Smart Housing – the integrated sensor solution

Smart Housing is a way of integrating sensors into a housing to allow monitoring and control of critical bearing applications. It is a robust system that can track the performance of a particular machine or process.

Customers need to monitor and control critical parameters, because these are the keys to reliable operation. Condition monitoring has the objective of improving production reliability, increasing safety and gaining more knowledge about an application. Production reliability provides shorter and fewer planned production stops and fewer unplanned stops, meaning higher production efficiency and a predictable production. Increased safety means early warnings to avoid breakdowns and hazardous situations. Increased application knowledge enables analysis of root causes of failures that cause production stops, facilitating a process to improve operations. With increasingly complex processes, process control is becoming more and more important in the industrial world, and Smart Housing provides some of the necessary input.

Traditional monitoring of machines and processes has often resulted in external instrumentation and sensors being installed around the application. This “Christmas tree” approach has a number of inherent disadvantages, such as susceptibility to vibration and the need for additional protection or shielding in order to operate effectively.

Built-in sensors

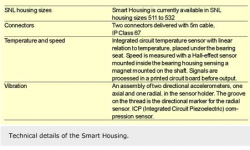

For bearing applications, SKF has developed its Smart Housing concept, where all the sensors are integrated in the housing. Signals from the sensors are processed in a printed circuit board (PCB) to provide a more robust output signal that is resistant to interference. The PCB also has power surge protection circuitry to shield the sensors from anomalies in the power supply signal. The sensors and the PCB are integrated into the bottom cavity of the SNL housing, and signals from the sensors are carried through two connectors mounted on the front of the housing that are ready for connection to condition monitoring systems. This makes it easy to install and quick to put into operation.

Customer needs

From interviews with OEM and end-user customers in the fan and conveyor industries, it has been found that rotational speed, temperature and vibration were the most important parameters to measure. The Smart Housing, developed by SKF, therefore has a modular two-connector layout. The first connector delivers temperature and speed data, while the second connector supplies two vibration signals. Vibration monitoring relates to axial vibration and an adjustable radial vibration. A specially designed integrated sensor holder delivers these signals to the connector. The sensor holder can be rotated in its position in the housing, allowing the adjustable vibration measurement to be set to external disturbing sources in the application or to a directly radial position to measure the bearing radial vibration.

Three possible set-ups can be delivered:

- temperature and speed;

- axial and adjustable (radial) vibration; or

- temperature, speed, axial and adjustable (radial) vibration.

Smart Housing is already making a contribution to improving customer applications and gaining greater insights into a particular machine or process. For example, Smart Housing has been installed in an upgrade of a conveyer at Arundel Stone Corp, a subsidiary of Florida Rock Industries Inc. situated in Havre de Grace, Maryland, in the United States. Florida Rock is a major US basic construction materials company and is one of the biggest producers of construction aggregates (sand, gravel and crushed stone), ready-mixed concrete, concrete blocks, Portland cement and prestressed concrete.

The Smart Housing unit is mounted on the tail pulley of the main conveyor that transports crushed limestone from the quarry to barges on the Susquehanna River. From the barges, the crushed stone is shipped along the east coast of the US. The reason for the upgrade of the conveyer system was to improve the loading rate of material onto the barges. The speed signal, delivered from the Smart Housing, will confirm that the pulley is rotating and how the conveyor belt is operating. The pulley will stop rotating if the conveyor belt is broken or jammed. Without a speed signal, the plant operator and automation system would not know that a conveyor belt fault exists, and this can lead to a costly spill of material and damage to the equipment. Temperature monitoring warns of overheating, while vibration monitoring gives information on bearing damage and loosened components.

More potential

Fans are another major potential application for the Smart Housing. For example, a Smart Housing installation on a fan gives an early warning for imbalance caused by dirt on the fan blades. Imbalance will generate vibrations that can eventually cause a fan breakdown. Vibrations from external sources are effectively detected through the adjustable radial accelerometer that can be set in the optimal direction for each application. The speed signal can be used to regulate the fan power consumption.

Other examples of critical fans can be found in the mining industry, where fans supply the interior of the mine with fresh air. Production will halt if the fans fail, since air-quality problems will keep anyone from entering the mine. Other critical fan applications are those in processes where the fan is an integral part, such as drying or moving products.

Industrial washing machines are another potential application area. These machines are subject to considerable variations in vibration, depending on the wash load. During the spin cycle, problems may occur if the laundry is unevenly distributed in the drum, resulting in excessive vibration levels. Unless the laundry is redistributed inside the drum, the spin cycle speed will not be able to reach the required level. The number of revolutions and the speed determine the amount of water that will be removed from the laundry, and hence the quality of the wash and the subsequent drying time. Monitoring vibration and speed gives the necessary input for the process control. The temperature measurement also gives an indication of overload.

Designed for integration

Smart Housing is designed for integration with condition monitoring solutions that are already available within SKF as well as third party or customer specific solutions for both monitoring and control. This allows for full flexibility, from a complete condition-monitoring solution to an offer with a Smart Housing that is integrated into a control system already in place at a site or a built-in solution.

Finally, Smart Housing is a new tool in the SKF toolbox that offers a robust integrated solution for customers who want to monitor and control critical applications. With this standardised system, SKF can offer its customers a quick start-up and easy installation coupled with reliable monitoring and control solution.