Core competence

In a world that is constantly grasping for more and cleaner energy, the Belgian Nuclear Research Centre has an important mission – to make the world of nuclear physics a safer place.

In a world that is constantly grasping for more and cleaner energy, the Belgian Nuclear Research Centre has an important mission – to make the world of nuclear physics a safer place.

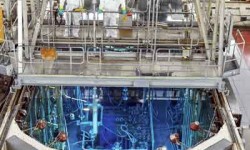

Tucked away behindhigh fences in a forest on the outskirts of the city of Mol, in the northeastern corner of Belgium, is the Belgian Nuclear Research Centre, SCK•CEN. The centre is home to one of the world’s most powerful nuclear testing reactors and a team of dedicated researchers whose goal it is to make the world of nuclear physics a safer place.

Belgium’s nuclear programme dates back to 1944 when the United States government together with Britain struck a deal with the Belgian government over their uranium reserves in the Shinkolobwe mine in the Congo. Belgium agreed to supply uran-ium ore to the allies and give them exclusive rights over these uranium stocks for 10 years, in exchange for access to nuclear expertise for research, commercial and non-military applications. Thus, the Belgium nuclear programme was born, and in 1952 SCK•CEN was founded.

SCK•CEN’s mission is to sustain development by R&D, training, communications and services in order to contribute to nuclear safety and radiation protection, medical and industrial radiation applications and the back end of the nuclear fuel cycle in terms of reprocessing and waste management. Research projects are mainly focused on issues of societal concern, such as reactor and fuel safety, radioactive waste disposal and nuclear decommissioning and radiation protection. The centre also offers a significant contribution to Belgian and European education and training programmes.

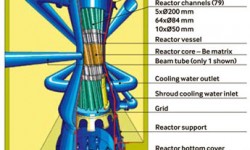

The star in SCK•CEN’s firmament is the BR2 materials testing pressurized water reactor. “BR2 is a high thermal neutron flux reactor with a flux of up to 1015 neutrons per centimetre squared per second, making it the most powerful materials testing reactor in Europe,” says Bernard Coupé, head of Nuclear Instrumentation and Control at SCK•CEN. The BR2 produced its first chain reaction in July 1961 and came into service in January 1963 using uranium (235U) that is highly enriched to 90-93 percent.

The BR2 is not only used for scientific research by the centre’s own departments but is also used to carry out experiments for external clients. “For example, we are currently working on a project to test the safety of some experimental fuels to be used in a new reactor being built at the Cadarache nuclear energy research centre in the south of France near Aix-en-Provence,” explains Coupé. “We’ve been measuring its strength, reactions and longevity, checking how it behaves inside the reactor by submitting it to very high flux.”

But the BR2 has a double mission: In addition to its capacity for experimentation, it is also used for the production of radioisotopes and the neutron transmutation doping of silicon. “Some 30 percent of our budget comes from the state, but the reactor isn’t necessarily profitable as a research facility,” says Coupé. “The income we receive from these commercial operations pays for part of our operations.”

“The BR2 reactor is a major facility for the production of radioisotopes that are used for medical, industrial and research applications,” says Bernard Ponsard, project manager for radioisotopes and ASC silicon. “There are six high-flux reactors in the world, and BR2 is the only one in Europe able to produce particular isotopes such as tungsten-188 (W-188) for the manufacture of tungsten-188/rhenium-188 generators for therapeutic applications. Along with other European research reactors, BR2 offers a large irradiation capacity for commercial activities worldwide.”

The most importantof the produced radioisotopes is a fission product, molybdenum-99, which is used to manufacture molybdenum-99/technetium-99m generators. “Technetium-99m is used in 80 percent of all medical radiodiagnostic procedures but has a half-life of just six hours, so a continuous supply is essential,” says Ponsard. “We have agreements with other reactors to harmonize our operating schedules so that we can ensure this service.

“We also produce a wide range of radioisotopes such as samarium-153, rhenium-186 and lutetium-177, which are used for treating cancers, as well as iridium-192 (Ir-192), which is used for radiating small tumours,” Ponsard continues. “The production of these isotopes for medical treatment accounts for the majority of our commercial activity.”

Ir-192 is also produced for industrial applications. It is used around the world for gamagraphy tests, to check the strength of industrial welds. “We also produce other elements, such as mercury Hg-203, which is a tracer for checking the homogeneity of chemical processes,” explains Ponsard.

The third application for radioisotopes is research. “We are sometimes approached by researchers to produce exotic radionuclides such as neodymium-147, which is a radiotracer,” says Ponsard. The centre also helps out with academic research, recently supplying the University of Antwerp, Belgium, with copper-67 that was used in a research application to find out how fish assimilate certain heavy metals in polluted water.

Another significant revenue stream is silicon doping for clients in the electronics industry, mostly based in Japan. “We irradiate ingots of silicon inside the reactor to change their resistivity,” says Ponsard. The customers then slice them into two-millimetre sections, which are photographically etched and then soldered inside electronic equipment.” (See article starting on page 7).

The centre processedsome five tonnes of silicon in 2007. “Right now, we can handle silicon ingots up to five inches [127 millimetres] in diameter, but in 2008 a new project named POSEIDON will increase this to eight inches [202 millimetres] and thus significantly jack up our annual capacity, which will contribute to the justification of a sixth annual operating period for the reactor,” says Ponsard. BR2 currently runs for five 21-day cycles each year, with the rest of the time being used for essential maintenance operations, loading and unloading the reactor and preparing new experiments.

Aside from the BR2, SCK•CEN’s other facilities include the BR1, a graphite-moderated, air-cooled reactor used as a neutron source for activation analysis, dosimetry calibration, neutrography and reference reactor experiments, the VENUS zero-power critical facility for analysis of reactor core configurations and HADES, an underground lab for studying nuclear waste storage. But as the number of high-flux research reactors in the world declines, the BR2 is becoming increasingly more important. Says Ponsard: “BR2’s irradiation possibilities are such that it’s the Rolls-Royce of reactors.”

Fast reaction

The central reactor section in the BR2 is a beryllium matrix of 79 hexagonal irradiation channels containing fuel elem-ents, cadmium control rods and experiments or devices for commercial activities such as radioisotopes production and silicon doping.

Because they absorb neutrons, the cadmium rods control the neutron flux and the reactivity inside the reactor core. The control rods move up and down inside the reactor using stainless-steel SKF roller screws. These screws undergo a special coating treatment to prolong their life and have a minimum expected service life of 10 years.

If there is a sudden increase in flux, the excess neutrons are absorbed by

the control rods, and they drop to the bottom of the core, stopping the reaction immediately. It takes 10 milliseconds to trigger this reaction, and the rods drop 250 millimetres in less than 200 milliseconds.