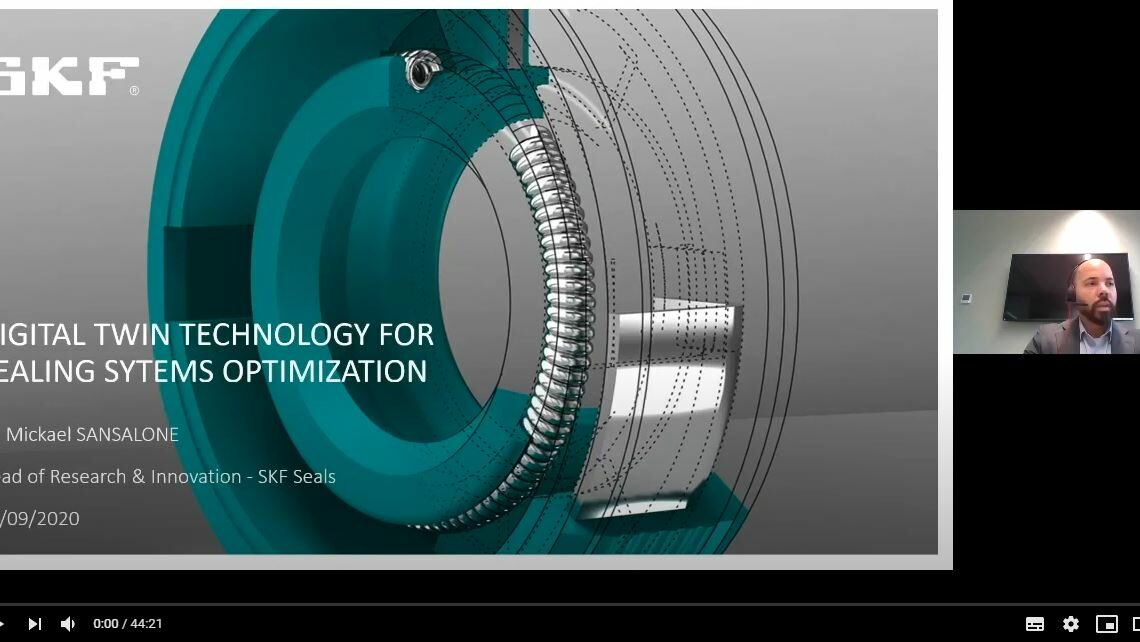

Digital twin technology for optimized sealing system

SKF Seals digital twin platforms combines advanced dynamic simulation methods with proprietary analytical models developed in-house which are crucial to reach high accordance between simulation and physical reality. Listen to this recorded webinar and learn more about how is specifically useful when testing is not capable of revealing the actual seal failure modes.

Prediction of lubricated seal friction and frictional heat generation are also included as part of the virtual optimization process. Consequently, this digital twin platform not only is helpful during the design phase of new components but is also perfectly suitable when troubleshooting existing sealing systems: to quickly encounter possible root causes and enable proper optimization within the shortest period of time. This is specifically useful when testing is not capable of revealing the actual seal failure modes. Listen to Mickael Sansalone, Manager Global Research & Innovation, SKF Seals, while he explores SKF Seals digital twin technology to reduce time-to-market and total cost of ownership for our customers.