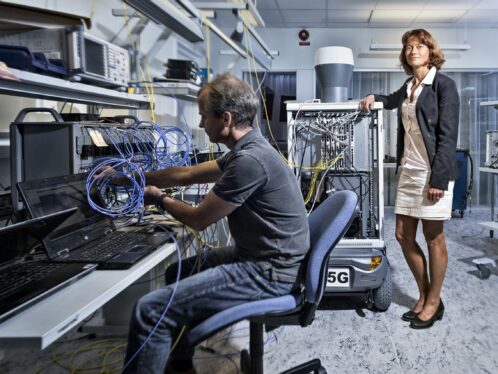

Rannveig Rist

Iceland’s first lady of aluminiumEven though Rannveig Rist is the only woman to occupy the top post in a large industrial corporation in Iceland, she finds questions about this distinction a bit tiresome. “I don’t do any of the things I do because I’m a woman,” she says. “My gender is not an issue and does not influence my work. I’m an engineer and a manager. That’s all.”

That succinct description covers a lot of ground.

The 36-year-old is chief executive officer of ISAL, a Swiss-owned aluminium smelter in Straumsvik, on the outskirts of Reykjavik, that annually produces US$270 million in aluminium. This accounts for more than 10 percent of Iceland’s exports.

Rist hasn’t exactly spent her life in corporate meeting rooms. Her first job was as assistant to her father, who spent his summers doing hydrological surveys in Iceland’s highlands. She recalls long rides over bad roads in uncomfortable vehicles, as well as long treks on foot. “We sometimes had to walk for an entire day carrying heavy equipment. Since then, no work has seemed difficult.”

This rigour prepared her for a string of tough jobs. Before starting university studies (she has a degree in mechanical engineering from the University of Iceland), Rist enrolled in Iceland’s Marine Engineering College, long a male domain. Rist was the only woman in the school at the time, and the only woman to graduate since her commencement in 1983. She later became the first woman in Iceland to complete training as a mechanic. “I was always determined to get a good education, and I was interested in engineering, engines and management. Studying mechanical engineering at a university was the obvious choice, but I figured that people in this business would never take a girl with a degree in mechanical engineering seriously. I would have to show that I had a solid background.”

Getting this background included becoming the first – and to date the only – female officer on an Icelandic fishing vessel. It was not easy for her to find a post. “They didn’t believe I was any good,” Rist recalls. “They were willing to hire me as a cook or a deckhand, but not as an officer. Seven trawlers left harbour with less qualified people in the engine room, until at last I was given a place on a trawler from the Westman Islands.”

After finishing her university studies in Iceland, Rist went to the United States to earn an MBA degree at the University of San Francisco in California. On her return in 1989 she went to work for ISAL as head of safety and environmental affairs. She moved on to head ISAL’s cast house and to act as the corporation’s spokesperson. In 1996, when CEO Christian Roth resigned his post, the management of Alusuisse-Lonza, ISAL’s Swiss-based owner, offered Rist the position. She accepted without hesitation. “Although I didn’t envisage this particular job, I always aimed to be in a position of influence,” says Rist. “This is not a question of coincidence or luck.”

Rist enjoys the “people” part of her job. At ISAL, 500 people work on shifts around the clock to produce 162,000 tonnes of aluminium a year. When Rist walks around the plant, she wears the same helmet and blue overalls as everyone else. She says she is a good reader of signals, whether they come from engines or people. “I like my job,” says Rist. “I find the leadership role in ISAL an exciting challenge. I am profoundly interested in what I’m doing, and I have the good fortune to work with very good people.”

Iceland has an export-driven economy, and ISAL is a leading exporter in a fiercely competitive global market. In Iceland, Rist says, “We are good at many things, especially educating people. Our basic compulsory education is good, and our higher education is good as well. Many Icelanders get their postgraduate education abroad, which creates a unique business environment. People return to Iceland with an education from different countries and cultures. This makes us strong in global competition. But what is lacking is education for the worker on the factory floor. We haven’t capitalised on our human resources as much as we could.”

In addition, Rist says Icelanders tend to be ill-prepared and too often make last-minute decisions. “For example,” she says, “Icelanders like foreign investment, but we haven’t prepared ourselves for it. We do not know what kind of investment we want or how we want to educate investors. We usually decide upon these things when the deal is about to be struck. I cooperate with Switzerland a lot, and I try to learn from the Swiss way of long-term thinking.”

In Rist’s view, the aluminium industry in Iceland has a bright future. “We need to exert ourselves if we are to produce metals in a country with such a high living standard,” she says, noting that other countries can produce aluminium at a much lower cost. “But,” she continues, “Iceland has low-priced, clean hydropower, good harbours and skilled labour.” These strengths are proving an attraction to foreign investment. A U.S. aluminium producer, Columbia Enterprises, plans to open a 60,000-tonne smelter in 1998, and the Icelandic government is negotiating with at least two other potential investors in the aluminium sector. Rist also believes in the competitiveness of ISAL in the industry.

A few years ago the plant was over-staffed and not particularly environmentally friendly, she says. A programme of increased automation and restructuring in the production process is now yielding good results. Production has been increased, and fewer employees are needed to produce the same quantity of aluminium. “I believe ISAL’s future is rather bright,” Rist says. “The plant is effectively sized, which increases its life expectancy. It is large enough to be competitive. But aluminium is not just aluminium. We must progressively make an effort to make specialised products and offer shorter delivery periods.”

Like her predecessor, Christian Roth, Rist is preoccupied by environmental concerns. Large industrial plants are always a cause of controversy, especially in a country like Iceland, which prides itself on its unspoiled nature. But Rist is convinced it is possible to reconcile industry and environment, particularly in heavy industry, which is concentrated in small areas.

Large industrial corporations are so few in Iceland that each can make a difference when it comes to environmental-protection measures. For example, from 1990 to 1995 ISAL’s reduction of greenhouse gas emissions, especially chlorofluorocarbons (CFCs), from the plant more than offset increased emissions from the rest of industry in Iceland.

“Environmental consciousness is of great importance in this business,” says Rist. “In the past, environmental issues were not given enough attention here, but this is changing. We will make an effort to stay ahead when it comes to environmental standards. Aluminium production contributes to a better environment, since few metals are easier to recycle. Aluminium has been called the green metal, and that is one reason aluminium production has a great future.”

Ólafur Stephensen

a journalist on the staff of Iceland daily Morgunbladid