Providing a good foundation for machines

A recently formed SKF Alignment Competence Centre helps customers make proper alignment to prevent early machine failure.

Machinery mounting, alignment services and mounting solutions have become a group focus following the acquisition in 2000 of Dutch specialist Machine Support BV.

Large, complex machines need to be installed on foundations that not only support the machines but also allow them to operate properly. Machine Support has a dedicated engineering service organisation that has been in operation for more than 20 years. At present the group comprises three companies with a wide network of distributors. The headquarters are in Ridderkerk, near Rotterdam, in the Netherlands.

Machine Support forms an Alignment Competence Centre within SKF Reliability Systems. The aim is to provide alignment expertise to a growing customer base around the world. Alignment applications range from paper and steel mills, diesel engines and turbines to generators, pumps, compressors and shaft lines.

A main cause of machinery failure is improper alignment. Generally, misalignment is caused by inadequate measurement techniques, an improper foundation and/or degradation of the foundation.

Range of services

With such a wide range of alignment services, experience of different machinery applications is vital. It is also important to have a range of support designs and accurate measuring systems to make sure that installations are properly sited and mounted. This is necessary for the machines to be stable and, for example, able to cope with appropriate levels of force and vibration without the foundations shaking loose.

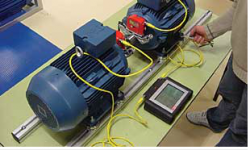

Laser shaft alignment, specialised geometrical alignment and alignment using dial indicators are all techniques that can be applied to mounting applications. The use of lasers has simplified many alignment tasks, but geometrical alignments remain a specialist’s preserve. This type of alignment is suitable for applications such as measuring the straightness of an engine rail, the flatness of a foundation, the line bore of main journals and the parallelism of paper mill rollers. Dial indicators tend to be used in extremely narrow situations, if there is limited space to use laser technology.

Correct installation not only means good product quality but often reduced energy consumption as well, whether it is for the alignment of paper machines, turbines, or process pumps. The use of advanced laser alignment equipment provides high standards of accuracy that are achieved in a short amount of time.

In addition to on-shore equipment, Machine Support is a specialist in marine applications, such as erection, alignment and mounting of both main propulsion units and auxiliary equipment. Besides this, projects have included the installation of propeller shafts, gearboxes, other onboard machinery, on-site machining, 3D measurement, mounting of the main engine, bolt calculations, providing the plan approval certificate from a classification society, etc. In the past two years the company has provided alignment for complete water-jet propulsion installations. This was done, for example, on navy vessels and luxury yachts.

Another area for Machine Support is the wind-power industry, where the company has received an increasing number of orders during the past two years. These orders include geometrical measurements of tower sections and alignment services.

Mounting chocks

The company has developed a range of products that are used alongside measurement techniques to provide proper mounting.

They include:

- Vibracon® SM – an adjustable, self-levelling and reusable chock;

- Epocast 36® for confined space installations (distributor); and

- Steelshim® shim kits.

Vibracon SM mounting elements are permanent, strong and reusable machinery-mounting chocks for all types of rotating or critically aligned equipment. Vibracon mounts are mechanically stiff, which makes accurate alignment simple and quick.

This mounting product has been successfully used for nearly 15 years. It is an economical way to establish a mounting plane. The mounting plane is that area where the equipment interfaces with its foundation. This area can be created in a variety of ways, including machining, shimming and pouring. The advantages of Vibracon are that there is no cure time as with a poured chock and no trial and error alignment characteristic of the mill and shim process. In addition, Vibracon is reusable for the life cycle of the machine. These advantages make Vibracon suitable for production lines and also for pipelines and shaft lines.

Vibracon has many conurations and material options to suit the end-user environment and production-line cost. All Vibracon elements include the spherical top plate and mating middle section. This self-levelling conuration accommodates the angular differences that are inherent with mounting surfaces. Vibracon SM elements accommodate 4 degrees of angular difference between machines and the mounting base without expensive machining of the base or the extra work of epoxy resins.

The capability of self-levelling combined with the height adjustment feature prevents the possibility of equipment “soft foot” in the production line and for the life cycle of the machinery. The height adjustment feature makes Vibracon® SM easy to install.

Vibracon SM elements have received approval from classification societies, equipment manufacturers and military applications with Grade A shock installations. Engineering support for specific needs, non-standard applications or installation training is available.

Recently the company introduced the Vibracon SM Low Profile. The Low Profile elements are an economic solution for repair projects or fixed design systems where expensive milled chocks, shims or epoxy resins were inserted. The Vibracon SM Low Profile conuration addresses applications where the foundation to component chocking height has been established by previous design or chocking methods. Those other chocking methods are time-consuming and do not support the life-cycle needs of the machine owners and installation activities on a tight schedule.

Mounting kit

The Vibracon SM mounting kit consists of all the necessary items for mounting equipment quickly and according to the standards of classification societies. Besides a Vibracon SM element, the set includes foundation and fitting bolts, nuts and spherical washers. The plan approval certificate of the relevant classification society is also included in this mounting kit. Optional items in the mounting kit are Rotabolts®, for accurate bolt load monitoring. In addition Machine Support can offer on-site machining of foundations.

A machine installation specialist Machine Support provides a wide range of dedicated products and services, including:

- Alignment, chocking and securing of diesel engines, turbines, gearboxes, generators, E-motors, pumps, bearings, rudders and winches

- Chocking with universal adjustable Vibracon® SM elements or Epocast 36®

- Alignment and mounting of stern tubes and installation with pourable epoxy resin

- Line bore measurements on diesel engines, compressors and steam turbines

- Measuring the perpendicularity of rudder installations

- Measuring the straightness of shafts

- Alignment of paper, board and printing machines

- Alignment of rolling mill stands

- Geometrical measurements such as straightness, flatness, levelling, line bore, perpendicularity and parallelity

- Erection and measurement of machine tools

- Installation support

- On-site machining and bolt tensioning

- 3D measurement.

Contact Machine Support in Ridderkerk, The Netherlands: +31-(0)180-483828.