Meeting the needs of today’s food and beverage industry

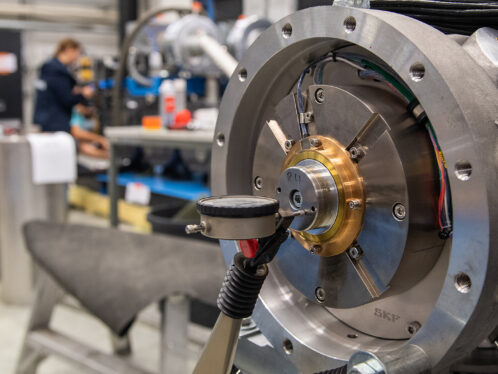

SKF food-grade seals are helping Laska push the frontiers of productivity, automation and hygiene in food production.

mechanical design engineer, Laska

2020 was supposed to be memorable year for Austrian manufacturing equipment specialist Laska. The family-owned company was celebrating 140 years in business, a period that had seen it grow from a producer of sausage skins to one of the world’s most important manufacturers of high-tech food-processing equipment, with customers in 140 countries.

Instead, the company’s anniversary year was memorable for rather different reasons. CEO Maximilian Laska, a member of the fifth generation of his family to run the business, faced the challenge of steering the company through the COVID-19 pandemic. Lockdowns and travel restrictions meant parties were put on hold, but Laska didn’t let the crisis put the brakes on progress. The company spent the year pushing on with multiple projects, such as introducing new IT systems and developing digital tools to help its sales and service teams connect with customers around the world.

2020 was supposed to be memorable year for Austrian manufacturing equipment specialist Laska. The family-owned company was celebrating 140 years in business, a period that had seen it grow from a producer of sausage skins to one of the world’s most important manufacturers of high-tech food-processing equipment, with customers in 140 countries.

Instead, the company’s anniversary year was memorable for rather different reasons. CEO Maximilian Laska, a member of the fifth generation of his family to run the business, faced the challenge of steering the company through the COVID-19 pandemic. Lockdowns and travel restrictions meant parties were put on hold, but Laska didn’t let the crisis put the brakes on progress. The company spent the year pushing on with multiple projects, such as introducing new IT systems and developing digital tools to help its sales and service teams connect with customers around the world.

mechanical design engineer, Laska

Modular design concept

In many ways the pandemic served to reinforce the value of Laska’s offering to those customers. “Food companies come to us for integrated production lines that can deliver highly standardized, high-volume production, with the option of adapting those lines over time,” explains Günter Leibetseder, mechanical design engineer at Laska. While Laska does make stand-alone machines such as meat cutters, grinders and mixers, it is increasingly focused on integrated and highly automated production lines, using a modular design concept that allows customers to extend or reconfigure their equipment in response to changing needs.

Seals are a key element in hygienic design.

Günter Leibetseder, mechanical design engineer, Laska

Automation has multiple benefits in food processing, including lower costs and tighter control over quality. But highly automated systems requiring fewer workers were especially beneficial during the pandemic, when food makers needed to operate with physical distancing at their facilities. And since that time, the high productivity of Laska’s automated systems has also helped customers operating in tight labour markets where workers are in short supply.

A clean start

Efficient production is only half the challenge in food manufacturing, however. The industry’s strict health and safety standards mean that equipment must be rigorously cleaned at shift ends or product changeovers. Improving the speed and effectiveness of those cleaning operations has been another key focus for Laska in recent years.

“Our customers want to make sanitization quicker and easier for their employees,” explains Leibetseder. “That’s very important, because often the cleaning is not done by specialists but rather by the operators who work on the line.” To address those needs, Laska is midway through a multi-year project to redesign all its machines using state-of-the-art hygienic design principles.

Hygiene has always been a critical factor in food production equipment design, and Laska’s machines already used food-safe materials such as stainless steel throughout their construction. But modern hygienic design takes things to the next level, with an intense focus on the smallest details of design, ensuring that machines have smooth continuous surfaces that are easy to wash, with no gaps or crevices where residues or bacteria can hide.

The first Laska machine to undergo a redesign was its range of grinders, used to produce high-quality minced meat for sausages, burgers and other popular food products. And it was the search for a critical element of that project that brought the Laska design team to SKF.

Seal of approval

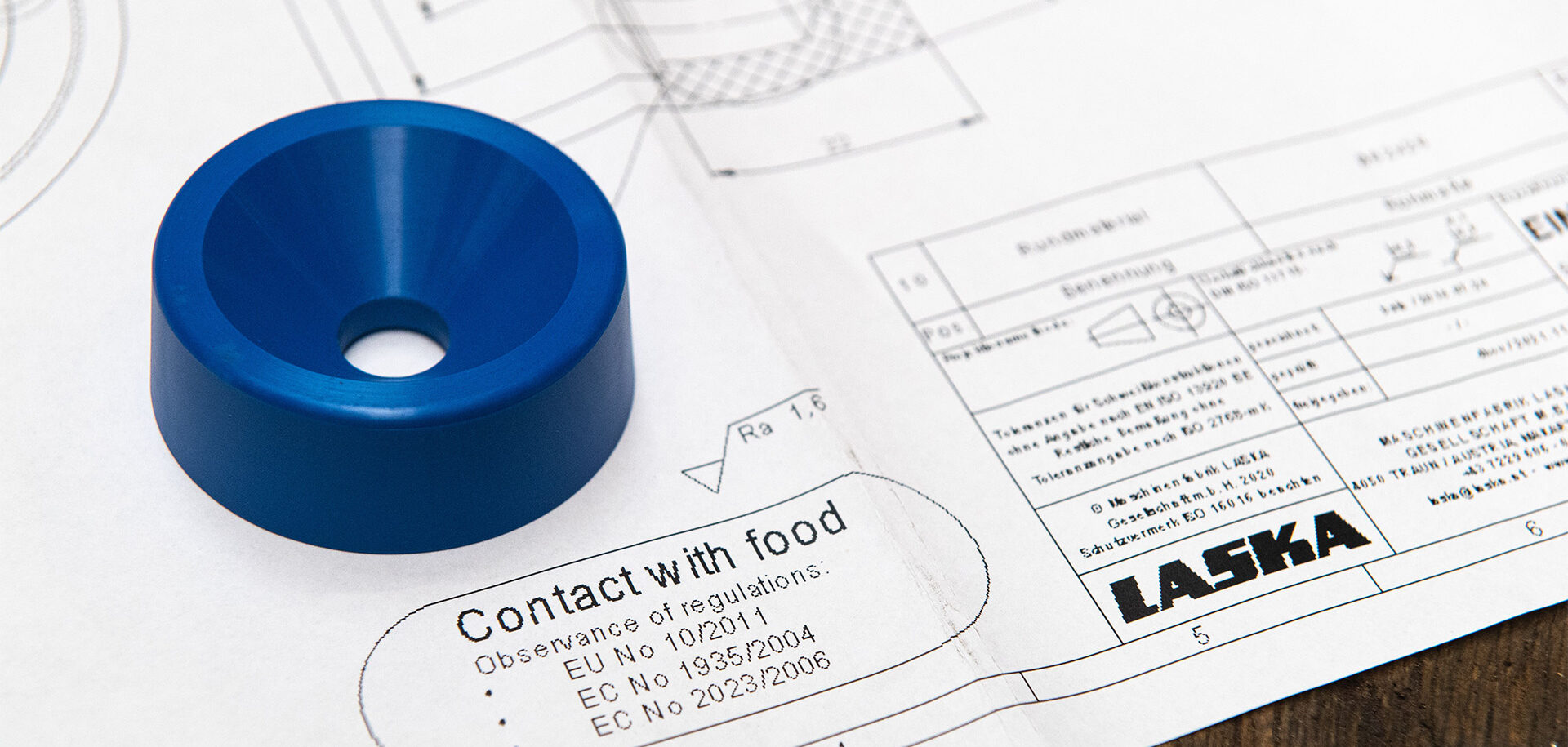

“Seals are a key element in hygienic design,” explains Leibetseder. “You need a sealing solution that performs reliably, with no gaps or dead spots to trap residues; you need a material that is food safe and resistant to cleaning chemicals; and of course you need a blue colour, so any fragments are easily detectable in the event of a seal failure.”

After evaluating multiple material and design options, the Laska team found the sealing solution it was looking for in SKF’s range of specialized thermoplastic elastomer (TPU) seal materials – a polyurethane grade with outstanding chemical resistance, recommended for F&B applications for its detectability.

The material complies with all the major food-industry regulations, including FDA, EU and 3A standards. It is free of animal-derived ingredients and maintains its working properties at temperatures between –20 °C and +110 °C.

SKF’s seal material is also resistant to a full range of common materials used in food processing. In addition to sausage meat – key to its first Laska application – the TPU formulation also handles exposure to dairy products, edible oils, fruits and sugars and alcohol. And to accommodate most common hygiene regimens, H-ECOPUR 95A-blue also resists damage from nitric acid, phosphoric acid, caustic soda, sodium hypochlorite and steam. Finally, as the name suggests, the material is available in the all-important blue colour.

Standardized and custom parts

As well as offering the right performance characteristics, SKF was also able to support Laska with the right manufacturing capabilities. Each of the new grinders uses dozens of seals, and the company required a mix of standard off-the-shelf designs and custom parts produced to its exacting specifications. With its advanced in-house CNC machining capabilities, SKF SEAL JET, SKF could deliver the customised products with short lead times in exactly the volumes Laska needed to meet its product development, testing and production schedule.

The new range of grinders has now been operating with customers for around three years, and the new seals have met all performance expectations. In the meantime, the Laska team has continued its hygienic redesign project, selecting SKF seal solutions for every machine so far. It launched a new emulsifier in 2021 and has just completed the design of its new range of mixing machines.

Other machines are set to follow. “The design cycle for each new machine is around two to three years,” says Leibetseder. “Maybe it is a slow process, but we need to do a lot of testing to ensure that every product we launch meets the exacting expectations of our customers.” And as Laska continues to develop innovative, hygienic solutions for those customers, SKF is supporting it at every turn.

Harsh conditions in food and beverage

Food and drink processing is tough on seals. The equipment used by the sector must endure a range of challenges, including extreme temperatures, high levels of humidity and exposure to abrasive or corrosive materials. Between production shifts, those same machines may be exposed to high-pressure washdowns and caustic or acidic antibacterial cleaning agents.

These conditions are a recipe for failed seals, damaged sealing interfaces and unplanned downtime. If a speck of metal or plastic debris finds its way into the finished product, regulations require producers to recall the entire batch.

SKF has decades of experience in the design and production of seals for the food and beverage industry. Its engineers have worked with equipment manufacturers and operators to solve some of the sector’s toughest sealing challenges. Today, SKF offers a wide range of standardized sealing options for harsh food and beverage applications and has the capability to develop and deliver customized sealing solutions for customers around the world.

Choosing the right design

The starting point for every successful seal design is the selection of the right material or combination of materials for the job. For food and beverage applications, the SKF material offering encompasses three groups of materials.

The company’s thermoplastic elastomer (TPU) seals use high-performance polyurethane materials that combine excellent abrasion and wear resistance, low compression set, high tear strength and outstanding pressure resistance. SKF H-ECOPUR TPU seals are available in the food industry’s preferred blue colour, which enables the optical detection of fragments in the event of seal failure.

SKF’s elastomeric seals are available in a range of high-performance materials that deliver excellent resistance to chemicals and other media. Ethylene propylene diene monomer (EPDM) materials work well when exposed to aqueous solutions, for example, while hydrogenated nitrile rubber (HNBR) and fluoroelastomer (FKM) materials provide good resistance to fats and oils.

The company’s range of thermoplastic sealing materials includes POM, PEEK, PTFE and UHMWPE. These materials may operate with less friction and wear than elastomers, but they require a metal or elastomer component to energize the seal.

All SKF materials used in food and beverage applications are formulated to comply with the requirements of relevant industry regulators, including the US Food and Drug Administration’s list of approved materials and relevant European food safety regulations.