Uncovering the secret life of bearings

We've all heard of the butterfly effect - how small changes at an early stage can have tremendous effects later down the line. The way we see it, this type of reasoning also captures the fundamental value of bearing life calculations.

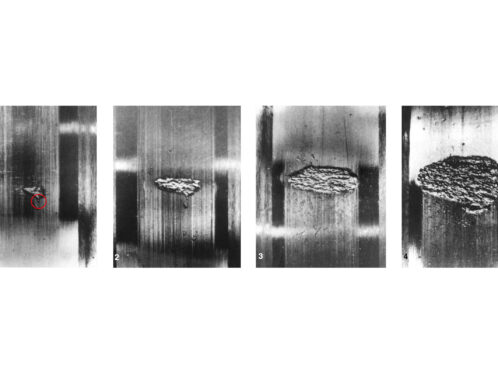

Bearing life, as it is called, is expressed as the number of revolutions – or the number of operating hours at a given speed – that a bearing is capable of enduring before the first sign of fatigue occurs on one of its rings or rolling elements. Under controlled laboratory conditions, however, seemingly identical bearings operating under identical conditions can have different endurance lives.

Over the years, we at SKF have developed several homegrown life models to help our customers select the right bearings for their applications. The first method to estimate the life of rolling-element bearings was developed already in 1924, then updated in 1947 and again in 1952 – by SKF engineers Arvid Palmgren and Gustaf Lundberg. Their research was published in the paper Dynamic Capacity of Rolling Bearings, and the major implication of their work was that bearing life is finite and influenced primarily by how the bearing is affected by loads. A bearing’s life could be extended if loads were kept under its design load, but if the bearing was overloaded, its life span would be shortened.

Later, this traditional life model became superseded by further technological developments, mainly owing to the vastly improved quality of the steel used in modern bearings. The mechanisms for how failures developed according to the 1924 model were simply not valid anymore; by the 1990s, bearings were found to give service lives up to 14 times longer than those predicted. The research went on, and, step-by-step, SKF engineers gradually uncovered new aspects and factors of what affects bearing life.

Today, there are three major life models in use: “Basic rating life”, “SKF rating life”, and the “Generalized Bearing Life Model”. Basically, the “Basic rating life” model – the one initially developed by Palmgren and Lundberg – is useful if you only have to consider load and speed; that is, when you know that the working conditions won’t have a particularly dramatic effect on the bearing. For modern high-quality bearings, however, service life depends not only on load, speed and bearing size, but on a variety of influencing factors like lubrication, degree of contamination, proper mounting and other environmental conditions. In such cases, the slightly more complex “SKF rating life” model is recommended.

In 2019, we relaunched GBLM. The updated model offers calculations for hybrid bearings, i.e. bearings with steel rings and ceramic rolling elements. The possibility to determine the working life of hybrid bearings more realistically has enormous implications for the industry with its insatiable appetite for downsizing and higher efficiency in field performance. Hybrid bearings are more expensive than steel bearings, but they are also lighter and harder, and can therefore run faster and hotter. They perform well in contaminated environments, even with poor lubrication. Until now it has been difficult for engineers to anticipate whether a hybrid bearing will outperform a steel bearing in a given application, or whether the possible performance benefits of hybrid bearings are worth the extra cost. Being able to predict the real-life performance of a hybrid bearing to such a high degree that GBLM offers can bring massive benefits in terms of efficiency, long-term cost savings and reduced environmental impact.

But what does all this have to do with chaos theory? Maybe not so much, maybe everything. We are, after all, talking about how shifting a few numbers in an equation could potentially change the face of an entire industry. Because bearing life information is essential. Not only for selecting bearings for an existing application, but even more so for designing new equipment. Realistic size calculations can help original equipment manufacturers optimize designs, making their machines smaller, lighter and faster. To us, the Generalized Bearing Life Model is nothing short of a game changer.

GBLM is a giant leap for bearing science and will enable better choices to be made when selecting bearings for a wide variety of applications.

Guillermo Morales-Espejel, Principal Scientist at SKF Research and Technology Development

With the Generalized Bearing Life Model, a new arena for innovation has been introduced – an open space where our customers can use the tools we provide to explore, improve or rethink the design and performance of their rotating equipment. A space where even the smallest adjustment can make a big difference to their industrial reality. How our customers choose to act in this arena is beyond our control. But we can at least guarantee a steady supply of equations.

In a way, the products and services we offer are just the tip of the iceberg. Below the surface, intense research and strong connections to the scientific community constitute the traditional SKF modus operandi. Below, deep in the academic chambers of tribology, all those bright ideas are constantly being born, rejected, reborn, nurtured, presented, refuted, recalculated and re-submitted. And it’s not just the life models. Everything connected to the improvement of rotating equipment is continuously being overturned, poked at, problematized and refined – in our everlasting quest to uncover the secret life of bearings.