SKF has developed a new generation of oil and grease seals specifically for heavy-duty applications. These seals are intended for use in agricultural and similar machinery where environmental and operating conditions can be harsh.Tractor design during the 1990s has moved towards the development of improved sealing technology for oil and grease seals for transmission components. Seals need to be able to perform in all types of environment, regardless of the application.

The new generation of seals developed by SKF is designed to perform to the same level regardless of whether the tractor is used for light duties or in less advantageous conditions such as the rice fields of India.

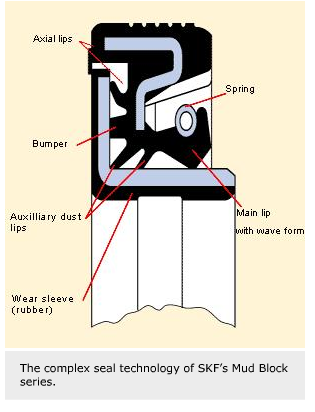

Traditional seal designs consist of a radial lip (with or without hydrodynamic features), a garter spring and static seal between the outside diameter and housing. “Mud Block” is the name given to the series of seals created by SKF Seals Division at RFT in Villanova d’Asti, Italy. The seals represent an increase in the complexity of sealing technology, compared with a standard oil seal design. The improved protection the Mud Block seals provide is the result of the design of its lips. Often the failure of a seal in transmission is due to water and mud ingress at the radial lip. In the Mud Block series, the geometry of the seal design has been altered to provide the optimum protection against water and mud ingress at this point.

The new design offers a number of standard features throughout the series. These include a stop bumper between the sleeve and seal that facilitates assembly and ensures correct position of the axial lip. The outer surfaces of the seal and the sleeve inner diameter are rubberised to provide good corrosion protection. Also, the inner lips are pre-lubricated with highly water-resistant transmission grease. Consequently, this offers better reliability during assembly and replacement in the field and eliminates the need to carry out shaft machining.

Tailored design

The seals are tailored to the customer’s requirements for assembly. Full rubber outside diameter designs can be provided with or without a flange, and the outside diameter can be fabricated half in rubber and half in metal. The inner radial lip can be varied to offer oil or grease sealing, i.e. a standard lip design with garter spring for oil sealing and several radial lips fabricated in rubber for grease sealing.

Mud blocks can be fabricated in a variety of elastomer materials, depending upon the component applications and their particular operating conditions. The range of materials includes nitrile, polyacrylate and fluorinated elastomeric compounds. Seals are required on non-driving wheel hubs that usually operate at low speeds, as well as on pinions, which experience high revolutions and high temperatures.

The performance of the Mud Block series has been confirmed in both laboratory testing at RFT in Italy and in field tests carried out in collaboration with key customers.

Mauro Sassi

RFT Industrial Oil Seals, Italy