CARB – three bearings in one

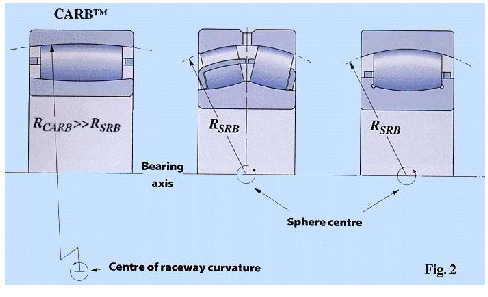

The rollers have a convex profile which is considerably flatter than that of a spherical roller bearing (fig. 2). The rings are shaped with essentially the same curvature as the roller, and there are no guiding flanges (fig. 3). This design permits both large axial displacement and misalignment. The rollers are long, which gives the bearing high radial load carrying capacity.

Customer demands for a space saving and robust bearing with low friction, resulted in CARBTM, a new type of bearing, which permits both large axial displacement

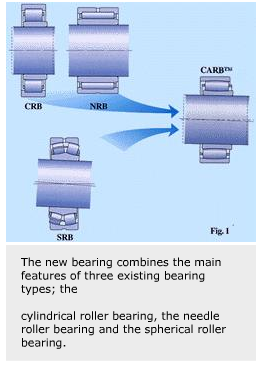

and misalignment.CARBTM stands for Compact Aligning Roller Bearing, a new bearing type developed and patented by SKF. The new bearing combines the main features of three existing bearing types (fig.1):

- Cylindrical roller bearing (CRB):axial displacement within the bearing.

- Needle roller bearing (NRB):as cylindrical roller bearing but also with low section height.

- Spherical roller bearing (SRB):high radial capacity and ability to accommodate misalignment.

The rollers have a convex profile which is considerably flatter than that of a spherical roller bearing (fig. 2). The rings are shaped with essentially the same curvature as the roller, and there are no guiding flanges (fig. 3). This design permits both large axial displacement and misalignment. The rollers are long, which gives the bearing high radial load carrying capacity.

Bearing characteristics

Axial displacement

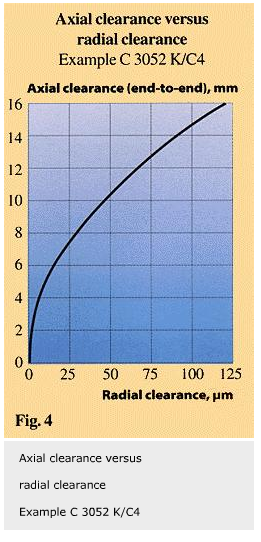

When one ring is displaced axially, the roller is displaced by half as much, and the bearing clearance is reduced very slightly. A typical relation between radial and axial clearance is shown in figure 4. For a typical operating clearance, the axial clearance is as much as 10 % of the bearing width and some displacement is even possible beyond this limit without life reduction. This is more than sufficient for most applications.

Misalignment

When a rotating bearing is misaligned, the rollers make very small adjusting movements. For normally occurring misalignment angles, that is below 0.5 °. These adjusting movements have little influence on life and friction.

Load carrying capacity

The load carrying capacity, expressed as the basic load rating given in bearing catalogues, is often used as a basis for selection of type and size of bearing. However, the ability of the bearing to carry load and still reach the expected life can be reduced if there is misalignment.

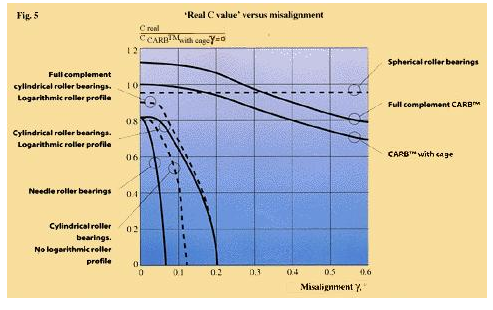

Figure 5 gives the general picture of how ‘real carrying capacity’ varies with misalignment for some common roller bearings. Because CARBTM has self-adjusting rollers, the bearing can be considerably misaligned before stresses increase.

Downsizing can be illustrated by this diagram: if the misalignment is greater than 0.1 °, a CARBTM with only 70 % of the capacity of the best cylindrical roller bearing would still have a longer life. This is equivalent to CARBTMbeing two sizes smaller with the weight of the bearing alone reduced by 40 %. Alternatively, if the shaft diameter size has to be maintained, the section height (the bearing outer radius minus the bore radius) can be halved.

Friction

The flattened roller profile, in combination with good roller guidance, explains the CARBTM design’s low friction. The friction is up to three times lower than that of single row spherical bearings and is typically as low as the friction of double row spherical roller bearings and cylindrical roller bearings.

The self adjustment of the roller in a misaligned CARBTMcauses some additional sliding. Friction therefore increases marginally with misalignment. Even for such a great misalignment angle as 0.5 °, the increase is typically less than 20 %.

Tests

In order to benchmark the new bearing type and to find its limits, different bearing executions and test conditions have been analysed:

- heavy loads up to C/P=2

- high speed up to 20,000 r/min

- axial displacement up to 10 mm

- misalignment up to 1 °

- with and without cage

- with and without seals

Tests have been done both in SKF and customer laboratories. The bearings were then field tested in real applications including continuous casters, automotive gearboxes and paper making machines.

CARBTM in paper making

In a paper making machine the paper is dried by a large number of fast rotating steel cylinders.

These cylinders are up to 10 m long, 2 m in diameter and are heated by steam of up to 200 °C.

The long cylinders ‘grow’ axially from thermal expansion by some 10 mm and, depending on alignment accuracy and deflection, the misalignment between cylinder and bearing housing can be up to 0.5 °.

Today there are different ways of allowing the bearing arrangement to move axially through 10 mm and at the same time compensate for misalignment, but all these solutions have drawbacks. For good misalignment capability, for example, some stability is sacrificed, while to gain sufficient axial movement within the bearing, the ability to safely take up misalignment is sacrificed.

To improve these problems, the CARBTM design has been proposed as the bearing for the non-locating side in the dryer section of paper making machines. Since the beginning of 1994 an increasing number of CARBTM units have been running in these machines following successful laboratory and field tests.

The results are very promising. Not only has the bearing arrangement been made simpler for the customer, but a lot better.

The thermal expansion and the misalignment of the cylinders are taken up inside the CARBTMwhich is mounted in a housing bolted to the foundation.

Magnus Kellström and Peter Åqvist,

SKF Spherical Roller Bearing Division,

Gothenburg, Sweden