A record-setting partnership

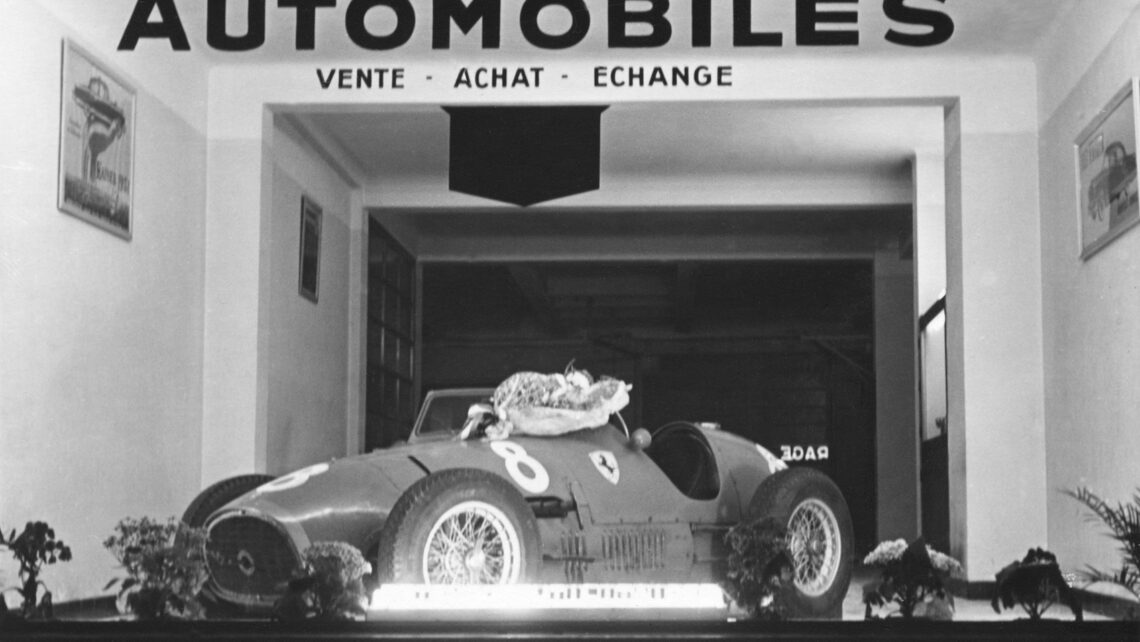

Ferrari and SKF have collaborated for the 70 years the automaker has been in business, a partnership resulting in the longest uninterrupted technical cooperation in Formula 1 history.

The basic idea, the finishing of a new sports car, is always the work of a team. It is a compendium. A collaborative effort.

Enzo Ferrari

He once said, “The basic idea, the finishing of a new sports car, is always the work of a team. It is a compendium. A collaborative effort.”

SKF, as bearing manufacturer and leading technology provider in the field, has been working with Ferrari since 1947. As such, it resulted in the longest uninterrupted technical cooperation in Formula 1 history. Formula 1 specifications have changed dramatically over the years, the technology has evolved along with new composite materials, and the individuals working together from the two companies have changed many times over. Yet this partnership remains as solid as ever.

Andrea Candelpergher, gearbox design leader at Scuderia Ferrari’s design department, lists four reasons why: accessibility, speed, compatibility and experience.

Accessibility means that SKF is there when needed. “When we have had emergencies or when speed of response has been critical, SKF has always responded quickly, supplying us with components or expertise or whatever was needed,” he says. Andrea Rifici, SKF application engineer for Formula 1, Italy, reinforces that perspective. “The world of F1 never stops and neither do we,” he says. “We are available at any time, including weekends.”

Speed is obviously important in F1 racing, as performance on the racetrack is measured in milliseconds. For a supplier, speed means not only a fast initial response but also quick manufacturing turnaround. SKF can produce a first prototype of a new bearing in 12 weeks to meet Ferrari’s needs.

Compatibility acknowledges that the Ferrari team and its SKF counterparts are on the same wavelength. Candelpergher points out that the SKF engineers who work with his group “think like we do”. “They are all in sync with Ferrari’s vision of F1 racing,” he says.

The basic idea, the finishing of a new sports car, is always the work of a team. It is a compendium. A collaborative effort.

Enzo Ferrari

Working with Ferrari is a huge responsibility for the three SKF engineers assigned to this project, Rifici says. “We are considered a part of the Ferrari team,” he explains. “We share the same ideals and objectives and desire to win. We trust each other.” They enjoy first-line communication with their Scuderia counterparts and have the freedom to develop special products for Ferrari. Emphasis is on weight reduction, lowering frictional moments and use of the most advanced technologies available.

Experience is shorthand for SKF’s vast knowledge of bearings in myriad applications. That accumulated wisdom serves the team well because of the speed and complexity of F1 racing. Just one Ferrari incorporates 150 different kinds of SKF components. “The total number is larger,” Rifici says. Moreover, every year a number of Ferrari’s bearings are modified or redesigned to reflect changing requirements, new regulations, new materials, new strategies and issues encountered while racing. Ferrari analyses these problems, then sends the bearings to SKF for further analysis and suggestions for improvement. The cycle of develop-test-race-feedback-modify is a continuous loop.

Because the world of F1 racing is secretive and highly competitive, specific examples of improvement are rarely revealed. But Rifici recalls that when the material of a set of bearings was changed from standard industrial steel to a special steel alloy, racetrack performance improved immediately.

In addition to yearly Formula 1 racing regulation changes, there are significant changes every four or five years. Changes for 2017 include modifications in aerodynamics and a shift to bigger tyres. Wheel bearings are affected because they must support higher speed, heavier weight and increased temperature with the same or better performance and reliability. Ferrari looks to SKF for bearings, and wheel bearings in particular, that maximize performance with minimal dimensions and lowest weight.

“We meet with SKF weekly to discuss problems, developments and design issues,” Candelpergher says. “It helps that we have always enjoyed a personal relationship with them.” Echoing Enzo Ferrari’s description of teamwork decades earlier, he adds, “The human dimension may help explain why our collaboration has lasted so long.”