Explorer – a new generation of spherical roller bearings

Explorer bearings carry with them a variety of benefits, including:

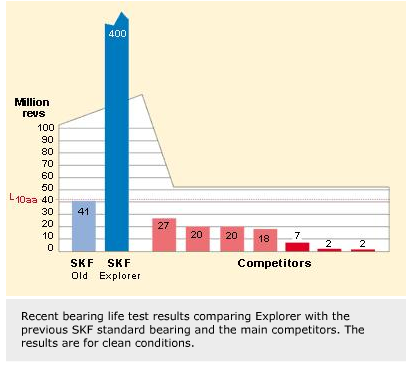

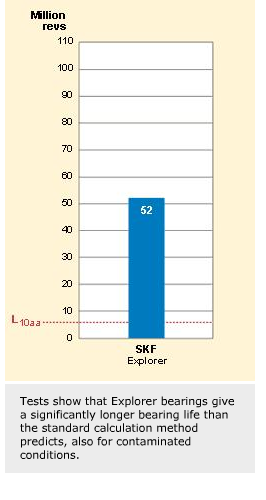

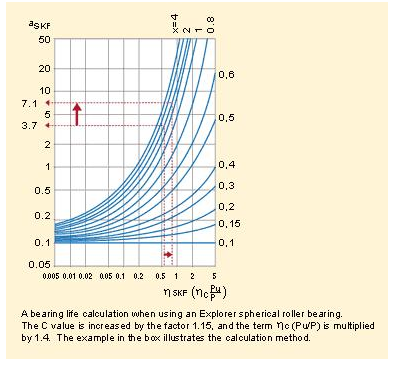

Explorer is a new performance class for standard spherical roller bearings that makes it possible to raise power density significantly. It also opens up the exploration of new customer applications.SKF has launched a new range of spherical roller bearings, named explorer, which establishes a new performance class. The impact of these bearings’ performance is so great that the improvement could not be predicted by standard bearing life calculations.

Accordingly, some modifications have been made.

Explorer bearings carry with them a variety of benefits, including:

- higher power density

- longer bearing life

- increased reliability

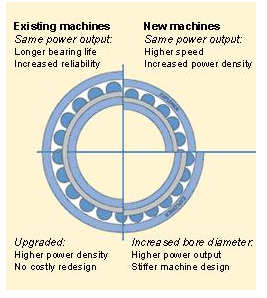

In a new machine design, increased power density can be achieved by choosing a smaller bearing size. This would make possible a more compact machine. Additional benefits also arise, including the ability to increase shaft speed, reduce power consumption, improve running accuracy and achieve lower noise levels and longer lubricant life.

Compact bearings

In some applications, Explorer will make it possible to change the bearing dimensions in other ways. For example, a larger shaft with the same bearing outside diameter can be chosen. Another option is to decrease the bearing outside diameter using the same shaft. Of course, the use of a decreased bearing width is a third option when realizing the benefits offered by Explorer.

For existing machines, Explorer offers a number of benefits. Also when the bearing is used as a replacement bearing, it will result in significantly longer bearing life and improved bearing reliability. The new bearings can also be used to upgrade an existing machine. If changing to Explorer bearings, the torque in a gearbox can be increased, for example, by 15 % to 25 %, depending on running conditions. If there is a need to increase bearing load for other reasons, Explorer will open up this possibility, too.

Other important benefits with the Explorer bearings are their higher precision, which allows for lower noise and vibration levels.

Improved performance

Application and use will determine the extent to which Explorer benefits can be realized. But Explorer bearings offer a wide range of opportunities to improve machine performance in an increasingly tough marketplace.

Explorer’s high performance results from a combination of changes inside the bearings. An extremely clean steel is used and refinements have been made to the heat treatment process. The internal bearing design has also been improved to reduce stress concentrations considerably on both macro and micro levels. And to achieve good bearing performance, the surface texture has been refined to maintain an optimum oil film between the contacting surfaces.

Considerable research and investment was required to achieve the high overall quality and optimum design. Accordingly, the performance of the Explorer spherical roller bearings has been achieved by the combination of extensive knowledge about application, design dynamics and efficient interaction between design and manufacturing. During the development process, sophisticated calculation tools have been used – tools that are unique in the bearing world.

Reliable design

One of the prerequisites to achieve the high performance of Explorer bearings is a sound and reliable basic design. SKF’s heavy-duty steel cages, the floating guide ring and the self-guiding rollers are all-important factors that contribute to this performance. They ensure that the improvements made are synonymous with improved reliability.

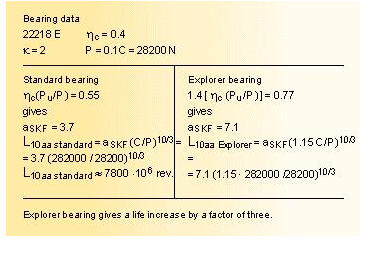

The impact of the improvements is so great that the real life of these bearings is much longer than that calculated using current life calculation methods. While other manufacturers still strive to reach bearing lives that equal the results given by present calculation methods, with Explorer bearings SKF has already moved far ahead. The introduction of Explorer makes the time ripe to refine the theory further with respect to the performance of these bearings.

To fully realize the potential of the Explorer bearings, knowledge about the bearing environment is important. One significant measure is to prevent contaminants from entering the bearings during mounting or operation. This may seem easy to achieve, but it can be quite tricky in applications subjected to tough environments. For this reason, the Explorer range also includes sealed spherical roller bearings. The seals efficiently prevent contaminants from entering the bearing during handling and mounting and keep contaminants outside during operation.

The seals provide the opportunity for an increase in bearing life by up to a factor of three and, under certain conditions, even more. This means that by using a sealed spherical roller bearing, an even smaller bearing can be used and a higher reliability can be achieved. The sealed bearings can be used in both grease- and oil-lubricated applications. Customers are offered a product that gives scope for a significant increase in power density. Choosing a smaller bearing saves money and gives higher reliability.

Håkan Lindgren and Joacim Fogelström

SKF Sverige AB, Göteborg, Sweden