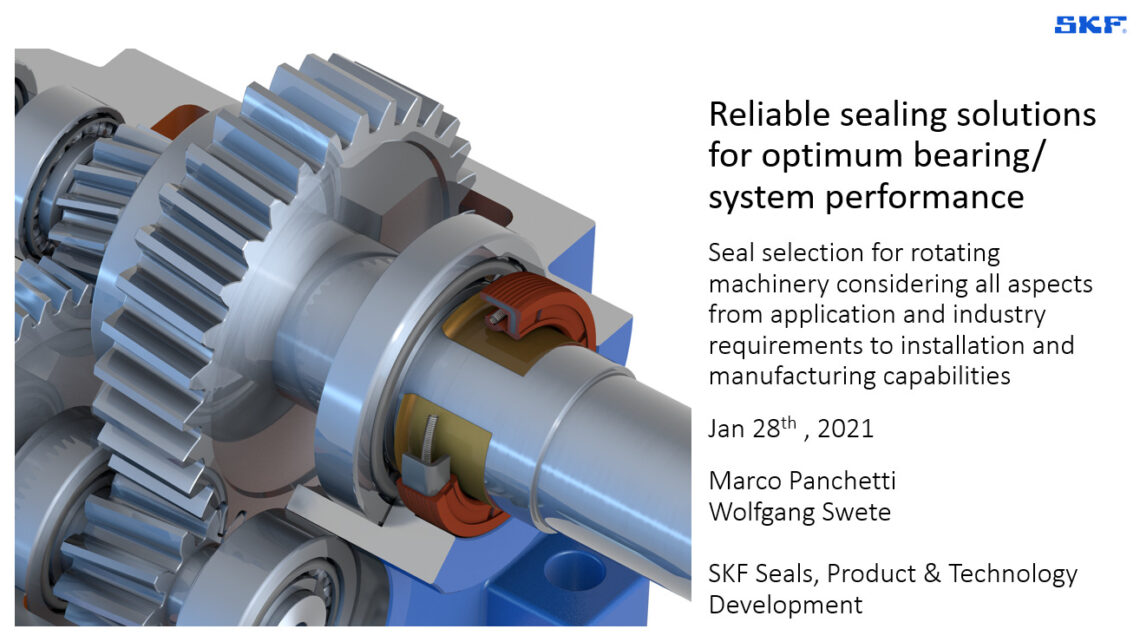

Reliable sealing solutions for optimum bearing/ system performance

“A bearing’s best friend is a properly selected seal!” This statement underlines the fact that around 50% of premature bearing failures are related to issues with the lubricants. Thus maintaining a high lubrication quality and keeping contamination out of the bearing system is crucial. A proper design of the whole rotating system, consisting of bearing, seal and lubricant, is the base for optimum Rotating Equipment Performance.

In this webinar you get to know more about principles and relevant factors that have an impact on the selection of rotary seals.Combined with the extensive industry related knowledge and experience in our multi-technology environment, we’ll give you a guideline to properly select appropriate rotary sealing solutions.