Flexible solutions with angular contact ball bearings

The automotive industry is a major bearing user, a fact that is reflected in the extensive range of special bearings that have been designed to meet the unique requirements of vehicle manufacturing.Angular contact ball bearings, in particular, have many roles to play in this industry. Considered a “multi-purpose” design, these bearings have the ability to accommodate combined loads, high speed and low noise operation. Other characteristics of these bearings are high running speed and acceleration, high load carrying capacity, different clearance or preload classes and the fact they are available with a variety of cage materials.

The automotive industry is a major bearing user, a fact that is reflected in the extensive range of special bearings that have been designed to meet the unique requirements of vehicle manufacturing.Angular contact ball bearings, in particular, have many roles to play in this industry. Considered a “multi-purpose” design, these bearings have the ability to accommodate combined loads, high speed and low noise operation. Other characteristics of these bearings are high running speed and acceleration, high load carrying capacity, different clearance or preload classes and the fact they are available with a variety of cage materials.

The most common types of angular contact ball bearings are, single row, double row and four-point contact. Such ball bearing designs are available in standard types and sizes but can also be tailored to special applications. In the automotive sector, customised designs are needed to meet evolving goals of reduced weight, space limitation, integration of components and systems, matching surrounding components, easy mounting, low maintenance and lower overall cost.

In particular, the various characteristics of angular contact ball bearings provide a good base for developing solutions for clutches, steering arrangements, engines and gearboxes.

Flexible options

For each bearing design, there is a choice of different cage materials, such as polyamide, machined brass, pressed steel or brass, or special materials, including light alloy. The bearing rings can be tailored to allow optimisation of the design in terms of function, space or weight. Design features such as flanges, notches or additional components like snap rings can be added to the bearing to simplify the mounting procedure.

For maintenance-free solutions, there is an increasing demand for sealed and greased bearing designs. Angular contact ball bearings allow the application of shields and seals. A number of greases can also be used with this design to optimise performance. For reasons of availability and to minimise tooling costs, the integration of existing components of bearings are used where possible. In some cases, customised solutions have to be applied, such as clutch release bearings mainly used in truck applications.

The design of single row angular contact ball bearings enables such bearings to be matched into pairs. This is used when the load carrying capacity of a single bearing is insufficient for the particular application or when the bearing arrangement is required to carry axial loads in both directions.

Correct adjustment and care in the choice of operational clearance or preload are important for trouble-free operation. Also the individual selection of the contact angle and the osculation allows the designs with optimised load carrying capacity and bearing stiffness. Osculation is the ratio between the radii of the rolling element and the raceways of the bearing rings.

New solutions

Developments in motor engine design requires novel bearing solutions. Together with the Rover group, for example, special units based on double row angular contact ball bearings were developed. Double row angular contact ball bearings are rather like two single row bearings arranged back-to-back, but they are narrower than two single row bearings. Double row angular contact designs can handle heavy radial loads and axial loads acting in both directions, and are more compact and easier to mount than two single row bearings.

Normally, these bearings are designed with a contact angle of 30° and provide relatively stiff bearing arrangements that can also take up tilting moments.

In this automotive application, the bearings guide the cam shafts and take over the additional functions required for a variable valve control system developed by Rover. The bearing unit is integrated into the whole mechanism of the drive system for the cam shafts. So, beyond all the functional requirements, there is the need for special dimensions to allow the entire mechanism to fit into the limited space allotted to it.

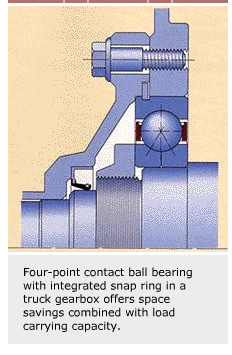

The use of four-point contact ball bearings in gearboxes represents another major application area for angular contact ball bearings. Essentially, this type of bearing is a single row angular contact ball bearing that has a special design to enable axial loads to be accommodated in both directions. They provide high load carrying capacity and require less axial space than double row bearings. A pre-assembled snap ring fitted to the outer ring offers simple axial location as well as easy and quick mounting.

Overall, angular contact ball bearings offer a wide range of possibilities to the automotive industry. SKF has an extensive range of single row, double row, four-point contact ball bearings or special designs that can be used to provide reliable solutions from simple designs to high precision bearings or to systems operating under extreme conditions.

An important aspect of tailoring a design to a particular application effectively and economically is the long-term, close working relationship with the automotive industry.

Werner Palmetshofer,

SKF Österreich AG,

Steyr, Austria