Hard coating for heavy bearing duty

Diamond-like carbon coatings combine hardness with low friction, thus helping to eliminate wear and increase bearing service life.Hardness combined with low-friction bearing surfaces in bearing components can help eliminate smearing and other wear-related problems. This contributes to a significant increase in bearing service life. Diamond is the hardest material known to man and has these desirable qualities, but it is too expensive to make a full diamond bearing commercially viable. The answer is to apply a hard, thin coating on to the existing bearing steel. One such coating is called diamond-like carbon or DLC.

Diamond-like carbon coatings combine hardness with low friction, thus helping to eliminate wear and increase bearing service life.Hardness combined with low-friction bearing surfaces in bearing components can help eliminate smearing and other wear-related problems. This contributes to a significant increase in bearing service life. Diamond is the hardest material known to man and has these desirable qualities, but it is too expensive to make a full diamond bearing commercially viable. The answer is to apply a hard, thin coating on to the existing bearing steel. One such coating is called diamond-like carbon or DLC.

Hardness and low friction

DLC is the generic name for an amorphous mixture of graphite and diamond-type bonded carbon. Today this coating can be applied in extremely thin layers of only a few microns on to any SKF bearing. The DLC coating gives the bearing unique properties. It makes it possible to combine the endurance and toughness of a conventional steel body and the exceptionally low friction and considerable hardness of the DLC coating. The result is a bearing that has both high surface hardness and a very low coefficient of friction. To a certain extent it is possible through application of a DLC coating to tailor the future properties of the bearing. Surface hardness depends slightly on the process used. Typical values for SKF DLC coatings are of the order of 1,200 HV, compared with values of between 650 and 850 HV for bearing steel. Matching the mechanical properties of the coating and the steel is crucial for the performance of the coated component.

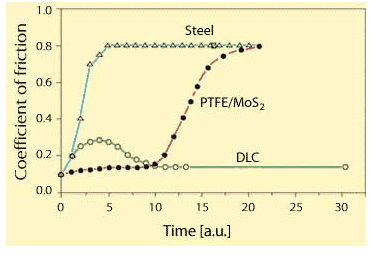

The preferred coefficient of friction for such coated bearings depends on the environment in which they are to be used. Since rings or rolling elements (or both) may be coated, several different coefficients of friction are offered. The lowest values represent the type of bearing where both the ring and rolling elements are DLC-coated. Under dry conditions, however, the wear life in a sliding test is greatly prolonged by coating only one surface with DLC, although further enhancements are possible by coating both surfaces. The reason for the increased bearing service life with DLC-coated surfaces is the very low coefficient of friction for such coatings, combined with the very high surface hardness. The friction values are actually very similar to values for low-friction materials such as PTFE and MoS2 and thus provide a solid lubrication effect.

There is one important difference between DLC and solid lubricants such as PTFE. DLC does not wear away at high pressures. Another unique feature of DLC is the running-in characteristics of the coating. Although it is very hard, a small portion of the surface transforms into a low-friction contact zone. This effect acts to protect the counter surfaces of the steel that otherwise would be damaged by the harder coating. Combined with the hardness, this effect results in an ideal solid lubrication condition.

Customer benefits

The properties of DLC offer unique benefits to the bearing user. Both laboratory and application evaluation of DLC-coated bearings demonstrate lower running temperatures and increased bearing life by typically five to 10 times, depending on running conditions. This is particularly relevant in cases involving low and zero load, which normally cause failure due to smearing damage.

The low friction also prevents wear and bearing seizure and allows running at lower temperatures in cases with poor lubrication and/or high speeds. This feature can be used to downsize lubrication systems and results in more environmentally friendly solutions. The high surface hardness coupled with the chemical nature of the carbon results in a higher resistance to abrasive and adhesive wear which extends life in harsh and dirty environments.

In addition, the solid lubrication effect of DLC-coated bearings make them ideal for applications with low-viscosity lubricant and in cases involving vibration or small movements that cause “false brinelling” or fretting corrosion. In most cases, coating a single surface will provide a satisfactory solution to these problems.

Prevention of smearing

So far, DLC-coated bearings have been used successfully in applications such as compressors, papermaking machines and hydraulic motors. In these applications, the coating helps prevent smearing damage in the bearings.

In compressors, for example, smearing due to zero load, vibration and low-viscosity lubrication are all problems that can occur and that are difficult to solve. With DLC-coated bearings, these problems can be overcome. One example of this is a screw compressor for pumping ammonia where DLC-coated bearings solved the smearing problem. In addition, with DLC-coated bearings, it is possible to eliminate large, external lubrication systems, which allows space and weight savings and, perhaps most important, less environmental impact.

Soft calanders, which are giant rolls in the final stage of a paper mill, often have problems related to the very wide load range and zero load situations, which occur frequently. The result is sliding, microwelding and, eventually, smearing damage to the bearing. In machines equipped with DLC-coated bearings, there is low heat generation and DLC resistance to microwelding. This solution has proved very successful and superior to TDC (thin dense chrome) coating solutions in similar situations for papermaking machine problems, assuring a longer bearing service life.

Hydraulic applications such as pumps and motors are another major application area for DLC-coated bearings. The hydraulic motors benefit from the low-friction attributes of the coating and the fact that the bearing wear is significantly reduced. Today most hydraulic applications are lubricated with low-viscosity oil, which in some cases causes friction and wear. In fact, the solid lubrication effect of DLC-coated bearings has been shown to extend the bearing service life in certain hydraulic applications by up to 10 times. In addition, other hydraulic applications require expensive, sealed and separate lubrication systems to provide the necessary operating conditions. DLC-coated bearings remove the need for such systems.

The future for coated bearings

DLC coating is a relatively new bearing technology. Much of the research within SKF has been focused on developing this exciting range of products further.

One of the most important requirements is that the coating adheres to the bearing surface, even at high contact pressures. Physical or chemical vapour deposition is the technology behind these coatings. These techniques are moving in on the established wet chemical methods used for coating bearings. Research and development in this area are moving very quickly, with new concepts and new types of coatings introduced all the time.

Currently in most applications, only bearing rollers are coated with the SKF DLC coating. This is frequently sufficient to solve the particular problem. Most bearings, however, could be completely coated to provide an optimal solution.

Dr. Hans Sjöström, materials science expert at SKF, says: “Solutions based on coatings are becoming more and more widespread. This technology is especially well-established in industries such as cutting, moulding and food processing, but lately the automotive industry has also started to work with DLC coatings to lower the general energy consumption in their products.” Sjöström says the current coating developments within SKF are the beginning of a whole range of possible coating concepts. “SKF provides customer value,” he says. “If the demands from customers are changing, so must we.”

Anna Hultman and Hans Sjöström,

SKF Nova AB, Göteborg, Sweden