An ocean of power

The MeyGen project in Pentland Firth, Scotland, is the world’s largest tidal-stream project to date. It will have a huge significance for the future of sustainable energy supply.

With climate change being a pressing global threat to the world’s economy and environment, there is a strong need to deliver clean, renewable and sustainable energy. Tidal energy is one step towards a transition to a low-carbon economy and an increased renewable energy share for households and communities around the world.

Tidal energy is classified as an ocean technology that converts the energy caused by cyclical movements of the sea into electricity. There are three ways to generate electric energy from the tides; one of these is via underwater propellers (similar to windmills) powered by tidal streams.

This requires careful engineering, manufacturing and assembly, ensuring the reliable operation and high performance of the deployed technology.

Dr Carsten Hermann

of the Design and Development Department of Andritz Hydro in Ravensburg

The tidal turbines will be placed in the Inner Sound of the Pentland Firth, in the waters that separate the northern Scottish mainland from Stroma Island. It is home to whales and dolphins and other marine animals and is well known for its tidal streams, which are among the fastest in the world, with speeds of up to 18 kilo-metres per hour. With a suitable water depth of about 30 metres and very high flow velocity of up to five metres per second, it is potentially one of the best spots worldwide for tidal power generation.

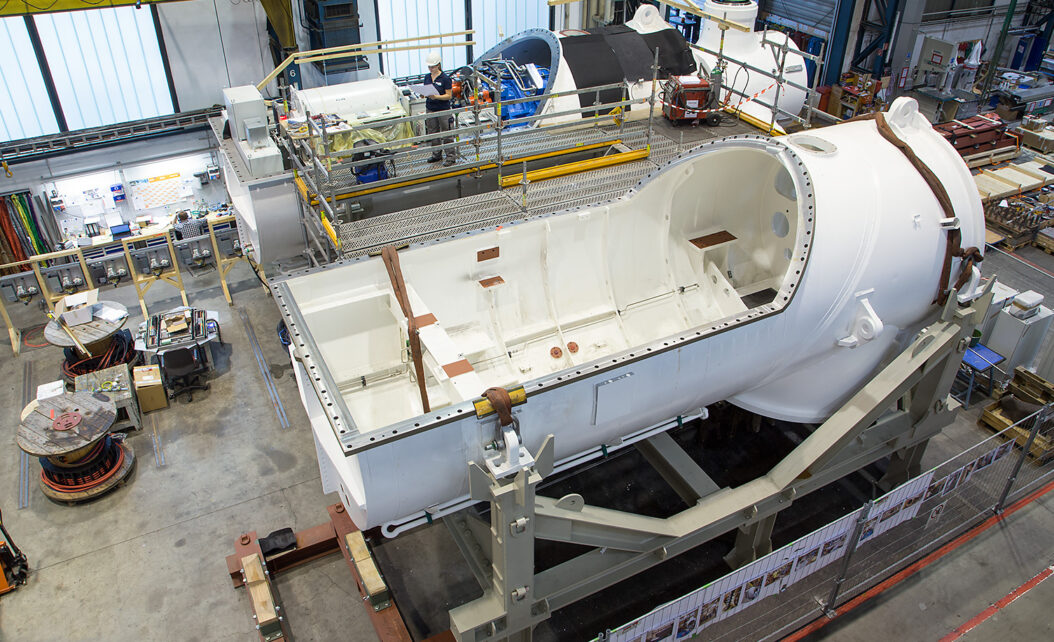

Nevertheless, the neighbouring Atlantic Ocean with its rough conditions makes the Inner Sound of the Pentland Firth one of the most challenging maritime environments on earth. As such, it is a complex location for operation that requires state-of-the-art machinery. “This requires careful engineering, manufacturing and assembly, ensuring the reliable operation and high performance of the deployed technology,” says Dr Carsten Hermann, of the Design and Development Department of ANDRITZ HYDRO in Ravensburg, Germany, where the turbines are manufactured. The components developed and delivered by ANDRITZ HYDRO have a predicted service life of about 25 years with a maintenance interval of five years.

Advances in tidal stream technology enable the production of a high degree of energy output. Few companies are developing expertise in this market, but ANDRITZ HYDRO has many years of experience in ocean technology. The company delivered and installed the entire electro-mechanical equipment for the world’s largest tidal power plant (254 MW) in Sihwa, South Korea. Most recently the company received an order for the rehabilitation of the tidal power plant in La Rance, France.

The design of the tidal turbines that are currently in production for the Penthland Firth is based upon the former prototypes that were tested in Kvalsund, Norway, installed in 2003 (300 kW) and at the European Marine Energy Centre, Orkney Islands, installed in 2011 (1,000 kW). In 2014, this development and know-how resulted in an order for the world’s first commercial tidal current power plant in Pentland Firth, Scotland.

A comprehensive offering

SKF has assisted ANDRITZ HYDRO with technical expertise, in particular in the design of the propeller shaft bearing arrangement, life calculations, both dynamic and static (safety) calculations, and the specific execution of the customized bearings. SKF also assisted with specific tools and specified mounting procedures for the propeller shaft bearings and a special front seal by SKF Marine.