A new performance class for angular contact ball bearings

SKF has developed a new performance class for standard angular contact ball bearings – the SKF Explorer series. The series is now being launched in Europe. Implementation in the Americas and Asia will take place in the third quarter of 2002.

Summary

A new performance class is set with the SKF Explorer range of angular contact ball bearings. The possibility of increased power density, longer bearing life and higher bearing reliability opens up a new world of machine design options. Because of the important improvements inherent in SKF Explorer angular contact ball bearings, new bearing life calculations are applied.

SKF Explorer series angular contact ball bearings, both single row and double row, may look like others of their kind, but they perform to a higher level. To achieve this enhanced performance, SKF researchers re-engineered each component at the macro and micro level. The result is bearings that are running smoother, cooler and longer.

Material and heat treatment

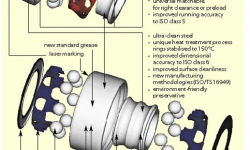

The material cleanliness, or metallurgical quality, is characterised by its macro and micro non-metallic inclusions, the levels of titanium nitro carbides and/or by the total oxygen content. SKF researchers have established a correlation between oxygen content and rolling contact fatigue strength. Therefore, SKF Explorer series angular contact ball bearings use only the cleanest available steel, 100 % degassing and the lowest oxygen contents (5 ppm on average). The use of cleaner bearing steel and the manufacturing technology of ring blanks (cold rolling, forging) together lead to longer rolling contact fatigue life.

A unique heat treatment process gives the SKF Explorer series angular contact ball bearing (ACBB) material the utmost dimensional stability, in addition to the correct hardness and the related wear resistance. The dimensional stability is based on a minimum content of retained austenite, and the heat stabilisation is designed for temperatures up to 150 °C. This is essential to keep the bearing clearance or preload constant.

Improved accuracy

An improved dimensional accuracy (ISO class P6 instead of normal) gives a lower spread in bearing fits and thus less influence to changes of the bearing internal clearance or preload. The improved running accuracy of SKF Explorer series ACBBs (ISO class P5 for single row and P6 for double row) means that the bearings will be mounted more accurately and that they will more effectively locate the shaft axially and radially during operation. This increases the guiding quality of the bearings, reduces vibrations, wobble and friction, decreases seal wear of external seals and increases the overall service life of the bearings and other components.

Upgraded balls contribute to the improved running accuracy. The reduced waviness of the balls has a significant impact on vibration and bearing noise.

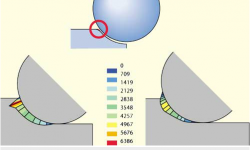

The ground, special harmonic shape of the transition of ring raceways to the bearing shoulder, together with the improved surface finish, lowers the contact stresses. It also reduces edge stresses and makes the SKF Explorer series ACBB capable of carrying increased thrust loads and avoiding ellipse truncation.

Improvements to the cage include a redesigned ball pocket and improved surface finish. The redesigned cage adds additional strength while maximising the effects of the lubricant, enabling the SKF Explorer bearing to run 3 to 5 °C cooler than regular bearings. Single row angular contact ball bearings are available with either a strengthened glass fibre reinforced polyamide (PA) 6.6 cage or a machined solid brass cage with improved tolerances. Double row angular contact ball bearing cages are available with either the well-known glass fibre reinforced PA 6.6 snap-type cage or a newly developed pressed and hardened steel cage, the “crown cage.”

Universal matching

The SKF concept of universally matchable single row ACBBs with clearance classes CB, CA and CC and the preload classes GA, GB and GC is unchanged. Bearings can be mounted back-to-back or face-to-face, and the necessary clearance or preload will be achieved. Coupled with the new heat treatment, the SKF Explorer series ACBBs guarantee almost no change of the initial preload or clearance.

Tests have been made to check the change of the clearance (CB) and preload (GA) with time (10,000 hours) and temperature (110 °C). For the unique SKF Explorer heat treatment (S0) the clearance remains as clearance (on average), while a normal heat treatment (SN) would give preload. For the preload case (GA) S0 keeps the preload constant and gives 100 % bearing life; a normal heat treatment (SN) would result in a very high preload and reduced bearing life.

Other

All SKF Explorer series ACBBs are produced under very clean conditions, since that affects the service life and quiet running performance of the bearings. Other features of the SKF Explorer series include new preservatives, new greases, new shields, new laser marking for better traceability, new manufacturing methodologies and total quality management according to ISO/TS 16949. These aspects, together with the improvements mentioned in this article, contribute to the new performance class the series has achieved.

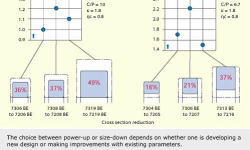

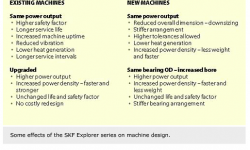

SKF Explorer series ACBBs can be used in many ways. One could take advantage of the on average three times longer service life, or one could aim for downsizing.

SKF Explorer series ACBBs will not only reduce noise, vibration and warranty costs but will also build value into each component by increasing speed, improving service life, reducing heat and power consumption and controlling maintenance costs. The choice between power-up or size-down will depend on whether one is developing a new design or making improvements within existing parameters.

Hubert Köttritsch,

SKF Österreich AG, Steyr, Austria