Keeping the right pressure

A new system will manage tyre pressure and temperature, compensating for any abnormality and making the need for spare tyres obsolete. The result: increased mobility, safety and comfort for drivers.

Summary

SKF has developed a special bearing so that the TIPM system can use almost all the existing components in a wheel end system, within the confines of the limited space available. The air bearing resembles a standard wheel bearing, but it has some special features that guide the compressed air flow from the vehicle to the tyre, making it suitable for this application.

The compressed air passes from the outer ring through a well-sealed path between the two rows of balls or rollers. It comes out through the inner ring into the shaft and then into the wheel and tyre itself.

It is critical to have a very good sealing system between the two rows of rollers, so that there is no leakage during inflation. However, at the same time minimum friction must be maintained at the additional sealing system in the centre of the bearing.

Beyond the conventional tests and requirements for wheel bearings, numerous additional tests have been developed by the SKF Car Corner team in Airasca, headed up by Simona Pilone, in conjunction with Michelin and Wabco, to verify performance and leakage levels at different pressures, speeds and time cycles.

If you have ever had a flat tyre while travelling at high speed then you can understand the danger this kind of incident can bring about. But thanks to a new project currently in development, Michelin – along with industry partners SKF, Wabco and TRW Automotive will soon be offering an intelligent system that will monitor tyre pressure and temperature and will compensate automatically for any abnormalities. With this in place, flat tyres will soon be a thing of the past.

“Michelin has always been a leader in tyre pressure management, and for more than 20 years this has been an important research field for us,” explains Pascal Mahier, project manager for Michelin’s Pressure Management Passenger and Light Truck Tyres Division. “But we were lacking the crucial link we needed between the tyre, its pressure and the vehicle.”

Then, along with various partners, including SKF, an idea evolved that would use a bearing as the link through which air passed from chassis to tyre. “We started work on it,” Mahier says, “and in 1992 the first contract was signed between Michelin and SKF on the ‘air bearing’ system.”

The project was under development throughout the mid-1990s, but none of the various on-board system architectures considered presented enough achievement and maturity to get to market at the time. A few years later the situation was different.

“In 2000, after we’d seen the arrival of pneumatic suspension, which had previously been reserved for heavy-goods vehicles, we decided to do something that could be proposed to car manufacturers,” explains Mahier. “But we wanted to bring another partner on board, a leader in the field of compressed air management, so we approached the US-based company Wabco. With them, we signed a joint agreement to develop a complete architecture that would benefit from Michelin’s expertise in air pressure monitoring and Wabco’s experience in compressed air, inflation and on-board architecture, linked with our continuing partnership with SKF.”

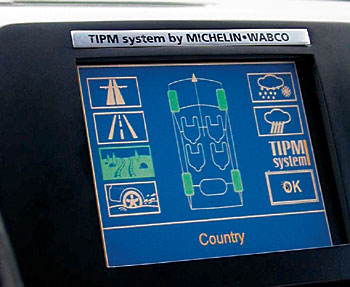

The Tire Intelligent Pressure Management system, or TIPM, addresses four main functions regarding tyre pressure: surveillance, inflation, deflation and information. “We should regularly check our tyres, but we often don’t,” Mahier says. “But this system makes sure it is carried out regularly. It surveys your tyres for you. If there’s anything wrong, it will activate its second function, inflation, which is also normally left to the driver. The same goes for deflation, but because all of these things are done automatically, it is essential that drivers receive information about what the system has done on their behalf, telling them what they need to know and when they need to know it.” Information is displayed via a user-friendly interface on the car’s dashboard.

Increased safety

The TIPM system means less maintenance and increased safety and comfort for the driver and passengers. The driver no longer has to worry about tyre pressure – what it is or what it should be. Each time the vehicle is started, TIPM checks and adjusts tyre pressure to the appropriate level. During the drive, the system monitors pressure and automatically adjusts it, depending on road surface, load and weather conditions. If necessary, the driver can also manually override the system.

“If a puncture occurs, you can drive an unlimited number of kilometres because the system will compensate – it’s like having a puncture without having a puncture,” says Mahier. “Of course there is still a hole, but the TIPM compensates for the loss of air.”

Used in conjunction with Michelin PAX System tyres, safety is even greater. The PAX System tyre is a new breed of tyre with an entirely new wheel and tyre architecture, where it is made sure that the tyre stays on the rim even at zero pressure. If a puncture occurs, the car can continue for 200 kilometres at speeds of up to 80 kilometres an hour, thanks to a supporting inner rim. “The PAX System is there to take over in the case of a sudden blow-out, where it would maintain the mobility and safety of the car,” says Mahier. With these systems in place, a spare would be obsolete.

The surveillance and information functions are maintained by a system that uses a sensor in each tyre that is situated behind the valve. The sensor measures tyre pressure and temperature, sending a message via radio to the on-board computer at regular intervals. For the surveillance system architecture, including the pressure sensor and the receiver, Michelin formed a partnership with TRW Automotive.

Michelin completed this system with the addition of automated inflation and deflation functions, using a pneumatic system supplied by Wabco. The system uses a compressor with an air dryer that sends dry air through a pneumatic network of pipes and valves towards the tyre in question. The air passes through the wheel bearing to inflate or deflate the tyre.

Top end

“Today, our target is the passenger and light truck market segment, but obviously there are certain categories of vehicles that may come first, such as sports and luxury vehicles, as the system is complex and deeply integrated into the vehicle’s architecture,” explains Mahier. “We’ll almost certainly enter the market via the top end, but without any specific constructor in mind. TIPM would be offered as an option at purchase, but we’re not excluding any vehicle and can certainly envisage the system being developed to fit almost any kind of car.”

TIPM is scheduled to enter the European and North American markets by the beginning of 2006, with global rollout of the system to follow. “Currently there’s no real competition on the market,” explains Mahier. “Some existing systems offer pressure compensation within a limited range just to maintain a single level of air pressure, but they haven’t seen much success on our target market.”

For Mahier, TIPM is about joining forces with other experts with the ultimate goal of increasing mobility, safety and comfort for the driver. “We’ve brought together different experts, leaders in their fields – TRW Automotive for the radio frequency, Wabco for air compression management and SKF to provide the bearing expertise. Beyond expertise on pressure monitoring, Michelin takes care of the coordination and piloting of the whole project and will be in contact with end users for promotion and sales.”