Integrated by design

With more than 80 years of experience in the machine-tooling industry and a keen eye on the future, US-based Liberty Precision Industries is positioning itself ahead of the competition – offering integrated, innovative and cost-effective turnkey solutions to meet the demanding specifications of high-volume manufacturers.

Summary

One essential piece of the puzzle in Liberty’s design for the DaimlerChrysler project is its need for precision, high-speed two-, three- and four-axis machining modules and cutting spindles.

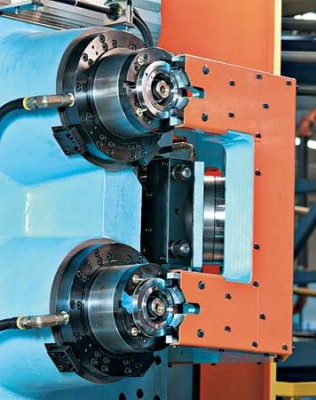

Russell T. Gilman, a division of SKF USA Inc, is a machine-tool systems and component supplier that specialises in linear motion products and rotary motion spindles. It actually built three different multi-axis modules for Liberty’s DaimlerChrysler project: a two-axis module, a dual-spindle three-axis module and a dual-tilting spindle four-axis module. The Gilman 19.5 kW, HSK 100 spindle can be used in any three- or four-axis module.

Liberty and Gilman had planned from the beginning to standardise the lower slide units and the vertical travel columns for use on all 21 machines, says Craig Zacher, Gilman’s vice president of manufacturing. The benefit for the customer is speed of design, lower-cost manufacturing and commonality of replacement parts, such as ball screws, bearings, cylinders and profile rails.

The four-axis tilt spindle design uses permanent magnet motor technology, direct encoder feedback for positioning and hydraulic clamping for rigidity during the cutting cycle. The components and assembly were also done at Gilman.

It’s also worth noting that, in the DaimlerChrysler application, the dual-spindle machine must position accurately to +/- 5 microns.

Typically, Gilman has 18 to 20 weeks of lead time to deliver such an order. Liberty had made certain commitments to the customer. To help meet that commitment, Gilman had to design and build the first machine in 12 weeks, following that with two to three machines completed each week. Shipping of spindles started after 11 weeks, including design.

“It was a tremendous challenge; it took the entire Gilman company – and its suppliers – to rally together to meet the delivery requirement,” says Zacher, who credits Liberty for not changing the delivery commitment it made to DaimlerChrysler.

It’s like one-stop shopping, says Mark Wiktorski, corporate development manager at Liberty Precision Industries, describing the strategic advantage his company offers to customers in the automotive, appliance, small-engine and industrial-component industries.

Customers no longer have to deal with multiple vendors, he says. “That’s all taken care of with Liberty.”

As a systems integrator, Liberty offers customers single-point, start-to-finish accountability for all components and services. This includes project management for system design, system building and system qualification, as well as extensive manufacturing services and field support.

“There’s nothing secret about what we do. It’s just how we do it, how we manufacture it, how we manage it, how we service it,” Wiktorski explains.

Design challenges

On this day, the main focus of our discussion is a massive system being built on the floor of Liberty’s 9,300-square-metre manufacturing facility in Rochester, New York. The system is destined for DaimlerChrysler, scheduled for delivery in June 2003.

Engineering manager Al Bingeman and his team developed the concept and specifications for this project, valued at 33 million US dollars. It includes six turnkey manufacturing systems – all of which will be used in the production of suspension components for the automaker’s LX vehicle body type.

The system comprises five flexible rotary-dial transfer machines that incorporate 21 dual-spindle multi-axis units and 10 stand-alone twin-spindle machining centres. Stations for material handling, inspections and part washing are also included, along with a powered conveyor system.

Bingeman explains that the DaimlerChrysler project posed several challenges that were unique in terms of Liberty’s past experiences. These included incorporating twin-spindle technology into a rotary transfer machine, creating a twin-spindle tilt axis unit for six of the stations, and building a tool storage unit that worked in conjunction with the newly designed tilt axis.

“There are definitely things you have to take into account on a twin-spindle machine versus a single-spindle machine,” Bingeman says. “On a single-spindle machine, you can compensate electronically in the programming for some of your accuracy errors. In a twin-spindle machine, you can’t do that, so tighter tolerances are necessary.”

Factoring in speed

Speed was also a prime consideration. “We were supposed to achieve a ‘chip-to-chip’ time of less than six seconds,” Bingeman says. This refers to the time from when the machine stops cutting one hole on a casting and goes back and changes tools, to when it starts making another hole.

The complete machining cycle, which lasts only 45 seconds, yields two finished parts. Looked at in a broader perspective, this amounts to an overall production volume of about 150,000 parts annually.

But that’s not all. During component production, the movement of the machine itself is accelerated up to a g force of 0.65. That’s a maximum velocity of about six metres per second.

“This is one of the fastest machines of this type that we’ve built,” Bingeman says, adding that the harsh environment created by these forces must be addressed during the design phase.

Establishing partnerships

Liberty’s model is different from that of other manufacturers of the same type of equipment because it isn’t vertically integrated. This means Liberty does not manufacture everything it sells.

Instead, the company teams up with some of the industry’s best equipment and component suppliers in what it calls Strategic Integration Partnerships, or SIPs.

Wiktorski explains that Liberty purposely chooses not to compete with these suppliers. Instead, it uses their state-of-the-art technologies and products, incorporating them into customised solutions for its customers. The result is higher reliability, faster delivery and lower costs.

“We’re leveraging their experience and their innovation and applying that to our products, without us spending the time and money to do that,” Wiktorski explains. The key benefit of this strategy, for both the company and its customers, is timely access to leading-edge technologies. This allows Liberty to concentrate on its strength, which is designing turnkey manufacturing systems and process capabilities.

The goal is to create partnerships, not only with suppliers, but with customers and employees, too. Liberty’s success is measured by the fact that about 80 percent of the company’s sales are repeat business.

Costs and savings

For high-volume manufacturers such as DaimlerChrysler, part cost is a key consideration. They tend to look for leaner, more cost-effective solutions in a bid to keep their costs down.

On this particular project, Liberty performed what it calls “life-cycle cost” calculations, which look at such things as power consumption, maintenance, labour, tooling cost, part cycle time and coolant disposal. In its analysis, the company determined that twin-spindle machines (as opposed to a single-spindle, hybrid alternative) would yield the automaker more than 500,000 US dollars in savings per year.

Liberty designs and builds its systems to be modular, so that they can be disassembled and shipped to the customer in about three days. Re-assembly on the customer’s production floor is equally swift. An added benefit is flexibility. Because of the “plug and play” mindset during the design of Liberty’s systems, the company can reconure and retool the dial units for the production of new parts after the original production programme has concluded.

But even as customers try to find new and innovative solutions, Liberty, too, looks for new products to add to its portfolio.

“Innovation doesn’t stop at ‘okay we have a product, that’s it,’” says Wiktorski. Liberty’s product line, he says, is always evolving.

An eye on business

Ninety-five percent of Liberty’s business focuses on the production of a diverse range of components for the automotive industry. The company’s speciality is in the manufacturing of steering knuckles and other suspension components, as well as fuel-system components.

“We want to be able to develop a process for the industry that is very stable and proven,” says Wiktorski.

Liberty’s main customers include not only original equipment manufacturers such as Ford, GM and DaimlerChrysler, but also, increasingly, tier suppliers in the automotive industry, such as Metaldyne, Delphi and TRW.

With machining systems in facilities across the United States and Europe, the company is currently eyeing a further expansion – into China.

The aim is not only to service Liberty’s existing customer base, which is also establishing operations there, but to penetrate the vast possibilities that are offered by doing business in that region.

But no matter where Liberty does business, says Wiktorski, customer service will always remain a top priority. He notes that the company’s repeat business comes not only from the capabilities of its equipment, but also from the people who manage and service it.

“Because we sell our customers the entire machining complex, they only have one person to call – that’s Liberty,” Wiktorski says. A company’s reputation for service can be key to winning or losing future orders, he adds.