Benefits of using black oxidized bearings in wind applications

The ever-increasing size of wind turbines to generate more power is placing higher demands on the drivetrains.

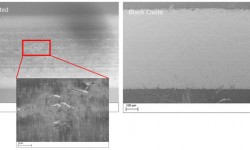

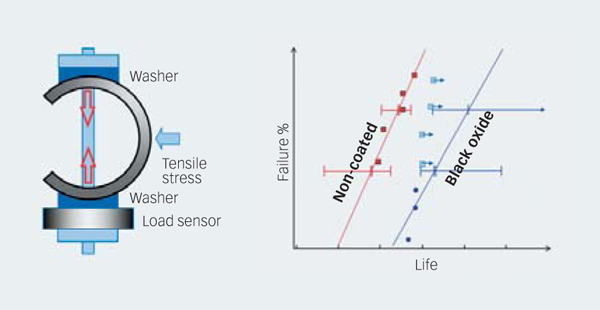

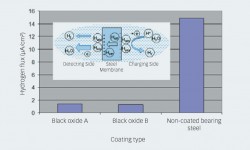

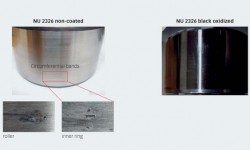

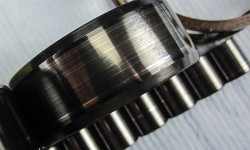

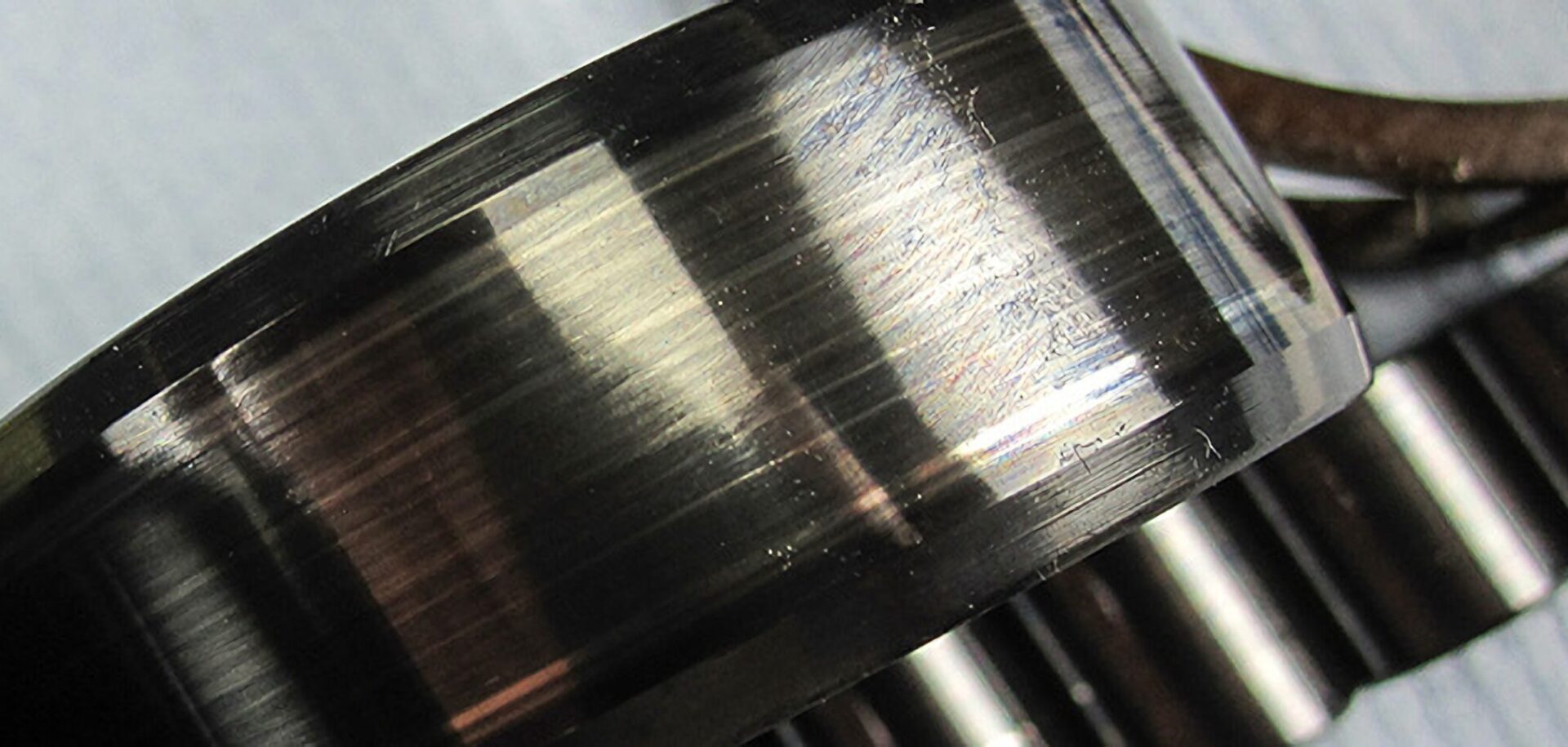

One of the requirements to prevent these failures is superior surface performance that favours the running-in process, is resistant to corrosion and is inert against unfavourable reactions from aggressive lubricant chemistry. Through SKF’s long involvement with the wind energy industry, the company has identified black oxidation as one of many solutions to improve operational reliability. Black oxide is a surface treatment that is formed by a chemical reaction at the surface layer of the bearing steel and is produced when parts are immersed in an alkaline aqueous salt solution operating at a temperature between approximately 130 and 150 °C. The reaction between the iron of the ferrous alloy and the reagents produces an oxide layer on the outer layer of the bearing components, consisting of a well-defined blend of FeO, Fe2O3 and resulting Fe3O4. The result is a dark-black surface layer of approximately 1–2 μm in thickness. The total process consists of about 15 different immersion steps, in many of which it is possible to vary chemical contents, concentrations, temperatures, immersion times and fluid behaviour within the tanks [3]. Only the most relevant beneficial effects of black oxidation to the wind industry are summarized here. They are briefly described by three categories and demonstrate how black oxidation can help in reducing the risks following each failure mechanism. In some wind turbine drivetrains, wind gearbox bearings may fail prematurely due to cracks, spalls or irregular white etching cracks (WECs). WEC refers to the appearance of the altered steel microstructure when polishing and etching a microsection. Failures can be found at several bearing locations in wind gearbox design, such as the planet bearings, intermediate shaft and high-speed shaft bearings. The occurrence of failures due to WEC is widely discussed within the wind industry and is being independently investigated by wind turbine manufacturers, gearbox manufacturers and bearing suppliers as well as universities and independent institutes. Many of the current hypotheses are focused on surface-related issues, such as hydrogen penetration and inter-action with subsurface inclusions or purely stress/tribomechanical developments related to the surface operation. For further information about WEC failure root cause hypotheses refer to [4]. According to ongoing investigations and information from literature, different mechanisms can contribute in reducing the risk for WEC failures, such as: Black oxidation can contribute to protect the bearing components from the aforementioned failure mechanism. In the following, several laboratory tests and investigations reveal the advantages of black oxidation. 1.1 Tribochemical attacks from lubricant and additives Gear oils are developed to optimize gear performance. In most cases, anti-wear additives and corrosion inhibitors are added to gear oil to boost gear performance. Unfortunately, gear oil chemistry does not always favour rolling bearing operation. In gear tooth contacts, the macroscopic sliding is significantly greater (slide-to-roll ratio up to 30 %) than in bearings (slide-to-roll ratio up to 4 %, depending on the bearing type). Therefore, the dynamics (formation and removal) of reaction layers in gears are different from those in bearings. When bearings operate in marginal (boundary and mixed) lubrication conditions, reactions happen between the additives in the gear oil and the steel surface in rolling contacts. Chemical energy exerted during the formation of a reaction layer together with the tribological energy likely changes the near-surface microstructure of the bearing steel [9]. The change of the near-surface microstructure leads to the change in the mechan-ical properties of the surface and consequently the tribological performance (friction, wear and surface fatigue). If the reactions are unfavourable, then significant near-surface microstructure changes happen, followed by the initiation of surface microcracking. Testing gear oils, Pasaribu and Lugt [10] have shown the positive correlation between the thickness of oxide layers and bearing performance. This indicates that the passivation of bearing surfaces retards unfavourable reactions between gear oils and bearing surfaces. Therefore, pre-prepared ~1-2 μm oxide layers such as a black oxide layer reduce the risk of the unfavourable reaction between gear oils and bearing surfaces. The advantage of the black oxidation treatment in preventing surface crack formation can be assessed by subjecting the black oxidized surfaces to boundary-lubricated tribological contacts. An example of such a test is the skewed lubricated ball on disc. The ball and the disc are independently driven, allowing the control of slip-to-roll ratio that is relevant to bearing operation. Fig. 2 shows results of tests with oil containing aggressive anti-wear additives. The untreated steel surface suffers from surface micro cracks, while the black oxidized surface does not show any formation of surface micro cracks. 1.2 Hydrogen embrittlement Black oxidation, as a surface “passivation” treatment, can effectively reduce the ingress of atomic hydrogen and chemical attack to bearing steel. This property was evaluated in the lab test results of C-ring and H-permeation tests [11]. A specially designed C-ring test rig was developed for evaluating hydrogen-induced stress corrosion cracking (HISCC) in lubricated contacts [12]. Fig. 3 shows an inner ring of a cylindrical roller bearing with a cut-out segment. The ring is loaded via a screw to generate a defined tensile stress on the surface. Surface-initiated cracks under tensile stress are promoted by hydrogen uptake from the lubricating environment. C-ring life, defined as the time until the C-ring is cracked under defined tensile load, is reflecting the resistance against HISCC. The graph in fig. 3 shows that black oxidized C-rings have longer lives compared with the non-coated specimens. The resistance of black oxidation to hydrogen uptake can also be evaluated in an electrochem-ical H-permeation test, in which atomic hydrogen is generated by electrochemical charging. The hydrogen permeates through the steel plate and is measured by electrochemical oxidation when being liberated from another side of the steel plate. The hydrogen ingress through a surface coating can be evaluated by comparing the obtained hydrogen permeation flux (current) with that from the non-coated specimen. Fig. 4 shows that steel plates with a black oxidized surface give significantly lower H-permeation flux than the non-coated specimen. This is because, different from diffusing in bulk steel, atomic hydrogen must be ionized (as proton) in order to pass through an oxide layer. The strong interaction between ionized hydrogen atoms and anions in iron oxide makes a black oxide layer acting as a barrier that decelerates H-permeation [13]. 1.3 Moisture corrosion damage (standstill corrosion) Large temperature gradients promote condensation of water from the humid air. Although the risk of water contamination is not often directly mentioned for wind applications, it has been well known that dissolved water could reduce the functionality of anti-wear additives [14] and that free water promotes corrosion and hydrogen uptake [15][16]. The corrosion risk becomes higher when standstill is encountered during the wind turbine main-tenance interval or the absence of wind [7]. The microstructure of black oxide has a certain porosity, which can increase the affinity of the lubricant or preservatives onto the coating layer and improve the resistance to moisture or standstill corrosion. In a salt spray cabinet test [17], black oxidized specimens did show significantly higher corrosion resistance compared with non-coated specimens (fig. 5). 2.1 Adhesive wear; smearing or slip damage If roller bearings are too lightly loaded (below required minimum load), it can lead to a considerable mismatch between the rotational speeds of inner ring and roller set, which in turn leads to high sliding between rolling elements and inner ring [18]. For demanding applications such as wind gearbox high-speed shafts, idling conditions and load zone changes can sometimes lead to high sliding conditions. Consequently, there is a high risk of smearing damage [19] [20]. Wind gearbox idling test results have shown an improved protective effect of black oxide coating against smearing damage in high-speed shaft bearings. Fig. 6 shows smearing damage that appeared on the non-coated roller and inner ring surfaces after 45 minutes of idling operating conditions, while black oxidized rings have shown no significant damage after 30 hours. The protective mechanism of the black oxidized surfaces can be explained by a reduced friction after running-in, as well as the improved adhesion of the lubricant to the surface compared with non-coated surfaces. 2.2 Surface distress Surface distress is a surface-initiated fatigue at an asperity level associated with poor lubrication conditions, corresponding to high surface (frictional) tractions [21]. It occurs especially on gear teeth, but sometimes also on bearings. If it happens to bearings, surface distress can be particularly detrimental to the bearing function. Being not necessarily a primary failure mode for rolling bearings, it can facilitate or accelerate the appearance of other failure modes such as debris indentations, surface-initiated spalling and seizure [22]. The risk of surface distress can be reduced by several means, for instance, by lowering the surface friction, redistributing the near-surface stresses in a favourable way or reducing the mixed-lubrication pressures or optimizing the running-in process. One way to realize this scenario is to use protective coatings, such as black oxidation. Despite the large amount of theoretical and experimental work on surface distress in general (see e.g. literature review in [21]), the influence of coatings on surface distress has not been sufficiently studied so far. Therefore, a series of experiments with black oxidized rollers was performed [23] on a surface distress test rig under laboratory conditions [14] [21], which imply controlled slide-to-roll ratio, lubrication conditions, temperature, load and speed. The load unit of the surface distress test rig is schematically shown in fig. 7 (top): a rotating roller is in contact with three discs, all made of hardened bearing steel. It consists of a small roller (12 mm diameter) taken from a spherical roller bearing and three larger counter bodies that are cylindrical roller bearing inner rings. The roller and rings can be finished by grinding and/or honing to a desired roughness pattern. The material of tested rollers and counter bodies is ANSI-52100 bearing steel. The lubrication conditions during the tests varied from boundary to mixed lubrication. After the tests, the surface of the rollers was checked for surface distress. Results were compared for non-coated and black oxidized rollers under identical conditions. The experimental results obtained with the surface distress test rig reveal a certain anti-surface distress protection of black oxidation throughout the whole range of the test conditions [23], as depicted in fig. 7. Furthermore, a parametric analysis of the surface distress model [22] was performed for coated surfaces [23], including the effects of friction, coating stiffness and thickness. The existence of optimum coating thickness cor-responding to minimum surface distress damage was found. As shown by both experimental and theoretical results, black oxide treatment extends the range of surface distress-safe operating conditions compared with non-coated bearing steel surfaces. A bearing life test has been carried out with black oxidized bearings at severe mixed lubrication conditions. The positive effect of black oxidized bearings compared with non-coated bearings with respect to running-in [24] and low kappa lubrication conditions could be confirmed. In this test, all black oxidized bearings passed the defined test duration without any failures. Indeed, the results point to an L10 life estimate that is two to three times above the L10 life estimate of non-coated bearings. In addition to the above component test and bearing test results, the benefit of black oxidation in reducing the risk of premature failures is proved by field experience. Reports from gearbox manufacturer and wind turbine OEMs confirm a significant improvement in reducing the bearing failure rate by using black oxidized bearings, compared with non-coated bearings [25] [26]. Furthermore, it has been observed in [8] and [25] that a gentle reheating below the tempering or transformation temperature can help to optimize and reinforce the microstructure without hardness loss and consequently extend the bearing fatigue life. Following this concept, black oxidation at a similar temperature can help to create beneficial microstructural effects within the outer steel surface, which was reflected by a reduction in the full width half maximum value (FWHM or b/B) of the XRD peaks by >0.1 degrees. Several beneficial effects of black oxide have been demonstrated by combining lab investigations, bearing tests and field experience. Black oxide offers a certain protection against tribochemical attack, reduces the permeation of hydrogen and increases the resistance to moisture damage (such as standstill corrosion). Furthermore, black oxidized bearing steel surfaces improve the safety margin, when looking at failure modes such as adhesive wear/smearing damage or surface distress. Positive field experiences underline these findings. To summarize, the black oxidation process used by SKF offers enhanced protection against damage to bearing components. Black oxidation treated bearings can – besides being used in the original equipment – be used as drop-in replacements for conventional bearings as part of wind farm maintenance routines. This means that the benefits of black oxidation can be applied to all bearing types used in key wind turbine gearbox systems across the entire wind energy industry. SKF recommends that both inner and outer rings as well as the rolling elements be black oxidized for optimal performance. Black oxidation process

Benefits of black oxidation

1. Reduced risk of premature failures

2. Severe operating conditions with insufficient lubrication or surface damage

3. Bearing test and field experience

Conclusions