oversized or dirty material is separated for re-processing or is discarded.

Malfunction or loss of screen and feeder use can severely interrupt the processing of material as well as the productivity of the plant. Costs of a new screen can range from 25,000 to 150,000 US dollars. Downtime costs for a vibrating screen can vary from USD 100 to 15,000 per hour, depending on the type of process. Screen repair can take from one to 48 hours, depending on the problem and the maintenance setup.

Screens or feeders are normally designed for vibrations in the range of 2 to 10 g acceleration, which corresponds to the 3 to 20 mm stroke or displacement of the screen. The vibration is generally sinusoidal, owing to the rotational unbalance of the eccentric mass. Additional vibrations occur in the screen, due to the loading and sorting/screening of the material in the machine. The high vibration in the screen and the abrasive characteristic of the sorted material cause high stresses and wear in the screen frame. The dusty and sometimes wet conditions make it difficult to keep the screen bearings clean. Bearings with special cages for vibrating applications and other features are needed because of the high acceleration forces in the screen. The SKF Copperhead bearing system includes the SKF Explorer-quality bearing for vibrating applications and the SKF CARB® toroidal bearing. The bearing system virtually eliminates the possibility that parasitic forces can be applied to the bearings, resulting in long service lives and cool operating temperatures. The SKF Explorer bearings for vibrating applications are denoted with the VA405 and VA406 suffix.

Typical process and machinery faults for vibrating screens and feeders include:

- Bottoming out. Material accumulates under the screen and interferes with the free motion of the frame. The screen frame strikes the material, causing uneven motion and possible distortion of the frame. This in turn causes structural damage to the frame and interferes with the sorting process, thus causing a change in the quality of the process.

- Overload. Too much material is loaded into the screen, which compresses the suspension of the frame. This has the same effects as bottoming out.

- Loose frame members. This occurs as the result of wear, fatigue, corrosion and overload.

- Loose screen mesh. A major cause of screen downtime, this occurs because of wear and inadequate tightening of the mesh.

- Gear damage. This results from fatigue, contamination and wear.

- Lubrication distress. This occurs because of contamination or loss of lubricant through the bearing housing sealing.

- Bearing damage. This is a result of high forces due to screen process faults (bottoming out), fretting corrosion on the shaft, fatigue, contamination, lubrication distress and wear.

Additional faults such as the loss of screen vibration due to the failure of a transmission belt or coupling are also possible to detect.

Fault detection

The technique for the detection of process and condition faults includes the permanent mounting of special heavy-duty vibration and temperature sensors on the screen, which are monitored by a demodulating filter module. The sensors measure the overall vibrations in the screen. The demodulating filters evaluate signals in the frequency range of 200 to 12000 Hz, with the observed normal vibrations demodulated from the spectrum.

A fault is detected as repetitive high frequency “bad” vibration in the screen, and the overall value of the demodulated signal increases. This increase in vibration trips an operator alarm so the cause of the fault can be investigated. Often, the operator can determine the cause of the fault without specialized instruments. The fault can be rectified, thus reducing the period that the screen operates with the fault and reducing the wear and tear on the screen. If the operator cannot locate and eliminate the source of the fault, a condition-monitoring specialist can be contacted to make further measurements.

The fault detection system works using electronic filtering. The filter looks at vibrations in the frequency range where the faults occur and ignores frequencies that are uninteresting. The important frequencies are further processed and compared to an alarm set point in the system. If the overall bad-vibration level exceeds the alarm point, the operator is alerted.

A limiting factor to permanent and continuous monitoring is improper installation of temporary sensors – for example, because of a poor mounting surface or debris between the sensor base and the screen. Protective guards can also hamper correct placement of the sensor, or the rotating shafting itself can make the sensing location less than optimum for good measurements. Mounting the temporary sensor can expose the worker to hazards from falling rock and debris. The repeatability of the measurements from one time to the next may be unreliable. Permanently mounting the sensors avoids the need for workers to access screens located in difficult positions.

System specification

The sensors for mining and mineral applications have to be rugged, with high shock and over-voltage protection. A sensor should have an integral cable for connection to the monitoring system that is also abrasive-resistant and has a high fatigue resistance. An integral cable avoids a cable connector, which can become damaged by vibration. Performance at the connecting point can also be affected by dirt and moisture near the screen. The sensitivity of the sensor should be high enough to detect the various vibration levels in the screen.

Periodic monitoring can be performed with a portable data logger/spectrum analyzer. This logger, if fitted with the correct demodulating filter, can evaluate the screen vibration signal and determine if faults exist, while the analyzer can determine the type of fault.

In operation, a continuous monitoring system filters and demodulates the vibration signal, has alarm setting capabilities and can provide an output signal for monitoring. The continuous fault detection system should have a 4 to 20 mA output signal that can be continuously monitored by the plant’s programmable logic controller (PLC) or distributed control system (DCS). The PLC or DCS can also monitor the temperature output signal from the sensor. Continuous monitoring by the PLC or DCS reduces the need for operators to make periodic measurements on the screen. The system can also trip an alarm to alert the operator to a fault in the screen. With this information, a decision can be made to shut down the screen or stop the feed to the screen.

The fault detection system was first evaluated at a copper mine in Arizona in the United States. It was able to detect the loose mesh and bottoming out on an operating screen. As the screen was used for production, limited time was available for field-testing. To support this, a vibrating screen test rig was developed in the SKF laboratory. Most screen faults could be reproduced on the test rig. The system was refined before use in other mines and quarries.

Installation on vibrating screens

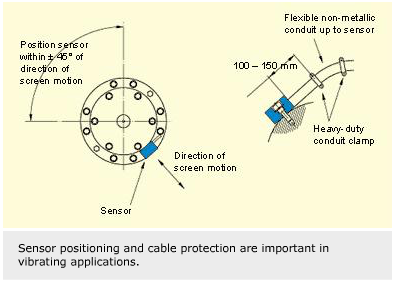

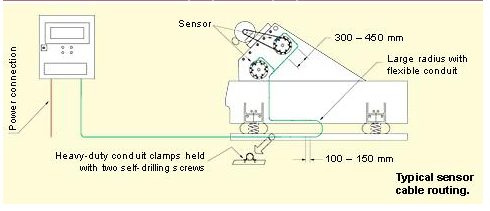

The fault detection system must be installed so that the components are securely attached to the vibrating screen and protected from mechanical damage. Sensors should be located close to the screen bearing housings and oriented in the direction of the screen stroke, plus/minus 45°. Also, the sensors must be protected from impact from falling stone or debris, and the sensor cable should be protected from mechanical damage and abrasive wear. The sensor cable must pass from the moving screen structure to the stationary frame without damage from the motion of the screen or stress in the cable. A large radius for the sensor cable must be provided between the moving and stationary parts of the screen.

Fault detection based on the SKF Copperhead design has been applied to a number of vibrating screens worldwide. As an example, three cases demonstrating benefits to the screen operator are given. One is in a copper mine and two others are in aggregates plants.

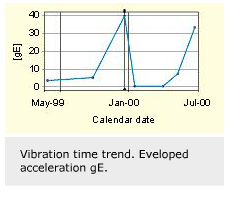

A fault detection system was installed on a vibrating screen at the copper mine in October 2000. The screen had recently been rebuilt after a failure on one of the two exciter mechanisms. The new mechanism had a normal vibration level, whereas the original mechanism had had a high vibration level. The fault detection system was set to alarm if the vibration in the mechanisms exceeded 33 gE vibration. In January 2001, the system alarmed high vibration in the original mechanism. The vibration level was in the range of 49 gE. The customer was advised to remove the screen from service to avoid an unplanned or catastrophic failure.

In August 2000, a fault detection system was installed on a vibrating screen at a major aggregates plant in the United States. During installation, it was noted that the drive side bearing had a slightly higher vibration level than the vibration level in the opposite bearing. This was likely due to a slight mechanical looseness. In December 2000 the vibration had increased significantly as indicated by the sharp increase in overall acceleration value, gE. The screen was taken out of service as part of the plant’s overall reconstruction. Because of the “value” found with this initial detection system, the customer will install another fault detection system on the two new screens that will be part of the reconstructed plant.

The third system was a periodic fault detection system that was installed on a vibrating screen at an aggregates plant in Australia. The sensors were mounted on the screen, and a data logger/analyzer analyzed the machine periodically. Using the technique, a fault was observed in one of the spherical roller bearings as an increase in overall vibration level. The bearing was replaced in a planned way, with a minimum of costs.

Conclusion

Fault detection based on SKF Copperhead is an alternative approach to monitoring machinery and has a lower cost than condition monitoring. It has been proven to be an effective way to improve the performance and reliability of the vibrating screen in the minerals-processing sector. The ability to detect process and machinery faults and to alert the screen operator means that faults can be eliminated and scheduled maintenance or repair can be planned more efficiently. Thus, the reliability and safety of the monitoring is improved, providing that the system is properly installed. The SKF Copperhead bearing system extends the service life and performance of the vibrating screen. SKF Copperhead is being developed for use in other mineral-processing equipment applications.

Keith E. Meyers,

Program Manager, SKF Copperhead, Kulpsville, Pennsylvania,

and Matt Yeknik, SKF Mining & Construction, Phoenix, Arizona.