TX-Line spherical plain bearings for maintenance-free operation

A new generation of spherical plain bearings and rod ends is bringing new levels of performance in a broad range of application areas.

SKF is introducing a new generation of PTFE-fabric lined bearings. The TX-Line bearings show superior performance to the previous plain bearing design and will thus replace it.

The TX-Line spherical plain bearings ( .1) are designed to support heavier loads for longer or the same load for even longer. It fits perfectly into SKF’s ambition to provide maintenance-free products and solutions to their customers.

The bearing application areas are quite broad and cover almost all industrial segments, such as material handling, fluid machinery, construction and agricultural machinery and automotive industries.

Basically, the new TX-Line is suitable where the user requires:

- Maintenance-free operation;

- Heavy loads at low oscillation motion;

- Reliable, noiseless operation at constant friction; and/or

- The self-aligning ability of a spherical plain bearing.

When developing these bearings, special efforts have been taken to satisfy the ever-increasing demands from the market in terms of:

- Heavier loads;

- Longer service life; and

- Better performance in tough environments.

After analysing the various influences on bearing performance, SKF not only benchmarked and specified new material supplies, but it also studied and redesigned the complicated manufacturing process. After intensive testing on tribological test rigs, the final specification could be set. The results were convincing. On average, the service life could be improved by a remarkable 45 %, compared with the previous design at the reference test point.

Features and characteristics

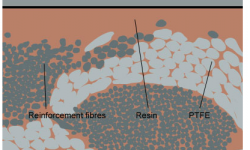

The key design features are the optimised PTFE-fabric liner ( . 2) and strong seals. The liner material is one of the most important structures within a fabric line spherical plain bearing. It has to cope with huge dynamic and static loads, while at the same time taking over the role of the lubricant in-between the rings. The main requirements towards a high-performing sliding material are, therefore, its mechanical strength (against thrust and shear stresses) combined with best-possible wear resistance and a minimum of friction.

The PTFE-fabric liner used is a self-lubricating composite fibre material, which incorporates a new type of resin as a binder. This material makes the bearings stronger than their predecessors. Consequently, the new PTFE-fabric liner and resin system delivers better performance in terms of higher wear resistance/ longer service life coupled with a higher load-carrying capability/higher load ratings.

Special care is taken during the pre-treatment of the hardened rings supporting the liner. Absolute cleanness and a suitable roughness of the substrate, along with the right parameters at the bonding process are mandatory to achieve a high-quality adhesion. Overall, this liner has a three times better adhesion than the previous fabric-liner material.

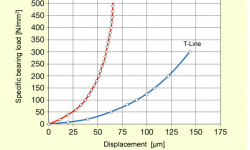

In addition, the bearings have a stiffer spring characteristic, fewer settings under load, reduced clearance and higher reliability when used in humid environment due to the improved bonding. The friction behaviour of the liner is excellent with hardly any variations over the lifetime (at constant load level) and no signs of stick-slip, which is a disturbing friction effect in a sliding contact.

The bearing is available in two different steels, carbon chromium bearing steel and stainless steel, so giving equipment designers the opportunity to more closely tailor the bearing to the application conditions. Stainless steel, for example, is better suited to difficult working conditions or corrosive environments, in respect to total costs or the service life of a machine.

In the range between 25 to 120 mm bore diameter, the TX-Line spherical plain bearings come with integrated, high-performing 2LS seals. These seals have been specifically developed for use in heavy-duty steel-on-steel spherical plain bearings. Their characteristics also match the needs of the premium TX-Line bearings to offer the best protection in difficult environments.

The LS seal has three sealing lips, which exert a higher pressure on the counterface on the inner ring compared with the previous design. Consequently, the new heavy-duty seal 2LS delivers better performance in terms of sealing and protection against the entrance of abrasive material. The new seal also has good water resistance.

A powerful range

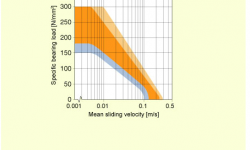

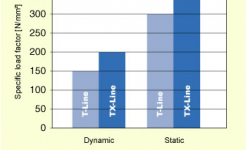

Due to improved dynamic and static stability of the liner, SKF is able to raise the load ratings. The new specific load factors are K = 300 N/mm² and Ko = 500 N/mm² ( . 3).

Furthermore, the permissible operating range of the TX-Line bearings could be enhanced in order to match their performance. The permissible operating range is given as a function of specific bearing load (pressure “p”) and mean sliding velocity (v). These two parameters mainly influence the service life of plain bearings.

. 4is showing the pv-diagram with the enlarged operation range. Compared with the previous design, the bearings can now be operated at demanding “pv” combinations, which has not been possible before.

SKF has also modified the service life formula for TX PTFE-fabric bearings to take into account their enhanced performance. The life formula, along with other bearing selection criteria, will be published in a separate product brochure (SKF publication 5325 E). The new series will also be included in SKF’s Interactive Engineering Catalogue, where the selection of the bearing size can easily be made online.

The standard assortment of TX-Line radial spherical plain bearings ranges from 12 to 300 mm bore diameter. Larger bearing sizes and other bearing types such as angular contact and thrust spherical plain bearings are available upon request. When it comes to rod ends, there are seven bore sizes with both female and male thread available. Read more in publication 5325 E for the TX-Line series.

Real applications

The new TX-Line bearings are well accepted by OE-customers and aftermarkets. For instance, a leading manufacturer of construction machinery accepted the new bearings for use in hydraulic cylinders for telescopic handlers without any further proof or testing. The company appreciated the higher performance level and the validation efforts SKF undertook. In particular, this customer welcomed the introduction of the heavy-duty 2LS seals as new standard for these bearings.

A typical application field where customers have an urgent need for maintenance-free operation is the growing wind power industry. One of the major players is using individual blade regulation, thus taking benefit of the different wind velocities during rotation. Each blade can be steered with an angularity of – 5 ° to 90 ° by means of hydraulic cylinders. These cylinders are equipped with SKF PTFE-fabric spherical plain bearings situated at the end of the rods. They have been chosen in order to cope with the oscillating motion over the long operational life.

For the trunnions of the cylinders, another maintenance-free plain product, SKF Filament Wound bushings, are used. Due to their high load-carrying capability, the width of the trunnions could be reduced. In this case it is clear that the customer put emphasis on reliable, maintenance-free products for these difficult-to-access bearing locations. For the use at offshore wind parks, PTFE-fabric spherical plain bearings with stainless steel rings have been specified.

In a truck application, a SKF spherical plain bearing has been incorporated into V-stays for rear axles. As operational loads have increased over the years, other types of joints with plastic outer rings from competitors are unable to cope with these increased loads. The centre of the V-stay plays an important role in rear axle truck suspensions, because it has to handle high dynamic forces while providing the pivot point for the chassis with full tilting and rotating capability.

In this design, the plain bearing has to be able to handle shock loads of up to 160 kN without any noise and with low wear characteristics. Prior to the application being accepted by the customer, the bearing performance was validated through testing on a three-dimensional dynamic test rig, in addition to road field tests.

In a different vehicle application, SKF spherical plain bearings have been used in refuse trucks. They are part of the system employed in the filling and compressing of garbage (waste) in the back area of refuse vehicles. In this application, two plates (carrier and press plates) are installed, which transport the waste into the compression area. Afterwards the press plate compresses the garbage. Both plates are arranged with SKF spherical plain bearings.

The carrier plates are equipped with heavy-duty bearings GE 70 ESL-2LS. The bearings work in a literally contaminated environment (dirt, liquids, waste). These bearings are manually relubricated in certain intervals. They feature the integrated multi-groove lubrication system designed for a better grease supply of the loaded bearing zone together with a better grease storage and 2LS seals for an improved bearing protection.

The press plate is situated in an upper position where the working conditions are not as demanding as for the carrier plate bearings. For this position,maintenance-free bearings GE 50 TXE-2LS are suitable. Up to now, maintenance-free competitor bearings did not give satisfactorily results. The SKF’s products are working well, achieving a significant increase in service life.

Extensive testing

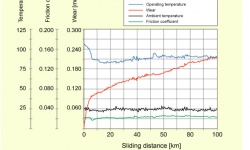

The new TX-Line bearings have undergone extensive testing prior to serial approval. Of main interest has been performance in terms of achievable sliding distance or number of oscillations. Heavy constant and reversing loads were chosen in order to investigate their tribological behaviour. The measured parameters were excellent: a constant low friction coefficient, safe bearing temperature and a low wear rate leading to a long service life ( .5).

In order to test the quality of the bonding, tear-off forces were measured after the test specimens were stored for a month in air or under water. The differences between air and water storage were minimal and the tear-off forces were improved by a factor of three, relative to the previous materials.

When measuring the spring characteristics of the bonded new fabric-resin system, it turned out that it was stiffer by far than its predessor. In practice, this means fewer settings under load, and thus a reduced increase in internal bearing clearance ( .6).

The efficiency of the 2LS seal has been tested on a contamination test rig where a mixture of specified abrasive particles and water was applied on the oscillating bearing. Compared with ordinary seals, the heavy-duty seals showed at least a four times higher sealing performance.

In addition, field tests have been carried out with dedicated customers. This has confirmed that the TX-Line range represents a considerable improvement in spherical plain bearing design across a wide application range.