Simulation software saves the day

SimPro Quick, SKF’s simulation software, came to the rescue when engineers at Italian-headquartered ESPE faced a seemingly insoluble alternator problem.

Simone Mariga, an ESPE managing partner, and Sergio Toniato, of ESPE’s technical department, suspected that the alternator’s bearings were involved in the breakdowns, but they couldn’t be sure because the supplier was no longer around to provide information.

The SKF software was intuitive to use and the result was extremely refined.

Sergio Toniato, ESPE technical department

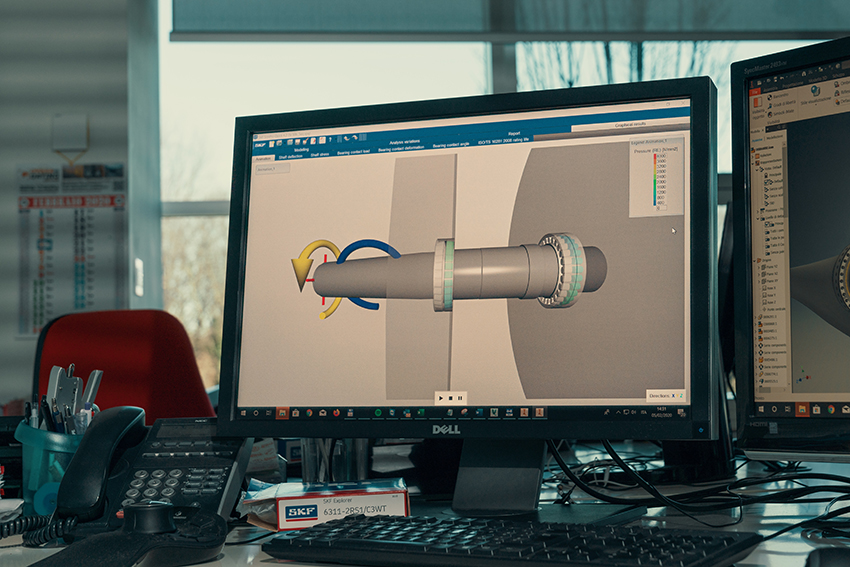

The solution came in the form of SimPro Quick, SKF’s simulation software. The software, introduced in 2016, evaluates the bearing arrangement designs and their field performance based on relevant application requirements and operating conditions. Toniato had used simulation software from other suppliers in the past but had found the software to be not much more than automated product catalogues. By comparison, SimPro Quick has multiple modelling capabilities and takes into account bearing loads, shaft deflection, loaded zones, contact stresses, friction, frequencies, bearing life, grease life and relubrication intervals.

Another advantage of SimPro Quick is that it communicates easily with SimPro Expert, SKF’s internal software for bearing analysis, so the ESPE and SKF engineers were able to speak the same language when they exchanged information, and they could do so quickly and easily.

SKF used data from SimPro Quick to do a root-cause failure analysis of the bearings vis-à-vis the design of the generators. The analysis helped ESPE develop a viable solution with appropriate bearings.

Mariga points out that the company uses SimPro Quick on a daily basis for its growing wind turbine business. But that is only the beginning of the software’s potential. Fabio Meneghetti, purchasing manager and a managing partner of ESPE, comments, “We have seen a reduction in planning time because the software is a big help to the technical department. Purchasing decisions for bearings and lubricants are more detailed and precise, and we are saving time in supply inventory. We feel the impact company-wide.”

What began as a problem to be solved has become a market opportunity for future growth.

ESPE

The name began as an acronym for “Elettromeccanica Strumentazione Pneumatica Elettronica” (Electromechanical Electronic Pneumatic Instrumentation). “It doesn’t make any more sense in Italian than it does in English,” admits Fabio Meneghetti, son of the founder and a current partner in the firm. “But in 1974, acronyms were in vogue.”

Eight years later, in 1982, the company constructed its first hydroelectric turbine, based on the potential the management saw in renewable energy over the long term. Between 1990 and 2010, ESPE established a number of commercial offices in Romania, eventually leading to the construction or re-engineering of five hydroelectric plants in that country.

As the company continued to expand in Italy and abroad, renewable energy became its dominant focus. In 2001 ESPE completed its first photovoltaic installation, and the company determined that the future lay in that direction. By 2011 it had developed proprietary technologies for the construction of mini wind turbines and wood biomass cogenerators. “Today we can state with assurance that the vision of ESPE’s founders was far-sighted,” reflects Meneghetti.

Now photovoltaic installations, both for companies and for large solar parks, are ESPE’s fastest-growing area of business. Mini wind turbines and biomass cogenerators are attractive niche sectors with growth potential. Hydroelectric plants are the fourth (but decreasingly important) area of business.

“Competition today is fierce,” Meneghetti observes. “A successful business must invest in technology, training and marketing while treating its employees, customers and suppliers with humanity.”