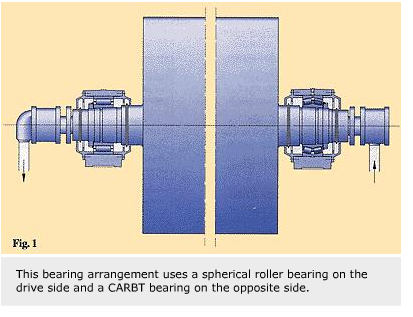

CARBTM is not only a versatile bearing that combines features of several bearing types, it is also a bearing that offers low friction and smooth running combined with greater tolerance under difficult operational conditions.These features have resulted in the CARBTM bearing becoming a popular non-locating bearing, even though it has been on the market for a relatively short time. For example, the first papermaking machine in the world to exceed a paper speed of 100 km/h for newsprint at Braviken in Sweden was equipped with CARBTM bearings.

The reliability of the non-locating bearing arrangement is particularly important for papermaking machinery where unplanned standstills can lead to considerable costs in terms of lost output. The bearings must be capable of withstanding temperatures of up to 130 °C, axial displacements of up to 15 mm and misalignment angles of up to 0.3° without this affecting service life or the amount of vibration produced. Previous solutions have been unable to meet such requirements completely or have resulted in a distinct reduction in running time as compared with the theoretical fatigue life.

Conditions in papermaking

In papermaking machinery, low-frequency vibrations have a significant impact on production. They can be caused by incorrect mounting or fluctuating operating conditions. For example, misalignment causes the rollers in cylindrical roller bearings to skew. This effect becomes more pronounced as the length-to-diameter ratio of the rollers becomes larger. The rollers form an angle with respect to the bearing axis and run against the flanges. This results in axial forces and vibrations caused by friction. If the inner rings of spherical roller bearings are mounted in a skewed position – for example, as a result of uneven distribution of the oil film on the journal during mounting – vibrations of double rotation frequency are produced. In the case of rocker housings, this can lead to very severe vibrations.

Tolerance

The CARBTM bearing is self-aligning, like the spherical roller bearing, to a misalignment angle of up to 1°, although it out-performs cylindrical roller bearings in its ability to cope with axial displacements of up to 10% of the bearing width without generating added friction or impairing service life. It has low friction and the highest load carrying capacity of all types of rolling bearings of the same cross section.

The rollers of the CARBTM bearings are self-centring. The bearing has no flanges or guide rings. As for deep groove ball bearings, which are often used when smooth running is required, the rolling elements in CARBTM always find a position in the bearing where the forces to which they are subject will have the least effect. This is always the case when the main axes of the contact ellipses in the rolling contacts for the inner and outer rings run parallel. The free running motion of the rolling elements prevents vibrations occurring through misalignment. CARBTM rollers do not skew.

As they automatically take up a position in which the load is distributed evenly over the length the roller, even mounting errors do not result in high vibration levels, as can be the case with spherical roller bearings if the inner ring is mounted out of true. The unforced guiding of the rolling elements means that any slight deformation in adjacent parts, such as bearing seatings with tapered outside diameter, are compensated for easily. The outer ring can be mounted with a tight fit as the displacement of the non-locating bearing takes place inside the bearing.

These features make the CARBTM bearing particularly suitable for high-speed machinery applications, now and in the future. In the paper industry, for example, machine manufacturers have become enthusiastic users of this bearing in drying cylinder bearing arrangements and their use is being extended for wire and felt rolls.

Few modifications

CARBTM can replace cylindrical roller bearings without the need for modification to housings, adjacent components or lubrication. If self-aligning cylindrical roller bearings are to be replaced, the lubricant inlet must be relocated and for the replacement of spherical roller bearings, two additional locating rings are also required. In drying applications, long, heated cylinders can experience extreme shaft expansion. Owing to the large distance between bearings, which can be 10 m or more, self-aligning bearings are essential. Although during production such expansion is largely constant, standstills can occur and the temperature can change dramatically. The CARBTM bearings allow smooth operation at high paper speeds, and it would be difficult to increase output and maintain paper quality without the performance that the CARBTM> bearing provides under such conditions.

Practical results

When papermaking machines fitted with CARBTM bearings were tried out on the shop floor, the decrease in vibration levels compared with machines with conventional bearings was noticeable. The first results from German machine operators indicate that vibration levels were reduced by 40% when cylindrical roller bearings were replaced and by up to 85% when rocker arrangements were replaced with CARBTM bearings. The benefits for the user are increased operational reliability and longer service life. In highly sensitive applications, there are also advantages in terms of product quality.

Wide scope

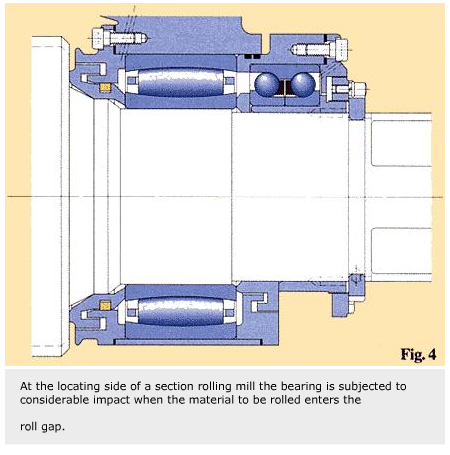

In addition to papermaking applications, the bearing has potential in gear applications or other machines. Many bearings in machinery are subject to short bursts of highly fluctuating loading, which results in deflection and skewing. Figure 4 shows the example of the locating bearing side of a section rolling mill. In this case the bearing is subjected to considerable impact when the material to be rolled enters the roll gap. Similar conditions are experienced in other rolling mill machines, such as breast rollers, roller tables or pinion stands. CARBTM has already achieved a dominance in paper manufacturing applications where it is used in more than 100 paper mills around the world. The use of this bearing is spreading throughout the engineering industry.

To meet this demand, a factory for the manufacture of CARBTM bearings has been opened in Gothenburg, Sweden, and the standard range available comprises about 30 sizes for shaft diameters between 50 and 300 mm.

Heinrich Winter and Karl-Friedrich Kaschube SKF GmbH,

Schweinfurt, Germany