Summary

Increasingly, bearing users are looking for improved locking systems that permit easy use, yet are reliable. SKF has launched the ConCentra concept, a series of locking products that are designed to fulfil customers’ desires to improve reliability and serviceability. It does this by moving away from traditional mounting solutions that require shaft setscrews, eccentric locking collars, adapter sleeve mountings and keyways.

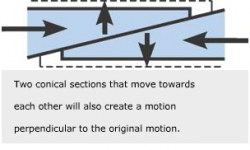

It is well established that two conical sections will, when moved relative to each other, have an additional radial displacement. By adapting this basic principle, SKF engineers have developed a slim locking system that overcomes many disadvantages of current locking systems.

ConCentra is intended to meet the growing trend for making complete bearing concepts available from one supplier. With a locking solution such as ConCentra, SKF can offer not only its competence in bearings but also locking solutions for bearings, sprockets and pulleys.

Following successful testing and customer trials, SKF has launched the ConCentra locking system. The aim is to offer a locking solution that offers more effective locking with lower vibration and less fretting corrosion.ConCentra has been conceived to meet the increasing demand for concentric locking with a design that is both simple and reliable in operation. A reliable and easy mounting solution for bearings is a key issue for SKF customers. The new ConCentra concept is designed to fulfil customers’ desires to move away from traditional mounting solutions that require shaft setscrews, eccentric locking collars or adapter sleeve mounting.

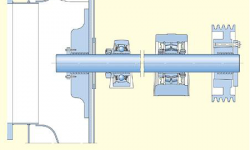

The Concentra locking system has been incorporated into ball and roller bearing units, as well as in bushings for power transmission components. In particular, ConCentra could be of benefit in applications such as fans used in air handling, in materials handling and in industrial laundry equipment where there are difficult environments.

Simple concept

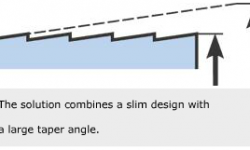

SKF ConCentra is based on the fact that two conical sections will, under a horizontal movement, have an additional perpendicular displacement. This is a well-understood mechanical principle that is applied in systems throughout industry. For ConCentra, this principle has undergone considerable refinement. Although two rings with conical sections will move in the radial direction during an axial movement, the ability to use this as a locking mechanism for bearings and power transmission components requires a very thin cross-section design. Traditionally a very thin cross-section would mean the use of a small taper angle. However, designs with small taper angles have important drawbacks. One is the considerable amount of axial movement required to obtain the desired radial displacement and subsequent locking force. Another is the difficulty of dismounting the system because of the self-locking effect of the shallow contact angle of the two steel rings, having a friction coefficient of m = 0.15. To avoid this, a taper angle larger than 8.5 degrees is desirable.

SKF engineers had to address the question whether it was possible to combine a slim design with a large taper angle in sizes encountered in bearing and bushing widths. The answer was to adapt the profile of the conical sections into a series of shorter cones. The result is the SKF-patented multi-taper design where each taper has the same steep angle.

Complete system

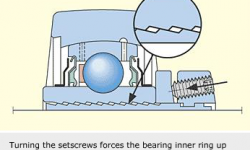

Having established the basic design concept, the step to a complete locking system was relatively straightforward. Three components are required to create a complete locking system. These are two sleeves, one inner sleeve with the cone profile on the outside and one outer sleeve with the same cone profile on the inside, and a mechanism to displace the two sleeves relative to each other. To allow the necessary radial expansion when tightening the setscrews, one or both sleeves are split. The illustration above shows the locking system incorporated into a bearing where the set screws are used to force the bearing inner ring (with the multi-tapered surface machined into the bore) up the inclined planes of the inner sleeve to provide a tight, concentric fit on the shaft.

The advantages of the SKF ConCentra system, compared with traditional locking methods with shaft setscrews or eccentric locking, are manifold. The new technology provides a high locking force even for commercial grade shafts with a diameter tolerance of h9-h10. This eliminates the need for any grinding and polishing of shafts to precision tolerances, as typically required for power transmission components and bearings with traditional locking methods of setscrews or eccentric locking collars. Also, for power transmission components, the ConCentra system eliminates the need for costly keyways, while also enabling the use of hollow shafts when appropriate in an application.

The true concentric mounting offered by ConCentra ensures that the locking force is distributed symmetrically under the loaded area. This not only eliminates the damage to the shaft from setscrews, but also allows bearing applications to run faster and with less vibration. The nearly 360-degree interference fit with the shaft reduces fretting corrosion that can result from micro movement between shaft and bearing inner rings or bushings when using traditional designs. The system permits easy mounting and dismounting. The Allen key for mounting is provided with the unit and comes with a built-in torque indicator. When the screws are tightened to the correct torque, the bearing or bushing is mounted concentrically with the correct contact force.

SKF ConCentra is applicable in new applications as well as a replacement for existing locking systems. It is possible to replace almost any existing type of locking system, including those that use shaft set screws and shaft keys, with a new product from the SKF ConCentra series. As the mechanical unit will distribute the locking force equally over the contact surface, the contact pressure will be quite low. Tests have proven that the low and equally distributed contact pressure eliminates the risk of local material failure in the inner sleeve, even if the system is mounted over an old keyway.

Future trends

The trend for the future is that more and more customers want to buy a complete bearing concept from one supplier. With a locking solution such as SKF ConCentra, SKF will be able to offer this service to customers. SKF can offer not only its competence in bearings but also locking solutions for bearings, sprockets and pulleys. This technology opens up a new world of possibilities for SKF to meet increasingly challenging customer requirements.

Magnus Hultén

Development Centre, SKF Industrial Division, Katrineholm, Sweden