New SKF IEC offers easy online calculations

A new SKF Interactive Engineering Catalogue (IEC) is now available online in seven languages at www.skf.com. It offers a wealth of information plus the ability to perform quick, easy and accurate online calculations.

The new SKF General Catalogue was announced at the 2003 Hannover fair in Germany. The print version – 1,100 pages in full colour – is currently available in both English and German, with more language versions to be available soon. The previous SKF General Catalogue was translated into 16 languages and this edition is expected to surpass that number.

The electronic version of the catalogue, the SKF Interactive Engineering Catalogue (IEC), is now available online at .1).

Some of the more important ones are shown here; screen shots are provided, incorporating an example, to show how easy the program is to use.

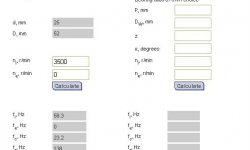

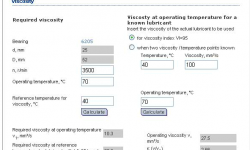

Required viscosity

To reduce friction and wear, rolling contact surfaces need to be separated by an oil film. The thickness of the oil film depends not only on the relative speed of the rolling elements (n and dm values), but also on the roughness and roughness deformation in the contact area. To maximize the effects of the lubricant and increase bearing service life, SKF was able to define optimal surface roughness and manufacture bearings to those specifications. In doing this, SKF identified the values of requisite lubricant viscosity under different operating conditions.

The graphs published in the SKF General Catalogue are valid for modern lubricants with a viscosity index (VI) of 95. However, some lubricants have a different VI. The IEC provides a calculation program to determine the requisite lubricant viscosity for all viscosity indexes.

Data required for online calculation are:

- Bearing designation;

- Rotational speed;

- Operating temperature; and

- Viscosity of the lubricant at reference temperature (for lubricants with VI=95), or

- Viscosity of the lubricant at two different temperatures, i.e., 40 °C and 100 °C (for lubricants with a VI other than 95).

The calculation output is ( .2):

- Required viscosity at the operating temperature;

- Operating viscosity; and

- Viscosity ratio (

).

).

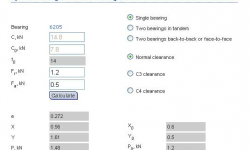

Equivalent bearing loads

Although not difficult to calculate manually, the program in the IEC quickly provides the equivalent bearing loads needed to calculate bearing life.

P = X Fr + Y Fa

and

P0 = X0 Fr + Y0 Fa

Data required for online calculation are:

- Bearing designation; and

- Actual radial and axial bearing loads.

The calculation output is (.3):

- e, limiting value;

- X, Y, X0 and Y0factors;

- Equivalent dynamic bearing load; and

- Equivalent static bearing load.

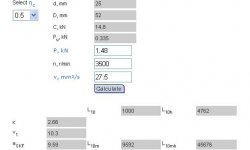

SKF rating life

In the 1950s, ISO standardized the calculation of the basic rating life. That formula is still valid today:

L10= (C/P)p

where

L10 = basic rating life (at 90 % reliability), millions of revolutions

C = basic dynamic load rating [kN]

P = equivalent dynamic bearing load [kN]

p = exponent of the life equation

p = 3 for ball bearings

p = 10/3 for roller bearings

For modern high-quality bearings the basic rating life can deviate significantly from the actual service life in a given application. Service life in a particular application depends on a variety of influencing factors, including lubrication, the degree of contamination, misalignment, proper installation and environmental conditions.

Therefore ISO 281:1990/Amd 2:2000 contains a modified life equation to supplement the basic rating life. This life calculation makes use of a modification factor to account for the lubrication and contamination condition of the bearing and the fatigue limit of the material.

Lnm=a1 aSKF (C/P)p

where

Lnm = SKF rating life (at 100 – n % reliability), millions of revolutions

a1 = life adjustment factor for reliability

aSKF= SKF life modification factor

C = basic dynamic load rating [kN]

P = equivalent dynamic bearing load [kN]

p = exponent of the life equation

p = 3 for ball bearings

p = 10/3 for roller bearings.

The SKF life modification factor aSKF represents a complex relationship between the fatigue load limit ratio (Pu/P), the lubrication condition (viscosity ratio  ) and the contamination level in the bearing (

) and the contamination level in the bearing ( c). Values for the aSKF factor can be obtained from diagrams published in the General Catalogue and IEC as a function of the bearing type, of

c). Values for the aSKF factor can be obtained from diagrams published in the General Catalogue and IEC as a function of the bearing type, of  c (Pu/P) for SKF standard and SKF Explorer bearings and different values of the viscosity ratio

c (Pu/P) for SKF standard and SKF Explorer bearings and different values of the viscosity ratio  :The

:The  c factor considers the contamination level of the lubricant in the bearing-life calculation. The effect of contamination on bearing life is complex because the influencing parameters are difficult to quantify. Therefore, it is not possible to provide precise values for

c factor considers the contamination level of the lubricant in the bearing-life calculation. The effect of contamination on bearing life is complex because the influencing parameters are difficult to quantify. Therefore, it is not possible to provide precise values for  c that would have general validity. However, guideline values are provided in table 1.

c that would have general validity. However, guideline values are provided in table 1.

SKF Explorer bearings, which are also included in the new IEC, represent a new performance class of rolling element bearings that provide a substantial improvement in key operational parameters relevant to the bearing type and its typical applications. This new level of superior performance represents the blending of SKF’s applications knowledge with its expertize in tribology, materials development, design optimization and manufacturing.

Using advanced analytical and modelling techniques and supporting testing, SKF engineers were able to confirm that SKF Explorer bearings provide a significant improvement in key operational parameters.

These parameters, according to bearing type and application, include noise, vibration, service life, dimensional stability, dynamic load-carrying ability and heat generation (friction torque). Because these parameters are not adequately factored into standardized life calculations, SKF Explorer bearing life is calculated with modified factors, which takes key operational parameters into account.

SKF Explorer bearings are characterized by a number of technical improvements. Some important ones are:

- Improved bearing steel;

- Unique SKF heat treatment procedures; and

- Improved surface finish.

Data required for online life calculations are:

- Bearing designation;

- Bearing equivalent load;

- Rotational speed;

- Viscosity at operating temperature; and

c value (table 1).

c value (table 1).

The calculation output is (.4):

- Basic rating life in million of revolutions (L10) and operating hours (L10h);

- SKF rating life in million of revolutions (L10m) and operating hours (L10mh).

The example (.4) also shows the importance of the aSKF factor and the bearing being SKF Explorer. The rating life of an SKF Explorer bearing is some eight times longer than the basic rating life.

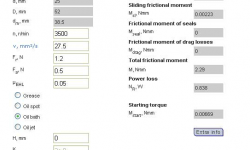

Frictional moment

SKF has a completely new approach to accurately calculating the frictional moment in a bearing. Four different sources must be taken into account:

M =  ish

ish  rs Mrr + Msl + Mseal + Mdrag

rs Mrr + Msl + Mseal + Mdrag

where

M = total frictional moment [Nmm]

ish = inlet shear heating reduction factor

ish = inlet shear heating reduction factor

rs = kinematic replenishment/starvation reduction factor

rs = kinematic replenishment/starvation reduction factor

Mrr = rolling frictional moment [Nmm]

Msl = sliding frictional moment [Nmm]

Mseal = frictional moment of the seals [Nmm]

Mdrag = frictional moment of drag losses, churning, splashing etc. [Nmm].

This approach identifies the sources of friction in every contact occurring in the bearing and combines them; in addition the seal contribution and additional external sources can be added as required to predict the overall frictional moment. Since the model identifies and accounts for each contact in the raceways and flanges, changes of design and improvements of the surfaces can readily be taken into consideration, making the model more able to reflect improvements in SKF bearing designs. Detailed information on calculation of the frictional moment can be found in the SKF General Catalogue and the IEC.

The formulae to calculate the frictional moment from each source are very complex. However, the IEC can perform these calculations quickly and accurately, provided the following information is available:

- Bearing designation;

- Actual radial and axial loads;

- Rotational speed;

- Viscosity at operating temperature;

- Friction coefficient for full film conditions (if different from standard); and

- Type of lubrication (eventually oil level H)

The calculation output is (.5):

- Rolling frictional moment;

- Sliding frictional moment;

- Frictional moment of the seals (if any);

- Frictional moment of drag losses (if any);

- Total frictional moment; and

- Power loss.

Bearing frequencies

Condition monitoring of bearings provides an opportunity to obtain maximum bearing service life. However, to monitor a bearing, the vibration data for that bearing must be available. The IEC has the program to calculate vibration parameters.

For standard SKF bearings following data is needed:

- Bearing designation; and

- Rotational speed (inner and/or outer ring where applicable).

The program will also calculate vibration data for other bearings provided internal bearing data is available. The calculation output is (.6):

- Frequencies needed to effect condition monitoring.

The IEC offers a number of user-friendly calculation facilities. Further additions are foreseen and will be implemented in the near future.

Basis for calculations

The calculation results shown on the screen shots are based on the following:

A 6205 SKF Explorer deep groove ball bearing is to operate at a speed of 3,500 r/min in an oil-lubricated gearbox under the following operating conditions:

- Actual radial bearing load: Fr= 1.2 kN

- Actual axial bearing load: Fa= 0.5 kN

- Inner ring rotation, stationary outer ring

- Operating temperature + 70 °C

- Oil bath lubrication

- Oil level H = 2,5 mm above the edge of the outer ring raceway under static conditions.

- Mineral oil with a kinematic viscosity v = 100 mm2/s at 40 °C.

- Rather clean operation

c = 0.5

c = 0.5