The technical requirements on bearings in modern printing presses are very demanding, particularly for printing cylinders.Main cylinders or printing cylinders represent the most important section within a printing press for bearings. Here the printing quality depends largely on the running accuracy of these rollers. Generally speaking, the bearing performance for printing cylinders is close or equal to that for machine tools.

SKF is a major supplier to the printing industry and offers a wide selection of bearing types and tailored solutions. Over the years, different bearing concepts have been established and many innovations have been driven by the printing industry’s need for more complex solutions incorporating associated components. The printing industry’s main demands are for higher machine productivity and reliable performance up to 24 hours a day. SKF supports this industry by supplying high-quality products as well as continual developments and innovations in products and technology.

Spherical roller bearings

For more than 30 years SKF spherical roller bearings have been employed in high-precision printing and coating applications. The bearings have been widely used on plate and blanket cylinder assemblies of printing presses and related machines such as perforators, cutters and slitters.

SKF offers two different spherical roller bearing designs to the printing machine industry. Preloaded and torque-tested bearings have design characteristics that make them interchangeable. All these bearings are run in and torque tested and the inner rings have modified side faces to give accurate preloading after correct mounting. They are interchangeable with other bearings of the same size and designation.

The suffixes applied to these bearings are VA759 and VA760.

Bearings of the other design have tolerances to class P5 and a C1 radial internal clearance. The actual value of the radial clearance as well as the location and magnitude of the inner ring runout high point are marked on the side face of the bearing. The designation suffix is VA772.

Taper roller bearings

Taper roller bearings are very often used as the locating bearing for the press cylinders or within the transfer cylinders for sheet-fed offset presses. These special units have a tailored design based on a double-row taper roller bearing in a back-to-back arrangement. A spacer ring is placed between the two inner rings and creates preload in operation. The extra-thick one-piece outer ring incorporates the function of the conventional outer sleeve. Oil is supplied through ducts in the outer ring to ensure efficient lubrication. The bearings can be designed with a running accuracy up to tolerance class P4 and are ready to mount, which means that no adjustments are required after mounting.

Compared with conventional bearing arrangements, these units are easier to mount, and the absence of subsequent adjustment means that faulty mounting is eliminated. Fewer individual components offer a more compact design, and the bearing stiffness is enhanced both axially and radially. On the opposite side of the printing cylinder, cylindrical roller bearings or printing cylinder bearing units (PCU) are recommended.

Main cylinder arrangements

Conventional solutions for the main cylinder arrangements are cylindrical roller bearings. For blanket cylinders, these bearings can be mounted in an eccentric housing (sleeve) which acts as a plain bearing. By turning the eccentric sleeve, the printing cylinders can be adjusted. Cylindrical roller bearings used for this application are double-row designs based on series NNU 49 and NN 30. Rollers of the NNU type bearings are guided between the flanges of the outer ring, those of NN type bearings between the flanges of the inner ring. The bearings have tighter tolerances than normal (SP) and can be supplied with cylindrical bore or with tapered bore (taper 1:12). To achieve efficient lubrication, all bearings are provided with an annular groove and lubrication holes in the outer ring (W33). Cage designs are available in brass and for larger quantities in polyamide 6,6.

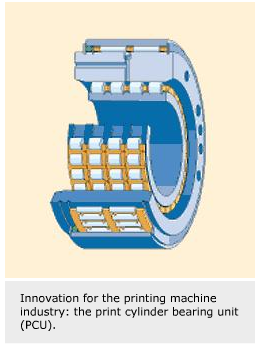

PCU concept

SKF has developed the units together with leading manufacturers of printing presses. The special units incorporate the cylindrical roller bearing design and the eccentric housing, as well as additional components. Today SKF offers five different designs of specially tailored cylindrical roller bearings and printing cylinder bearing units: two-ring, concentric; two-ring, one-eccentric; three-ring, one-eccentric; three-ring, two-eccentric; and four-ring, two-eccentric.

In addition to the high running accuracy of the cylindrical roller bearing, these units offer such advantages as zero clearance after assembly, easy and quick mounting, high radial stiffness, smooth eccentric adjustment and low friction.

Challenging area

Main cylinders of printing presses represent a challenging area for SKF. The industry is increasingly looking for further improvements of printing quality at higher speeds, as well as clever solutions that offer lower total cost of the machine. SKF already offers a wide selection of different bearing designs specially tailored for the printing industry and continues to be a major driver of new developments and innovations using all modern technologies.

Werner Palmetshofer,

SKF Österreich AG, Steyr, Austria