A mobile alternative to monitor wind turbines

Operators of wind turbines need to monitor their equipment to ensure optimal performance. Often this is done with permanent condition monitoring installations, but sometimes these are not suitable. In these cases, a mobile system can sometimes get the job done at a lower cost and with less effort.

But what if a wind farm’s turbines have not been equipped with a permanent CMS? A retrofit installation is possible, but the operator might not be able to justify the necessary capital investment because the farm is too old or the site is too fragile. In that case, a mobile CMS concept from SKF could be the right solution.

This means that an online CMS device that has been customized for temporary use will be installed for a limited period of time – from one hour to a few days, following an adequate process – ensuring results of a decent quality level in terms of issues detection and identification.

Reducing the risk of unplanned stops

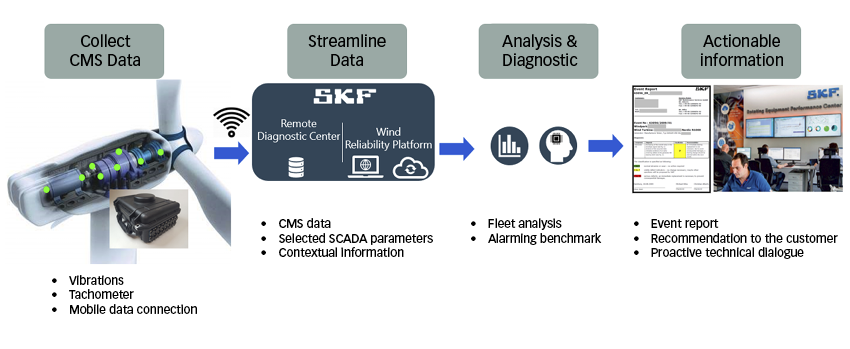

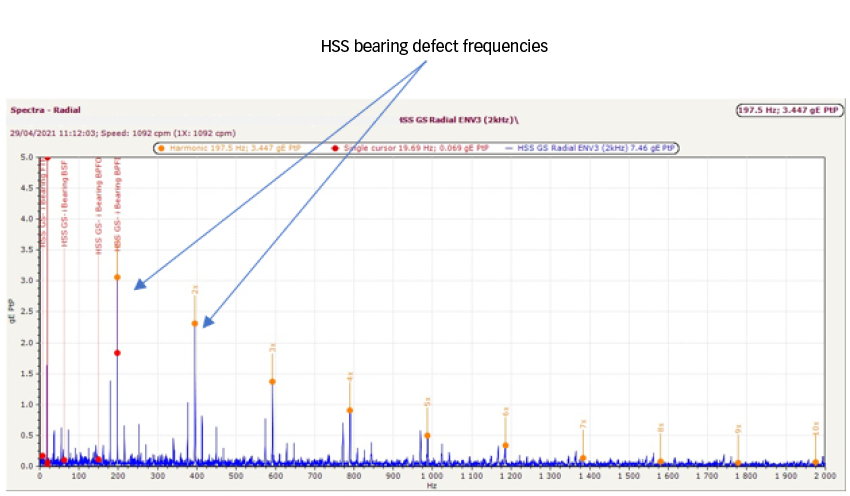

The mobile CMS collects data such as vibrations using a tachometer. The data is streamlined through a mobile data connection to SKF’s remote diagnostics centre. Contextual information about selected parameters is compiled and analysed from the data. Based on these findings, the wind farm operator is supplied with event reports and proactive recommendations for maintenance. This reduces the risk of unplanned stops and loss of revenues from the operation.

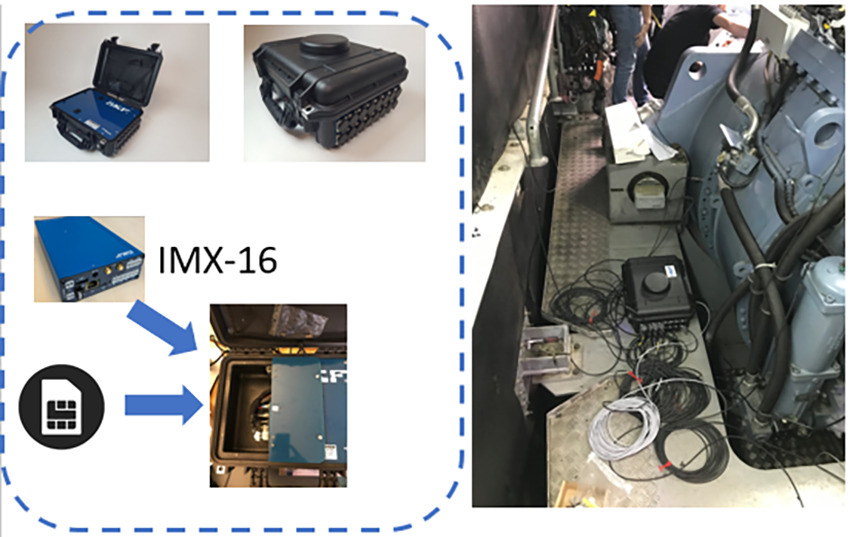

The mobile CMS device is the same as those installed in permanent systems, but it comes packaged in a rugged industrial case with splash-proof connectors, an integrated SIM card and an antenna slot for mobile signals.

Ensuring a proper evaluation

There are some key aspects to ensuring a proper mobile CMS evaluation of a turbine. Typical cases that the mobile CMS concept can address include performing a turbine end-of-warranty evaluation, checking the status of a new wind park, following up a specific mechanical issue, targeting a video inspection with a boroscope, sharpening a lubricant analysis or planning maintenance shutdown tasks.

Certainly, one cannot expect the same performance from a few hours of recording with a mobile CMS as with the long-term 24/7 monitoring of a permanent CMS. Permanent monitoring can ensure that all slight deviations are caught, allowing precise follow-up, and any mechanical degradation can be picked up and sent to the relevant personnel via an automatic alarm function.

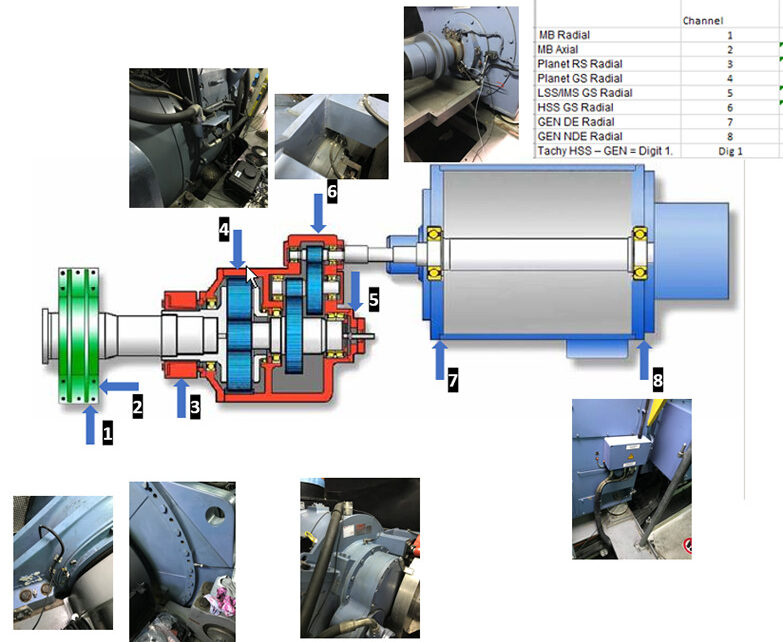

As with permanent monitoring, a mobile CMS needs to gather a minimum amount of information to limit the uncertainty of analysis. This information must include kinematic data such as asset models, gearbox speed ratios, bearing reference and turbine power curve. Ideally, it should also encompass technical track records such as the ages of the asset, component overhauls and lubricant analysis, as well as key selected parameters such as temperature and debris monitoring.

The positioning of the sensors is ideally adapted to the loading zones, depending on the design of the turbine drivetrain. Then a minimum amount of wind loading on the mechanical components is required to be able to detect and evaluate possible issues and to determine their severity. SKF proposes an inductive probe with a magnet holder that is linked to the mobile CMS system.

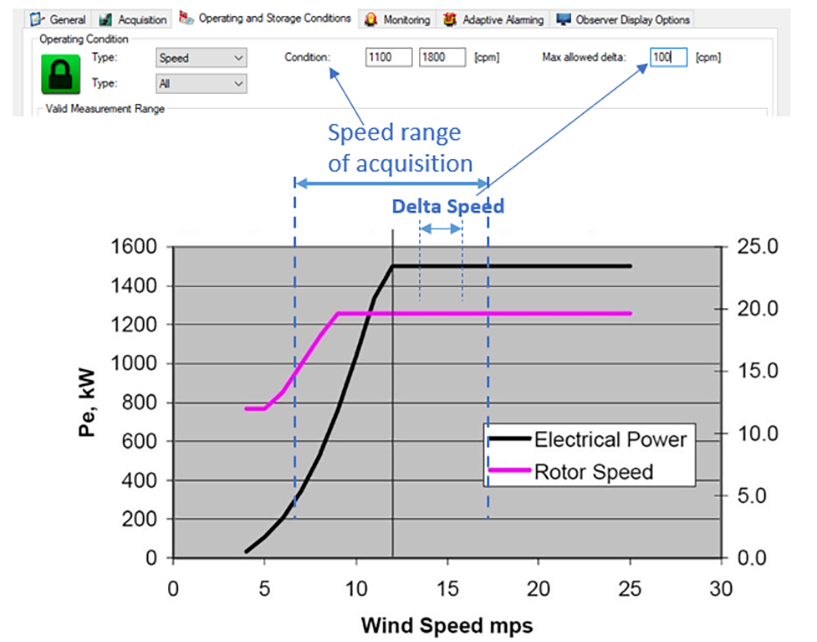

Wider speed-range area needed

A permanent CMS allows the operator to be selective in terms of data acquisition in relation to the speed and active power of picking up samples in similar loading conditions, leading to consistent trending. With mobile CMS it’s a bit more challenging. In view of the limited window of measurement, a wider speed-range area is needed. Classifying similar loading-condition records will be carried out afterwards with CMS software. However, one still needs to use the maximum allowable delta speed parameter, which protects against CMS data degradation that might occur as the wind fluctuates.

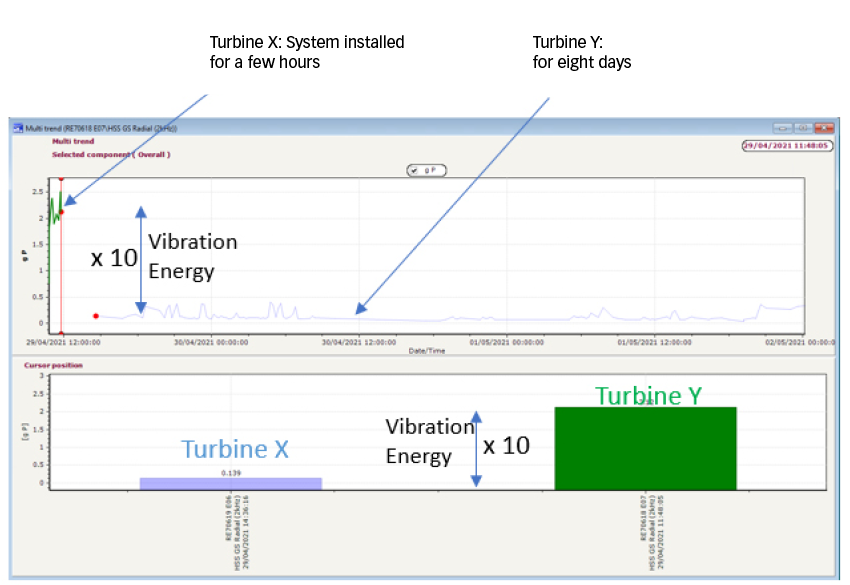

By following the mobile CMS process, it is also possible to compare the CMS values of particular machines, providing an overview of each component’s condition.

In addition, the mobile CMS provides accurate kinematic and qualitative measurements, reinforcing diagnostic accuracy and operation and maintenance decisions accordingly.

Conclusion

A mobile CMS can be a very good benefit-versus-risk operation, keeping in mind the use cases it is suitable for, and can be a valuable complement to existing O&M protocol.

It should also be noted that installation and measurement tasks can be carried out without requiring specific skills. However, the database creation, data analysis and data reporting are then managed by the specialist partner. Conclusions can be provided during the measurement campaign, as data is directly sent to the remote diagnostic cloud.