Summary

Global partnership

Bearings are where the whole mechanical process of offset printing begins, and SKF bearings are a feature of many Heidelberg presses. SKF and Heidelberg have cooperated on the design of several customer-specific solutions for bearing challenges in the past. But now, as a global company with global strategies, Heidelberg has entered into a global partnership with SKF to provide it with bearings throughout the world. Under the agreement, which was signed two years ago, Heidelberg coordinates its bearing needs from its five production centres in Germany, France and the United States and presents them as a package to SKF in Schweinfurt. According to Günter Stephan, head of purchasing mechanics at Heidelberg, this arrangement has cost advantages for both companies.

Formerly each plant held its own negotiations with its national SKF subsidiary. Now, although the negotiation is done globally, each production site is still supplied locally, guaranteeing that the local SKF team is closely in touch with what is going on there. When one of Heidelberg’s plants develops a new product, the initial order for bearings is handled locally. If Heidelberg decides on SKF as the production supplier, then that order goes onto the global list.

Long a leader in offset press manufacturing – a common printing method – Germany’s Heidelberg took a hard look at itself in the new digital world.When you’re already a market leader, it’s not always easy to know what to do next. Heidelberger Druckmaschinen AG confronted this problem in the rapidly changing world of the 1990s.

Founded in the 19th century, Heidelberg has long been one of the world’s leading manufacturers of offset printing presses. Some 400,000 Heidelberg presses are currently running in 240,000 printing firms around the world. The company has 24,000 employees in 170 countries, and in the last financial year it turned over 7.7 billion German marks (USD 3.8 billion), 82 percent of it abroad.

But by 1993, it was clear that its tradition of excellence was not enough. Printing technology and the world were changing, and Heidelberg would have to respond to those changes. Heidelberg took a long, steady look at itself and asked where it wanted to go, says Keith Dalton, senior vice president and head of corporate strategy.

The decision that Heidelberg took in 1995 was one that many other companies reached around the same time. It was no longer enough to produce first-rate products – you had to put them in a context, and that context was the customer. “The customer was no longer willing to be an expert himself,” Dalton says. “He doesn’t have the time or the money to keep ahead of the technology, and as a result he expects more from the supplier.”

Strategic purchases

Heidelberg decided to become a systems provider. Within five years it had made a number of strategic purchases to extend its range. With the acquisition of the pre-press specialist Linotype-Hell, and several manufacturers of post-press equipment, including the Stahl Group, as well as Eastman Kodak’s Office Imaging division, Heidelberg could handle pre-press (technical processes before print such as photo scanning or retouching), press (print) and post-press (all technical processes after printing such as binding or varnishing) from one address. “We had a choice – make or buy,” Dalton says. “In the old days, we would have probably put lots of money into the project and developed our own product, but there isn’t time for that anymore. The technology is moving too quickly.”

But Heidelberg has done more than just become a single address for printing needs. From being a systems provider, it has turned into a solutions provider. Few people are interested in buying a printing press for its own sake. They want a way of turning text, design and paper together into printed materials – and they only want that because a customer needs it. Heidelberg takes the needs of printers seriously, says Adriana Nuneva, of the corporate marketing division, and that’s why the company is presenting a new concept in May at DRUPA 2000, the industry’s biggest trade fair. “We’ve divided the market into different segments, and we offer different strategies for each segment,” Nuneva says. As a result, Heidelberg’s display at DRUPA features nine conceptual islands, each featuring solutions for a particular type of printing.

The new approach starts with the sales representatives, Nuneva says. “They analyse the business models of the customer and try to develop an appropriate concept for precisely that customer’s needs. And then the representative can propose the right equipment, the right service package, maybe even a training programme.” Being a “solutions provider” means that Heidelberg has to offer an open platform. It’s no solution if you can’t integrate new Heidelberg equipment into a system that already contains machines from other manufacturers. She sums up the reasoning behind the new approach: “We have a responsibility towards our customers because they are loyal to us. If our customers do well, then so do we.”

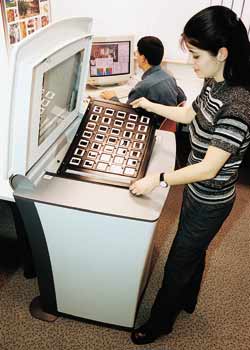

This orientation towards the customer is evident in the 4,000-square-metre “Solution Centre” at the company’s Heidelberg headquarters. Thomas Fichtl of corporate communications says the Solutions Centre is itself one of Germany’s largest printing shops. “People want to see before they buy, and they can bring a printing job with them, to see if the machines offer what they promise,” he says. Here customers can watch plates being made to their specification, then watch the job as it is printed, folded, cut, stitched and packed. The centre’s digital division is mostly concerned with pre-press processes, such as “computer-to-film” and “computer-to-plate.” Joint ventures are important here. Heidelberg is cooperating with Microsoft on colour control, with SAP (systems, applications, and products in data processing) on integrated software solutions and with WAM!NET on digital communications. But the digital division also offers digital printing solutions, such as the new Digimaster 9110, a black-and-white printer capable of 110 sheets a minute. The Digimaster, previously sold as the Kodak DigiSource 9110, marks the first move in a process of bringing all the products of recent acquisitions under the Heidelberg brand name. At the DRUPA, Heidelberg is presenting its new Nexpress digital colour printer, which has been developed in conjunction with Kodak.

Digital printing is an important new part of the market. Although it’s still relatively small, it is growing at 20 percent a year, compared to the 3 to 4 percent growth in the offset market. The advantages of digital printing are speed and flexibility, as well as relatively low cost on shorter print runs. But quality is not as high as on an offset machine, and long print runs are prohibitively expensive. Still, Dalton sees a new market opening up as a result of digital printing. “If you were trying to sell a high-value house, you used to produce a photocopied piece of paper with a blurred photo on it,” he says. “Now you can produce a brochure with colour pictures. People’s expectations have changed as a result of digital printing.” You can produce big-run catalogues on the offset machine and a personalised page on the digital printer. You can make every computer manual fit the precise specifications of each computer. If you order a Mercedes from a certain car dealer in Hamburg, he sends you the next day a brochure showing your car with all its features. And there’s “printing-on-demand,” where out-of-print or minority-interest books can be printed while you wait in the bookshop. “People used to think that digital would steal market share from offset, and perhaps it has done a bit,” Dalton says. “But mostly it’s created a huge new market.”

The challenges of new technology and new markets may be where Heidelberg’s future lies, but printers can be overwhelmed by the speed of change. That’s where Heidelberg’s new Print Media Academy comes in. Its strikingly transparent building is the first thing you see as you come out of Heidelberg’s main railway station, and it epitomises the change at Heidelberg. At the academy, people from the printing and publishing industry can be trained in every aspect of the business, right up to MBA level. It’s a clear sign of Heidelberg’s move from being a product-driven to being a customer-driven company.

Michael Lawton

a journalist based in Köln

photos Heidelberg