Never underestimate the power of boil-off gas

Magnetic bearing technology from SKF is helping liquefied natural gas carriers transform a persistent problem into a source of power for cleaner propulsion.

Natural gas is the fossil fuel of the moment. The mixture of methane and other gaseous hydrocarbons created by the decomposition of ancient plants and animals already provides around a quarter of the world’s primary energy. By 2025 it is expected to surpass coal to become the second-biggest component of the global energy mix behind liquid petroleum.

End users like gas because it is easy to use and produces fewer harmful emissions than rival hydrocarbons. That has helped it find a vital role in a host of applications, from domestic cooking and heating to electricity generation, industrial processes and chemicals production.

Rising demand for gas has driven significant investment in the infrastructure needed to transport, process and distribute the fuel. Most gas is carried from source to point of use through pipelines, but recent years have seen substantial growth in marine transport. Putting gas onto ships is more cost-effective than pipelines over longer distances, and avoiding the need for fixed pipelines offers additional flexibility for buyers and producers. Today, just over a third of the world’s gas is transported in liquid form, and that proportion is on the rise, thanks to the need to connect producers and customers in regions without pipeline links.

“Our magnetic bearing solution is ideal for the compact, high-speed turbomachinery that companies need to compress, cool and re-inject LNG back into a vessel’s tanks,” says Christophe Durand, product owner for boil-off application development at SKF.

Keeping your cool

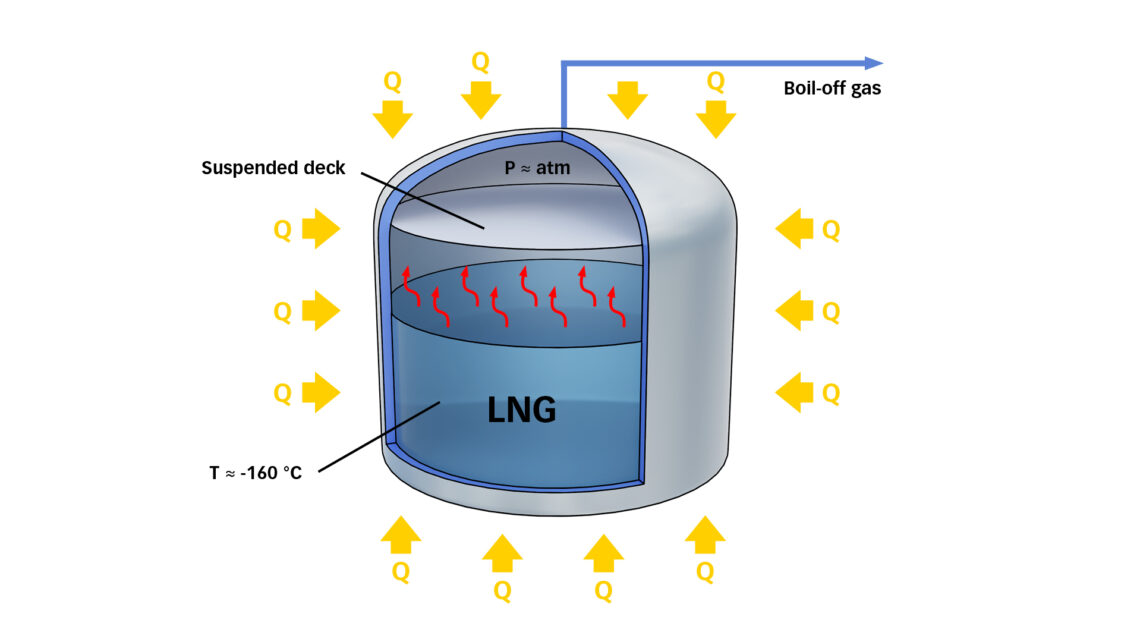

Modern LNG carriers hold their cargo in highly insulated tanks. The largest vessels in service today can carry 266,000 cubic metres of the fuel. Despite the advanced technologies used in their construction, however, LNG tanks can’t perfectly protect their contents. The motion of the vessel and heat from pumps within the tanks and from the external environment add energy to the cargo. As a result, a small fraction of the LNG is continually turning back into its gaseous form.

The modular approach has multiple advantages for our customers.

Christophe Durand, product owner for boil-off application development at SKF.

Ignoring this boil-off gas is not an option for LNG carriers. Without proper handling, the gas would cause the pressure in the tanks to rise, potentially to dangerous levels. Early LNG carriers would vent boil-off gas into the atmosphere, but that option is undesirable for environmental and economic reasons. So modern vessels are fitted with specialized equipment for the safe handling of the material.

The simplest use for boil-off gas is to power the vessel with it. Modern LNG carriers are equipped with dual-fuel engines that can burn conventional oil when the ship is travelling empty, then use gas whenever it is available. That approach saves money for the operators and offers environmental benefits too, since gas has a lower carbon footprint than the heavy oil used in marine transport, as well as lower emissions of sulphur and other pollutants. Gas power isn’t a complete solution to the boil-off problem, however, since vessels often produce more boil-off gas than they need for propulsion.

Putting it back

Another way of dealing with excess boil-off gas is to put it back into the tanks, by equipping vessels with miniaturized versions of the same technology used to cool and liquefy the fuel prior to loading. With decades of experience in gas-handling applications, it’s no surprise that SKF has been closely involved in the development of on-vessel reliquefaction systems since carriers started to apply the technology at the beginning of the 21st century.

“In the early 2000s we worked with several customers in the gas sector on projects to develop motors and bearing systems for liquefaction,” Durand recalls.

Those projects were successful, but developing customized solutions for such a safety-critical application is time-consuming and requires intensive engineering. In 2016, the SKF team decided to take a different approach. “As the LNG sector started to grow more rapidly, our customers were looking for a more cost-effective approach to the equipment used on these vessels,” Durand says. “We made the decision to use a standardized module that would meet their needs.”

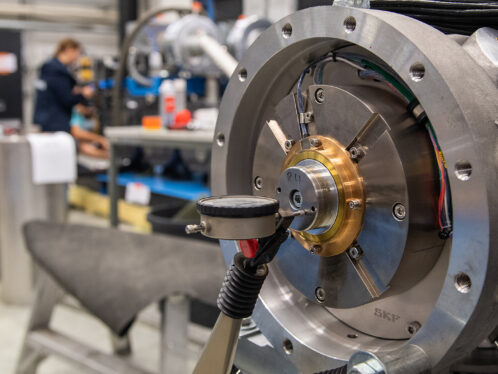

After months of intense design and testing work, the new system was ready for delivery to customers the following year. The SKF solution comprises a 175-kW motor, active magnetic bearings and a control system in a compact, robust format that end users could integrate into their own reliquefaction systems. In a typical customer application, the motor is mounted between two pieces of turbomachinery, a compressor and a turboexpander, which spin on a single shaft.

“The modular approach has multiple advantages for our customers,” says Durand. “It reduces the time and effort required to design and certify their equipment, and it greatly simplifies management and maintenance for end users.”

SKF customers have taken the modularization even further in their end-product designs. Reliquefaction systems are manufactured as a self-contained plant in a range of standard sizes. “A unit for a small LNG vessel might have two SKF machines installed, while the largest applications use seven,” says Durand.

Modern reliquefaction machines are designed to work seamlessly with gas propulsion. The system can divert a fraction of the boil-off gas to the vessel’s engines before the rest is returned to the tank. And thanks to the highly reliable, durable magnetic bearings, reliquefication doesn’t add much to the workload of carrier crews. The systems operate fully automatically and require maintenance only after five years of operation.

Continued expansion

As the LNG business continues to grow, SKF has been expanding its offering. It has developed a larger 900-kW version of its integrated motor and magnetic bearing solution suitable for higher-capacity reliquefication systems. “As LNG vessels have become bigger, customers want to take advantage of the higher efficiency of larger equipment,” notes Durand.

The SKF LNG motor solution has proved so versatile that it is also being applied in an entirely different approach to boil-off gas management. Subcooling solutions are designed to condense the gas inside a vessel’s tanks. They do that by drawing liquid methane from the tanks, cooling it to an even lower temperature and then spraying the subcooled liquid through the vapour in the top of the tank.

For LNG equipment makers, the biggest challenge in the short term is likely to be keeping up with demand. The global fleet of LNG carriers is growing by around 10 percent every year, with about 650 vessels in operation today. With orders for a further 216 vessels on their books, shipyards will be busy for several years to come.