Tapered roller bearing load ratings versus performance

Values of dynamic load ratings for tapered roller bearings listed in catalogues might be confusing and not comparable because manufacturers calculate to different standards. Important parameters are examined. SKF has now introduced a very large range of SKF Explorer tapered roller bearings for extended bearing life.

The natural environment of tapered roller bearings

Tapered roller bearings are very common in heavy-duty automotive and industrial applications. Applications can be found in car/truck transmissions and wheel-ends, metal and wind industries, material handling, mining and industrial transmissions.

Typical for these applications are the requirements to accommodate heavy combined radial and axial loads as well as operations with high stiffness. Reliability, durability and the capability to withstand extreme conditions are also important criteria.

Furthermore, and most often, tapered roller bearings operate under contaminated and harsh conditions where the main issue is to ensure uptime.

Load Ratings

Relevance of load ratings

When comparing bearings from different manufacturers, engineers often look at the load ratings as the substantial performance parameter [1]. The dynamic load rating is also key for calculating the bearing basic rating. This can be explained most easily from the life equation.

Calculation to ISO Standard

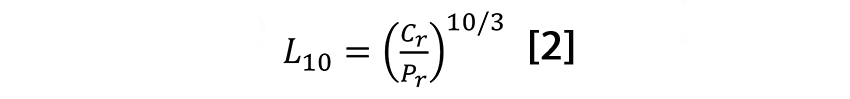

According to ISO 281, the basic rating life of a radial roller bearing is calculated from:

where

L10 = basic rating life (at 90 % reliability)

Cr = basic dynamic radial load rating

Pr = dynamic equivalent radial load.

According to ISO 281, the basic dynamic radial load rating for radial roller bearings is calculated from:

Cr = basic dynamic radial load rating

bm = rating factor of bearing type (value 1,1 for tapered roller bearings)

fc = material/geometry/dimension factor

i = number of rows

Lwe = effective roller length

Z = number of rollers per row

Dwe = mean roller diameter.

The relevance of fc as performance factor is very obvious, for example a performance factor of 1.23 results in double L10 basic rating life.

Calculations to US Standards

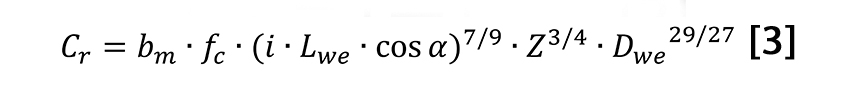

Sometimes, and especially in the North American market, C90 load ratings can be found. These are based on a rating life of 90×106 revolutions:

where

C90 = basic dynamic load rating based on 90×106 revolutions

M = material factor, defined by bearing manufacturer

H = geometry dependent factor, defined by bearing manufacturer

i = number of rows

leff = effective contact length

![]() = contact angle

= contact angle

Z = number of rollers per row

Dwo = mean roller diameter.

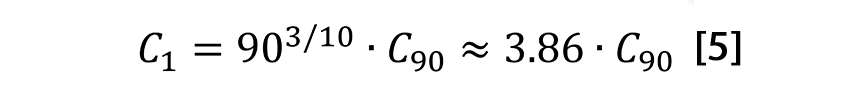

Dynamic radial load rating C1 for 1×106 revolutions rating life:

Comparison of load ratings

From the preceding it is clear that Cr load ratings according to ISO cannot be directly compared with US C1 load ratings. C1 values are converted from C90 load ratings and though they have a similar basic structure, the equations for Cr and C90 make use of different factors and exponents [6]. This results in a different weighting of the single geometry parameters.

Benchmark tests

Extensive benchmark tests with different tapered roller bearing types have been performed. Results for the tested bearing type 32011 X are commented hereafter.

Summary

C90 and C1 load ratings cannot be directly compared with ISO calculation methods.

It is of vital importance that bearing manufacturers back up their load-rating data with test results.

It is recommended to engineers to look at the printed C values in bearing catalogues with a critical eye and check them for consistency with ISO 281 or established bearing-manufacturer testing practices. One can easily check C values by measuring bearing component dimensions with simple methods; see [7].

Also, the more robust and reliable the load-rating data are, the higher the power density can be in the application [8].

The future challenge for bearing manufacturers is to come up with solutions that better represent the bearing field performance, to the benefit of customers.

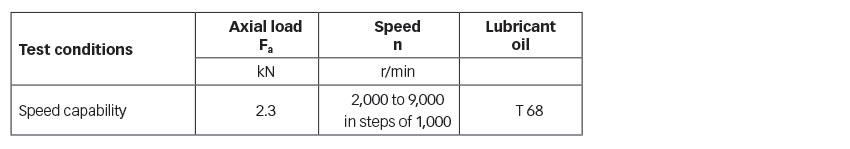

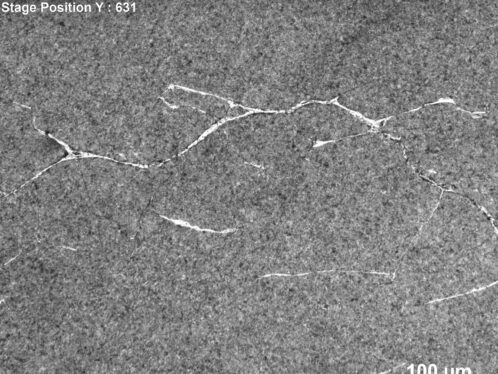

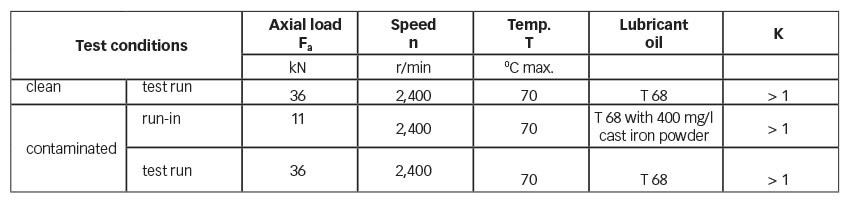

The benchmark tests have been performed for two cases: clean and contaminated operating conditions. Clean tests are performed with the bearing and oil in a newly manufactured condition, as is. For the contaminated tests, debris particles had been added to the oil and the bearing was run-in in this condition first. Thereafter, the contaminated oil was removed and the bearings were run with clean oil until failure. The test conditions are depicted in table 1.

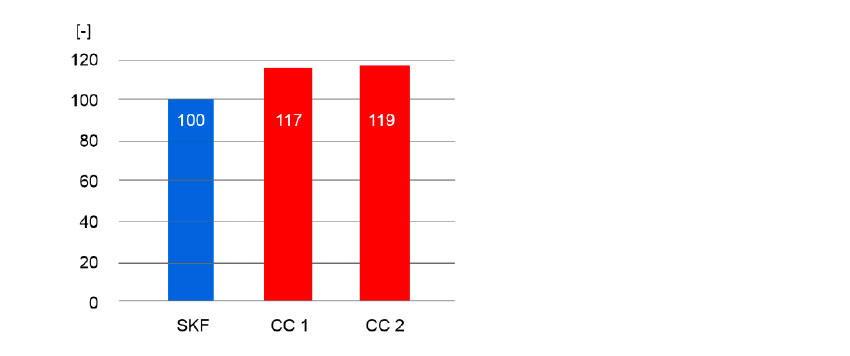

Fig. 1 shows a comparison of catalogue load ratings from SKF and two other bearing manufacturers. The reference value 100 is SKF. Compared with SKF, the two other bearing companies list load ratings relatively 17 % and 19 % higher than SKF.

Test results

Fig. 2 shows the benchmark test results from clean operating conditions.

Fig. 3 shows the benchmark test results from contaminated operating conditions.

Result: Despite the lower quoted capacity figures, the SKF tapered roller bearings performed significantly better than the competitor bearings in both clean and contaminated test runs.

Speed capabilities temperature tests

In addition to the benchmark life tests, speed capability tests also have been performed with bearing type 32011 X. A pure axial load of 2.3 kN has been applied to the test bearing before rotation started. Then, different speed stages have been applied from 2,000 r/min to 9,000 r/min, in steps of 1,000 r/min (fig. 4).

Test results

- SKF bearings operated at the lowest temperature levels at all speeds. Temperature differences increased at higher speed levels. At the maximum speed limit the mean temperature of SKF bearings was 11.5 °C lower than the mean bearing temperature of the nearest competitor (CC 2).

- For speed levels up from 4,000 r/min, competitor bearings progressively ran at higher mean temperatures compared with SKF.

SKF tapered roller bearings, new consolidated assortment and SKF Explorer

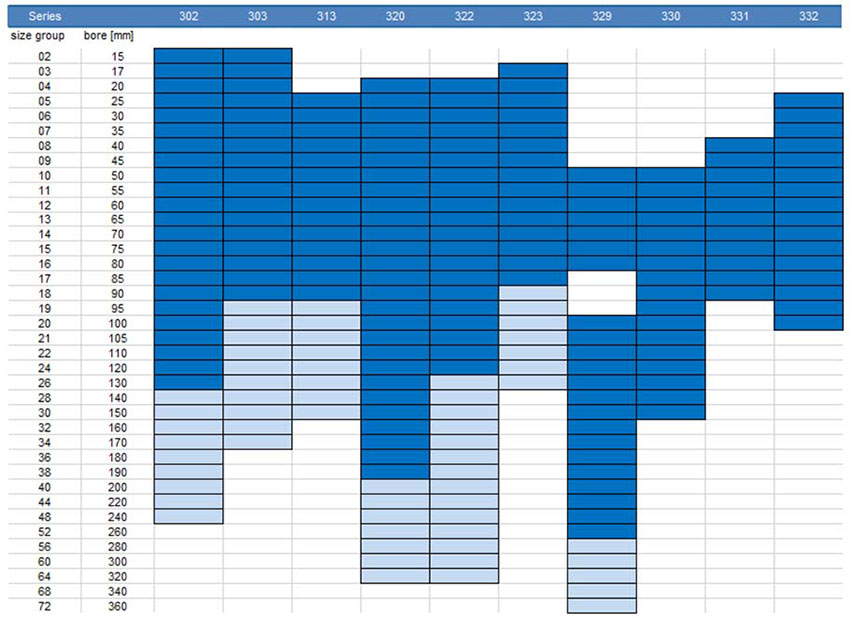

To better represent the actual performance of SKF tapered roller bearings, a new and consolidated catalogue assortment has been launched.

The main points are:

- a wide SKF Explorer assortment (fig. 5); small and almost all medium sizes all are SKF Explorer; the range is being extended continuously

- larger-size catalogue bearings, for the time being, remain SKF Basic design

- the catalogue range of inch-size bearings is being extended

- the industry preferred assortments and customized products (such as CL7C) will remain, but will not be part of the standard catalogue assortment.

An extended range of SKF Explorer tapered roller bearings – increased load ratings

Continuous improvements in manufacturing have made it possible to qualify a majority of the tapered roller bearing assortment in the standard rolling bearings catalogue to the SKF Explorer performance class. This includes all the previous TQ line items and a large number of additional items, mainly due to new rollers conforming to SKF Explorer performance class.

SKF tapered roller bearing benchmark test results conclude highly competitive performance on service life, frictional moment, noise and vibration levels and speed capabilities.

As in the past, all SKF Explorer roller bearings have been uprated with an increase of 15 % in dynamic load rating. This is obviously also valid for the catalogue assortment of SKF Explorer tapered roller bearings.

Customer benefits

The main advantages of SKF Explorer tapered roller bearings for customers include:

- improved reliability

- increased productivity

- a lower number of premature failures

- reduced noise and vibration levels

- the possibility of downsizing

- reduced lubricant and energy consumption.

SKF Explorer is a registered trademark of the SKF Group

![Fig. 2: L10-test results [h], bearing type 32011 X, from benchmarking under clean operating conditions.](https://evolution.skf.com/wp-content/uploads/sites/5/2018/10/tapered-roller-bearing-load-ratings-versus-performance-table-fig2.jpg)

![Fig. 3: L10-test results [h], bearing type 32011 X, from benchmarking under contaminated operating conditions.](https://evolution.skf.com/wp-content/uploads/sites/5/2018/10/tapered-roller-bearing-load-ratings-versus-performance-table-fig3.jpg)

![Fig. 4: Speed capabilities temperature tests – Mean operating temperatures [°C]: blue: SKF, grey: CC 1, black: CC 2; red: speed [r/min].](https://evolution.skf.com/wp-content/uploads/sites/5/2018/10/tapered-roller-bearing-load-ratings-versus-performance-table-fig4-en.jpg)