Trouble-shooting at Cummins

Having a product that costs 10 times more than the competing product is not a problem – if you can supply a smart solution.

Summary

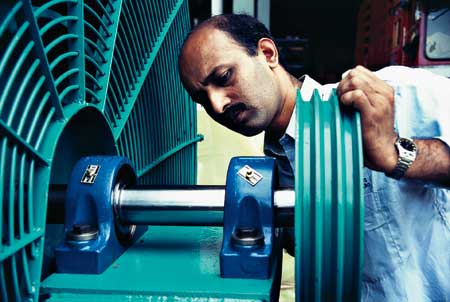

SKF India’s applications team provided a smart solution to the premature failure of bearings in Cummins engines by looking beyond the mere vending of the product. SKF India’s Manish N Mahajan and Gopal A Kamble found that external factors were causing dirt to enter the fan bearings. Apart from improving the sealing of the bearing arrangement to keep out dirt, they found the bearings needed to be upgraded to take the assigned load. “We decided to use SKF ConCentra roller bearing units to add value,” says Mahajan.

Summing up their solution, Kamble says there was increased operational reliability due to the high load-carrying capacity and a good setting of these bearings. Cost savings were possible because of the use of a commercial grade of shaft, time reductions during assembly and simpler logistics. “There was no risk of corrosion in the unit, which can also accommodate misalignment and withstand a dusty environment,” he says. “Standardization of radiator fan bearings was possible for six- to 12-cylinder engines, which until then had different bearings, and this standardization was an innovation in the product. Premature bearing failure was reduced, and Cummins’ image was restored.”

Adds Vilas Bondse, the industrial business unit head of SKF India, “With our sales and application team well informed of the SKF knowledge portfolio and with the customer equipped with engineering competencies and professionalism, the task became easy.”

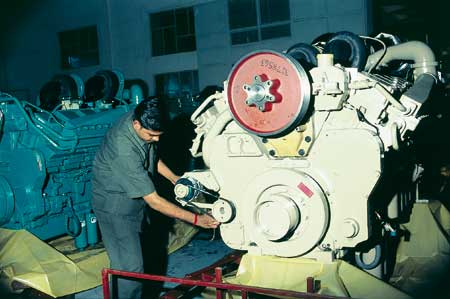

Imagine this scenario. You are an internationally known company selling diesel engines in India, each costing 5 million rupees (EUR 88,000). The radiator fan, needed to cool the engine, is equipped with ball bearings, costing a paltry 2,000 rupees (EUR 35). But the bearings fail frequently, the engine overheats and seizes, and you have a very unhappy customer on your hands.

This was happening to Cummins India Ltd. (CIL), a 51 percent subsidiary of Cummins Inc USA, the world’s largest diesel engine designer and manufacturer of engines larger than 200 horsepower. CIL is India’s largest producer of engines in the higher horsepower range.

Manish S Save is senior manager for applications at CIL’s headquarters in Pune, about 180 kilometres from Mumbai. He recalls the complaint of one such unsatisfied customer. A fan bearing failed, the cooling fan blocked and hit the radiator, damaging the core, and water leaked, causing the seizure of an overheated engine. “This was a catastrophic failure that required a major repair at a rather high cost,” he says. “To make matters worse, this engine was out of warranty, so the customer was angry, and he made sure his complaint reached the topmost level in CIL. Of course, as a goodwill gesture, we immediately extended the warranty.”

With a few more complaints of engine failure coming in, all due to premature bearing failure, it was time for Save’s application team to find a solution to the problem. A small, relatively cheap component was putting an entire engine in jeopardy. The team turned to SKF India Ltd.

CIL makes about 10,000 diesel engines a year (60 hp to 2,700 hp) in India, and these are used in some 450 applications. The company’s turnover in 2003 was 9,420 million rupees (EUR 166 million). “In our engines, used for generator drives, we had a common housing where we assembled two bearings and a shaft with a fan on one end and a drive pulley on the other,” says Save. “But this was a very tedious and long process. So within CIL we thought of introducing something new.”

At SKF India, Manish N Mahajan, area sales manager for the western region, and his colleague, Gopal A Kamble, manager for application engineering, swung into action to find a solution for their client. Mahajan explains that while analyzing the problem, the SKF team found that the bearings, supplied by a competitor, had a life of only 8,000 hours. The failure was happening in engines used as diesel generators in continuous operation in power plants. And the power plants where the diesel generator sets were used were situated in open spaces where there was ongoing construction activity. Dirt was contaminating the bearings. Dirt was also an issue when the engines were used in applications such as mines where dust and grime are ubiquitous.

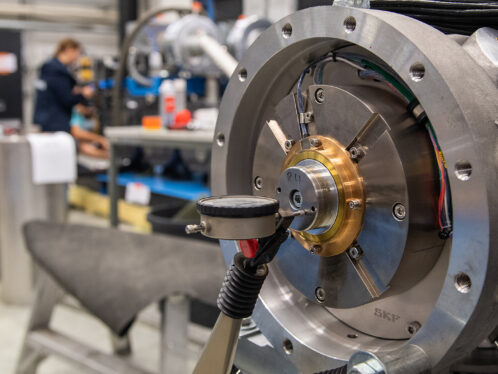

SKF India proposed to improve the bearing arrangement by incorporating a better sealing to keep out dirt and to upgrade the bearings to cope with the load. SKF India proposed using ConCentra roller bearing units to provide 50,000 working hours compared with the previous 8,000 hours. But the price, at 20,000 rupees (EUR 350), was tenfold more.

Keeping in mind the important business potential from a customer such as CIL, detailed technical discussions were held with CIL and its end users. Price was not discussed. “By drastically cutting down price, anybody can get customers,” says Mahajan. “But we didn’t do that. We said ‘Our products are costlier, but they offer higher quality and [a longer] lifespan. More important, we don’t sell products, we sell complete solutions, and this is both an opportunity and a challenge for us.’”

The SKF team also had to find a solution to the fact that Cummins Inc uses the imperial system and CIL uses the metric system. Kamble’s team fine-tuned the difference between the two systems and zeroed in on a size that would work. Within six months the team had approved samples of the bearing unit and had them mounted as a prototype with CIL’s customer. The test run was successful, and value was added in both performance and easier mounting and dismounting.

“We saw the customer not merely as a vendor but as a partner, and that is a paradigm shift,” says Mahajan.

But at the CIL end, it was not smooth sailing. The commercial and marketing teams resisted the solution because of the cost increase. India is a competitive and price-sensitive market. “They were up in arms,” says Save, “but the customers who made the complaints are very important, and the technical team convinced them we had to change.”

The full-fledged operations with SKF bearings started in February 2004. “I doubt we’ll get any more complaints on the bearings front,” Save says. He is particularly pleased with the quick response from the SKF technical team. “Once we sent the applications questionnaire, the turnaround time was only two or three days – a week at the most.”

Kamble says CIL customers should be happy because diesel generator sets are used in periods of crisis as a backup system for the power supply to keep the production running. “But if your backup is not reliable, then it’s a big loss,” he says. “Our objective is to give confidence to the end customer that a Cummins engine, once switched on, is trouble-free and works smoothly.” In areas where the diesel generator sets are used as the primary power supply, a trouble-free operation is even more crucial.

Adds Mahajan, “This year the business from Cummins in this product alone will be around five million rupees (EUR 88,000), and it is likely to increase to eight to nine million rupees (about EUR 150,000) next year. We see this partnership only growing.”

On CIL’s operations and future plans, Save says 50 to 60 percent of its engines go to the diesel-generator-set market and the remainder go to other applications, such as marine, locomotives, compressors, construction and mining, fire pumps, oilfields and so on. “We are into every single application where a diesel engine can be used, and we export engines to African and Southeast Asian countries,” he says. “We also export engines back to Cummins Inc. We are the only Cummins subsidiary in the world manufacturing V-28 and K-38 models. Soon we will also be the sole manufacturers for the K-50 model, and we export all these to the parent company. We are getting more orders than we can execute, and we are completely sold out of V-28 engines for two years.”