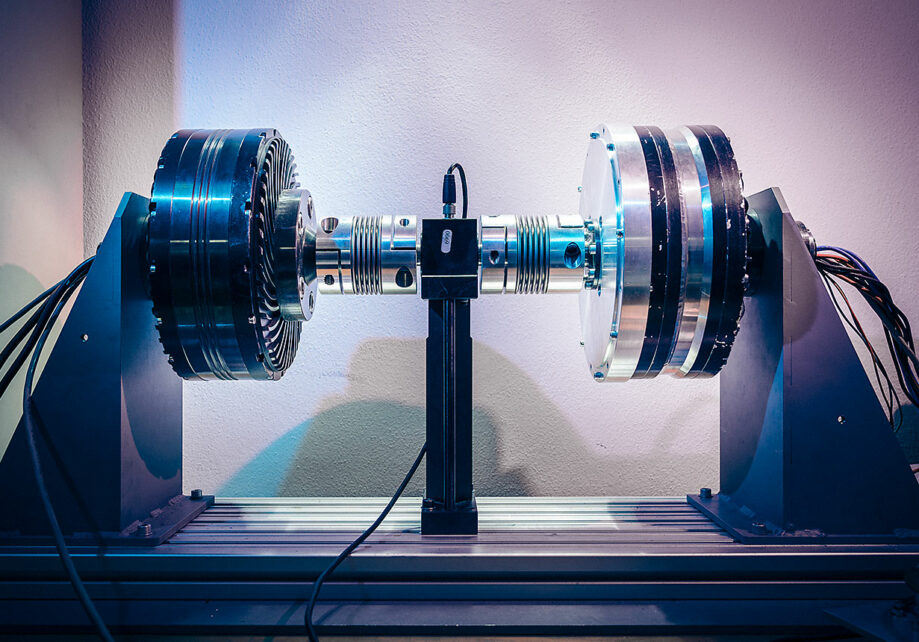

GEM in-wheel electric motors on the rise

In-wheel electric motors have been around since the late 1800s, but they have come into their own recently with advancements in electric motor technology. Slovenian company GEM is ready to reap success in a growing market.

In the late 1990s, as a postgraduate student in Ljubljana, Slovenia, Simon Mandelj was fascinated by non-linear dynamics. His academic and post-doctoral research in this field led him to design an in-wheel motor that was competitively superior to those available commercially.

In 2010, he founded GEM Motors, focusing on innovative in-wheel electric propulsion for the light electric vehicle (LEV) market, which was growing rapidly. He chose the name GEM Motors with care. The “G” comes from the Slovenian word for “moving”: gibanje. “E” stands for electricity and “M” for magnetics. Also, explains the founder, “A gem is a precious stone that represents beauty, simplicity and perfection, and our solution is likewise – technically beautiful, simple and perfectly suited to its purpose.”

Potential customers for GEM in-wheel electric motors

As of late 2017, GEM had 15 clients testing its GEM wheel drives, and a number of “very interested” potential customers based in Switzerland, France, Sweden, Germany and Italy, and a few from South America, South-East Asia and the United States. “We are currently focusing on Europe since that is our home market,” says Mandelj. This, he says, will be followed by an expansion that will concentrate first on the potentially huge US market and then roll out globally.

The market is huge and our solution is very good.

Simon Mandelj

CEO and founder

GEM is going into production in 2018 with two of its product offerings – GEM in-wheel drives with 4 kW and 6 kW of nominal power. It estimates production of 100,000 units within five years because, says Mandelj, “the market is huge and our solution is very good.”

The company’s intended customers are the manufacturers of small two-seater cars for urban mobility and personal transport, golf carts, postal delivery and similar small commercial vehicles, motor scooters, motorbikes and small tractors for lawn mowing.

The market is growing exponentially

Future trends are moving in favour of electric mobility, observes Aleš Čavs, SKF key account manager, Slovenia. “GEM is firmly focused in this direction and we are eager to encourage their development.”

The market, in fact, is growing exponentially; by 2040, more electric vehicles will be sold than gas-powered cars, according to a 2017 report by Morgan Stanley. The demand is for simple, efficient, smart, compact, cost-effective, fully integrated solutions, and GEM has positioned itself to meet these requirements.

Another growing market trend, driverless cars, also works in GEM’s favour. In-wheel motors are a plus for driverless vehicles because they can be controlled individually by computer, whether two, three or four wheels.

But that’s not enough, says Mandelj. A good solution is one that end customers will enjoy when driving their vehicles. He promises that driving with GEMs will be a pleasure – you might say a “gem” of a ride.

A unique brake solution

When GEM Motors was asked to add a parking brake solution to the in-wheel electric motor they were developing for a new postal vehicle, they realized that there was no readily available solution on the market.

Dr Andrej Pukšič, senior research engineer at GEM Motors, recounts the challenges. “The brake is outside rather than inside the motor,” he says, “so it had to be a robust unit, resistant to water, dust, debris, mud and shock. We researched solutions in the market and found only inappropriate automotive options. They were closed systems, customized for specific automotive clients, and we couldn’t get the information we needed.”

So GEM turned to SKF, which has experience in this field; SKF has been selling electronic parking brakes (EPBs) for tractors since 2009. SKF’s solution was the best of several options that GEM examined. The Slovenian company started with an SKF EPB sample, and then the two companies worked together to adapt it for light electric vehicles. SKF’s customized EPB and engineering support capabilities have led to a robust and reliable vehicle solution.

The electronic brake on the new postal vehicle is connected to the in-wheel motor by cable and callipers, with two options for operation: the driver activates the parking brake manually by pressing a button, or the brake is applied automatically (when sensors in the wheel detect that the wheels have stopped turning, they automatically activate the parking brake).

“We wanted high-quality components, and SKF is technologically advanced and known for its quality,” says Mandelj.