Summary

Lubricated by mud

Under normal industrial conditions, bearings perform in a clean, lubricated environment, and they can be used virtually forever. But Baker Hughes Inteq’s mud-driven Navi-Drill™ motor does not enjoy what could be called a “normal” environment.

Its exposed bearings, which are located just above the drill bit, are subject to harsh downhole conditions, including water, grit, rock, high temperatures and high pressure.

Hubert Köttritsch, manager of the development centre for SKF Österreich AG, says the main causes for bearing failure under such critical conditions are corrosion, wear and fracture from heavy-duty use. So SKF builds for the Navi-Drill an exclusive stack of bearings that utilise a full complement angular contact thrust ball bearing. The rings and the balls are made of special steel and they undergo special heat treatment.

SKF has cooperated on the development of Navi-Drill bearings for 20 years and it continually works to improve their baseline performance. More recently, SKF has also started improving motor bearings for Drilex, the product sales company of Baker Hughes Inteq.

Köttritsch says SKF wants to optimise the characteristics of the bearings through material, hardness, the use of special coatings, macro and micro-geometry and load distribution. The process is continuous; SKF performs the testing at its Austrian facilities.

High-tech drilling systems from U.S.-based Baker Hughes Inc. can be the difference between make or break in oil exploration. German group member Inteq has a vital role in product development.In the increasingly competitive and ever-changing global oil and gas industry, technology plays a critical role. Energy companies seek greater efficiency and an increased return on their investments in exploration and extraction. They want to reduce costs, but they also want to increase their reserves and boost production.

Baker Hughes Inteq – with its three technical disciplines of drilling, evaluation and drilling fluids – strives to meet these challenges. It has a full range of technology and services that make it possible for customers to more accurately place wells in reservoirs and that allow more efficient drilling and evaluation of formations next to the well.

The company’s integrated products and solutions include directional drilling and Measurement-While-Drilling systems, drilling fluid systems, surface logging services, coring and subsurface surveying.

Inteq, which stands for Integrated Solutions and Quality, is part of Baker Hughes Incorporated, a Fortune 500 organisation based in Houston, Texas. The engineering expertise for Inteq’s systems and services can be found jointly at corporate development centres in Houston and in Celle, Germany. Baker Hughes also has a test rig in Mounds, Oklahoma, in the U.S.

Using mud for propulsion

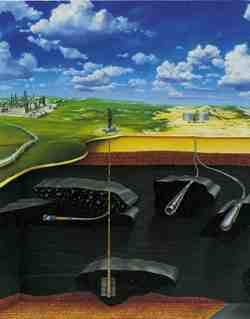

A prime example of Inteq’s innovation is the Navi-Drill™ motor, or what engineers call the “bread and butter” of the company. The Navi-Drill uses the hydraulic force of a drilling fluid instead of the rotation of the drill string to propel the drill bit.

The drilling fluid – a special type of water-, synthetic- or oil-based mud – is pressurised to about 5,800 pounds per square inch (40 MPa) and pumped through the downhole drill string. After the fluid passes the motor and the drill head, it is pushed outside the drill tube and back towards the surface. Along the way, it reinforces the wall of the hole and collects grit and rock particles, large chunks of which are filtered from the mud before it is again pumped down into the hole.

Inteq has been so pleased with the Navi-Drill that it has developed a new generation, the Navi-Drill Ultra Series motors. These motors are built to deliver more power and faster penetration rates, and have a longer operating life.

Directional drilling breakthrough

Another recent Inteq innovation is the AutoTrak™ Rotary Closed Loop Drilling System, a completely self-sufficient downhole tool.

AutoTrak drills continuously in the rotary mode and has a downhole guidance system that automatically steers the drill head along a pre-programmed course. Steering is controlled by a non-rotating, orienting sleeve that has expanding stabiliser pads. Precisely controlled force on these pads allows the tool to maintain its inclination alignment and direction in the well path. Course corrections are made continuously during drilling operations, and real-time monitoring on the surface permits changes to the well path programme if desired.

AutoTrak was developed jointly with Italian oil company Agip S.p.A. at Inteq facilities in Celle. It delivers higher penetration rates compared with conventional drilling systems. It also enables drilling at extended distances (currently up to 10 kilometres) because it drills a smoother wellbore with less total friction on the drilling assembly than conventional systems.

Because it can cost 15 to 20 million U.S. dollars today just to drill one hole, the AutoTrak system can help reduce exploration costs. A rig with this equipment can cover a larger area by drilling from a central point in several directions, like a star, saving the customer from costly location-to-location rig moves or even from building additional offshore platforms. With AutoTrak, it is also possible to use a less costly onshore drill rig to reach offshore reservoirs that are situated near a coastline.

Total Oil Marine, a member of the French Total group, and Inteq proved the value of AutoTrak technology in February 1998, when the system was used to successfully complete Total’s 3/9a-N37 well in the Alwyn North field, 160 kilometres northeast of the Shetland Islands off Scotland. The automated system guided the well to intersect two separate targets without interrupting drill string rotation. And it drilled more than 1,000 metres in 137 hours of failure-free operation.

Laurent Parra, who heads drilling engineering at Total, says steering while drilling in the rotary mode – which in this case reduced drilling time by about 64 hours – represents “one of the biggest steps forward” in directional drilling technology. “This type of tool will allow us to access new reserves with much lower drilling costs,” he says.

Baker Hughes sells some equipment to end users. But because the cost to buy and maintain drilling tools is so high, it also rents equipment, along with its expertise and service, to the customer. This means that Baker Hughes engineers are physically present on a rig, making decisions throughout the life of a project. This simpler, one-stop service for customers is an approach that is well-suited to the streamlined petroleum industry of the 1990s.

Baker Hughes’ extensive global infrastructure allows it to benefit from increased exploration, development and production activity in key regional markets. The company employs 20,000 people worldwide and has regional offices in 45 countries.

Digging up new opportunities

Last year saw the weakest oil market since the market disaster of the mid-1980s. Average crude prices dropped below US$11 per barrel by mid-year because of several factors, including technological gains that have made the industry far more efficient in the discovery and extraction of oil.

Inteq’s technology director for drilling and evaluation in Celle, Volker Krüger, says the price of oil has a direct relationship on the industry as a whole. He says when the prices are low, companies tend to use only their existing wells, refraining from any new exploration.

But even this situation can create business opportunities for the entire Baker Hughes group of companies. Re-entry projects are one example. This technology, which is still in an early stage, involves drilling out of already-existing wells to better exploit the resources of a known reservoir. For the customer, it is a less risky alternative to drilling a new well.

Such possibilities excite Krüger. “The entire company is committed to innovation,” he says.

Kathleen Saal

a business journalist based in Munich

photos Baker Hughes Inteq