Lubrication of bearings at low temperatures

About 80 percent of all bearings are grease-lubricated, Grease is a two-phase lubricant, containing base oil (about 80-90 percent) and a thickener. There will also be additives such as anti-corrosion agents, anti-wear and anti-weld (so called extreme pressure, or EP) additives. To provide adequate lubrication, the base oil and thickener must be allowed to flow to the bearing raceways. When base oil viscosity is high, for example due to low temperature, base oil cannot separate out of the thickener matrix. This is referred to as the grease having a low base oil separation rate. Because of this low separation rate, the availability of lubricant in the raceway-roller area is small, and the risk for starvation becomes high. If the additives cannot be re-fed to the surface, roller skid becomes even more dangerous, because there are no additives to protect the skidding surfaces. Therefore, a highly viscous oil, either pure or as base oil in a grease, will give rise to high friction in a rolling bearing, and increase the risk of bearing damage. This is true at low temperatures but also under other conditions where high viscosity has been selected. Obviously, the statement of “lower viscosity, better surface separation” is contradictory to the common belief that higher viscosity is better, but it is nevertheless true. In recent years, SKF has studied lubricant starvation and conditions when it occurs, and has concluded that there is an optimum base oil viscosity for every bearing. Too high and the roller-raceway contacts starve and frictional losses go up. Too low and the separating film becomes so thin that surface irregularities touch, increasing friction. In both cases, the consequence is identical: wear and premature failure. To conclude, one has to keep a few simple things in mind when selecting bearing lubricant for low temperature use.

Summary

Like humans, bearings suffer terribly in the cold if they are not cared for properly. As the harshness of a cold climate does not preclude human habitation, machines are also expected to keep operating when the thermometer drops.

Understanding what happens to the bearing system, including lubrication, is at the heart of keeping all moving machines thriving in chilly environments. SKF worked closely with companies that need to keep their businesses running despite the weather. It discovered that choosing the right type of lubrication could overcome most of the difficulties of working in the cold. The experience gained from this study is now being used to help other customers with similar problems around the world.

In low-temperature conditions, lubrication media must be carefully selected, taking into account the whole range of temperatures over which machinery has to function.Human activity has spread around the globe to the extent that it is possible to live and work virtually anywhere, regardless of climate. In places like Scandinavia, Alaska and northern Russia, temperatures often remain below freezing for weeks or months. Despite the inhospitable environment, inhabitants of these areas expect that cars, buses and trains will run even in the depths of winter.

People in the colder climes should be able to expect machinery lifetimes similar to those of people living further south, barring unforeseen breakdowns. But many designers are unaware of the problems that arise as temperatures fall. Rolling bearings are some of the more difficult mechanical components to design for reliable operation over a wide temperature range.

Operating machinery in low temperatures poses some unique problems. The proper choice of lubricants can ensure reliable operation over a wide temperature range. Though northern countries may experience extremely cold winters, summer temperatures can be pleasantly warm.

Conditions in cold climates

The Swedish iron ore company LKAB has a large harbour complex for loading ore onto ships in the northern town of Luleå. Ambient temperatures are often below –20 °C during the winter months, and days when the temperature hovers between –30 and –40 °C are not unusual. As long ago as 1988, LKAB had identified problems in loading equipment and vehicles that included high frictional losses in gearboxes, material brittleness at low temperatures, and all kinds of starting problems. These problems were often related to rolling element bearings, and more specifically to the lubricant – grease or oil – inside the bearing. At that time, no reliable remedy existed and the recommended solution was to close the harbour when temperatures fell too low.

Transport company MTAB experienced similar problems. This company moves ore by rail from the mines at Kiruna in northern Sweden to harbours in Norway and steel works in Sweden. The company’s heavy goods trains run 24 hours a day, seven days a week, even during the winter. At low temperatures, MTAB reported train wheels sliding along the rails – the powerful locomotive was dragging rail cars whose wheel bearings were frozen stiff.

During the winters of 1990 to 1995, several trains derailed, resulting in high rescue costs, major cleanups and shutdowns of the transport system. Due to severe bearing damage after derailments, the problem could never be traced to a single cause. Consequently, MTAB contacted SKF and Luleå University to find a solution. After an extensive investigation, the cause was determined to be lubricant related.

Since SKF operates with close collaboration between sales, application engineering, product development and R&D, it could offer the MTAB the type of support that would be difficult to find elsewhere. SKF provided new spherical roller bearings and specially designed axleboxes equipped with grease sample plugs. These were fitted on five instrumented ore cars running between Kiruna and Narvik. After combined laboratory and field testing and analysis of existing grease and commercially available alternatives, the wheel bearing grease was eventually changed. SKF gained valuable experience from this project, which it is applying to other applications throughout the colder parts of the world.

Causing damage

Most bearings will start to rotate eventually, even at –25 °C, if the engine or actuator driving them is powerful enough. In the MTAB train, the bearings were originally filled with grease designated for operation over a medium temperature range (–20 °C to +100 °C). As the locomotive starts to pull the wagons, the wheels may rotate intermittently or with extremely high friction. Heat is generated in the bearings, and the grease becomes heated as well. Now the bearings will indeed rotate. This heating-up process takes 60 seconds or less, still enough time to cause severe and irreversible damage to the bearings.

Most people know that olive oil kept in the refrigerator at +8 °C becomes solid and must be warmed to room temperature before it can be poured out of the bottle. The same happens to any engine or gear oil, but usually at a lower temperature than +8 °C. Oils are classified by pour point, defined by a standard test in which oil is poured out of a thin pipe. The lowest temperature at which it can still flow out of the pipe within a specified time is designated the pour point to oil. The pour point is related to the oil viscosity, or flowability. When the temperature falls, viscosity increases and flow becomes more difficult. Unfortunately, flow in a thin pipe is not very useful in determining lubricant behaviour in a bearing.

Another measure commonly used to describe oil behaviour at low temperature is the viscosity index, or VI. Here, misunderstandings are frequent. One has to be careful when looking at the VI of an oil, because it cannot be used as a single measure of low temperature performance. VI describes how viscosity varies with temperature. High VI implies low variation of viscosity with temperature. Low VI means that viscosity variation with temperature is high. High VI oils include esters, polyalphaolefines (PAO) and silicone oils. Mineral oils are often low VI oils. It should be noted that VI says nothing about the actual base oil viscosity at low temperature.

For greases, a way to assess low temperature behaviour is to measure the friction torque of a small ball bearing packed with grease and rotated at 1 r/min at a set (low) temperature. This method is standardised and used worldwide. However, it is well known that the degree to which the bearing is filled strongly influences friction torque, and in reality not many bearings are 100 percent filled. Bearing friction is related to the shear stresses that occur in the lubricant during rotation. These stresses will not be the same in a small ball bearing as in a large spherical roller bearing. Consequently, this test is also not reliable on its own for the assessment of low-temperature lubrication.

Unfortunately, there is no universal method to predict low temperature performance of lubricants in a bearing. This is why MTAB’s situation required a field test, which generated information on which laboratory test methods are the most useful. A “normal” grease consumer will not have access to such a wealth of data but can keep in mind some simple guidelines. Generally, bearing lubricants should not have excessively high base oil viscosity.

The consequences of excessive viscosity in a rolling element bearing are:

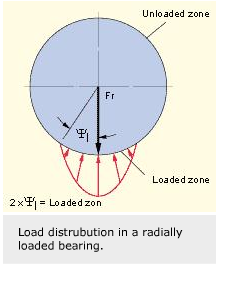

- An increase in friction due to the additional effort required to move thick oil away from moving rollers. These losses are called churning losses and contribute strongly to overall bearing friction. If the churning losses are very high, rollers can slide instead of roll. This is called roller skidding and occurs in the unloaded zone or at the entry to the loaded zone in a radially loaded bearing. Skidding can cause flat spots on the rolling elements, which later lead to premature bearing failure.

- Bearing friction will increase due to increasing cage-rolling element friction, which is strongly related to oil viscosity. Cage-roller friction contributes to roller skid.

- Once the oil on a raceway has been pushed aside by a passing roller, it does not easily flow back again. Hence, the next roller will contact less oil, and the third might not even contact enough oil to provide surface separation. This lubrication situation is commonly called starved lubrication. If the rollers are moving at high speed, starvation appears earlier, because time for reflow between each passing roller is shorter. Starvation can lead to surface damage.

About 80 percent of all bearings are grease-lubricated, Grease is a two-phase lubricant, containing base oil (about 80-90 percent) and a thickener. There will also be additives such as anti-corrosion agents, anti-wear and anti-weld (so called extreme pressure, or EP) additives. To provide adequate lubrication, the base oil and thickener must be allowed to flow to the bearing raceways. When base oil viscosity is high, for example due to low temperature, base oil cannot separate out of the thickener matrix. This is referred to as the grease having a low base oil separation rate. Because of this low separation rate, the availability of lubricant in the raceway-roller area is small, and the risk for starvation becomes high. If the additives cannot be re-fed to the surface, roller skid becomes even more dangerous, because there are no additives to protect the skidding surfaces. Therefore, a highly viscous oil, either pure or as base oil in a grease, will give rise to high friction in a rolling bearing, and increase the risk of bearing damage. This is true at low temperatures but also under other conditions where high viscosity has been selected. Obviously, the statement of “lower viscosity, better surface separation” is contradictory to the common belief that higher viscosity is better, but it is nevertheless true. In recent years, SKF has studied lubricant starvation and conditions when it occurs, and has concluded that there is an optimum base oil viscosity for every bearing. Too high and the roller-raceway contacts starve and frictional losses go up. Too low and the separating film becomes so thin that surface irregularities touch, increasing friction. In both cases, the consequence is identical: wear and premature failure. To conclude, one has to keep a few simple things in mind when selecting bearing lubricant for low temperature use.

The base oil should have:

- a high viscosity index (VI). For engine oils this implies SAE grade 5W/40 or 5W/50.

- a low pour point.

- as low a base oil viscosity as possible at the required operating temperature.

These requirements usually imply synthetic base oil such as ester, PAO or a mix of these two. Additionally, all other requirements such as correct consistency and sufficient relubrication intervals will have to be fulfilled. Grease selection, like many other choices in life, is a compromise.

In the case of the wheel bearings on MTAB’s iron ore cars, the previous grease was based on a mineral oil and had a low base oil separation. At low temperatures, this could be seen as creating very high bearing friction torque at start-up. The grease also became soft under vibrations, which made it flow back in large quantities as soon as the train stopped. The low ambient temperature made the thick and soft grease freeze, and every time the train was started, frozen grease had to be removed by the rollers. The consequence was high start-up friction, possible bearing damage, and severe leakage through the labyrinth seals once the train was running. The new recommendation for MTAB’s axlebox bearings, therefore, is a grease with a high VI base oil, 50 percent reduction in base oil viscosity, the highest possible base oil separation rate and high mechanical stability. Since the grease change, no derailments have occurred. Moreover, SKF has recently received an order for taper roller bearing units for the new Malmbanan iron ore carriages. These bearings will be lubricated with a different low-temperature grease suitable for taper roller bearings, but the selection criteria have been the same.

Victoria Wikström, AB SKF, Göteborg, Sweden