The right bearing stops downtime in the automotive industry

One German vehicle manufacturer increased its service life from some three months to more than 36 months with an SKF-tailored spherical roller bearing solution.

The rate of technological change in manufacturing is accelerating. Machinery is advancing and output is increasing. As factories evolve, however, small details are often overlooked – particularly when it comes to bearings.

The automotive sector is a case in point. During the 1980s, a typical car weighed a little more than 1,000 kilograms. Today, it’s not uncommon to see vehicles that weigh double that. Meanwhile, improvements in manufacturing techniques mean factories are producing more cars than ever in a fraction of the time.

Weak conveyors often a problem

Changes in manufacturing techniques and increased production rates can place stress on the existing environment, particularly the conveyors and the bearings that support them. Increasingly, SKF engineers are visiting factories suffering from downtime because conveyors have been unable to support larger loads or increased production. The problem, says Corinna Ulherr, industrial sales, application engineer at SKF, can often be narrowed to bearings that haven’t been upgraded in line with factory floor changes or were selected incorrectly at the outset.

“Most of the time a manufacturer might have an existing line, for example, and they want a higher output or have heavier cars, and they just don’t think about the bearings in the conveyors,” Ulherr says. “Often insert bearings are the problem, because they can’t accommodate the new production rate or the new load situation.”

Weak conveyors often a problem

Changes in manufacturing techniques and increased production rates can place stress on the existing environment, particularly the conveyors and the bearings that support them. Increasingly, SKF engineers are visiting factories suffering from downtime because conveyors have been unable to support larger loads or increased production. The problem, says Corinna Ulherr, industrial sales, application engineer at SKF, can often be narrowed to bearings that haven’t been upgraded in line with factory floor changes or were selected incorrectly at the outset.

“Most of the time a manufacturer might have an existing line, for example, and they want a higher output or have heavier cars, and they just don’t think about the bearings in the conveyors,” Ulherr says. “Often insert bearings are the problem, because they can’t accommodate the new production rate or the new load situation.”

Misuse of insert bearings a common mistake

Problems deriving from the misuse of insert bearings appear across many sectors, particularly those that use multiple conveyors in challenging operating conditions. In 2018, Ulherr visited a vehicle manufacturer in Germany that was experiencing bearing failures every three to six months.

Often insert bearings are the problem, because they can’t accommodate the new production rate or the new load situation.

Corinna Ulherr, industrial sales, application engineer at SKF.

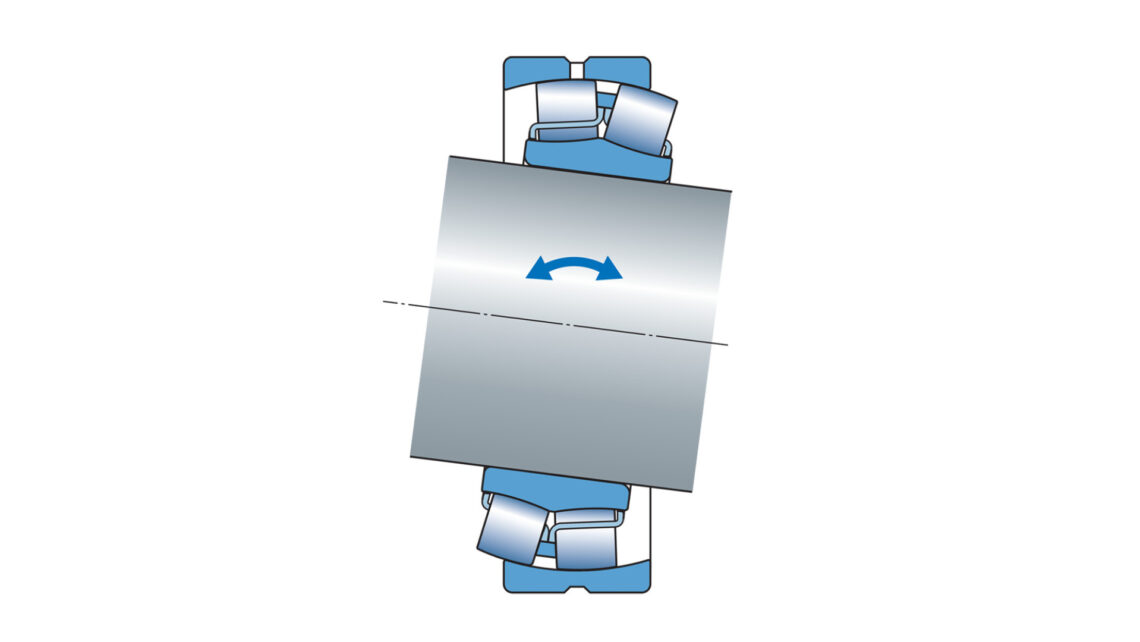

The equipment in question was part of a five-metre-wide conveyor used to carry workers while they worked on the cars. The width of the conveyor meant that a temperature increase of a few degrees resulted in a thermal elongation of the shafts. Insert bearings are always locating bearings, so they cannot accommodate shaft elongation.

The elongation, together with a slight misalignment of the belt, induced axial forces that further increased the load on the bearings. Radial forces from the heavy drum and pretension of the belt were also higher than the bearings were designed to endure. To make matters worse, the bearings were insufficiently lubricated and failed as a result.

“Insert bearings are often used because they are simple and quick to mount, but it’s easy to forget that they are just locating bearings,” Ulherr says. “It can be a costly mistake, because when they fail, often you can’t change them without halting production.”

That was the case at the German vehicle manufacturer. Production halted while the bearings were changed. Workers who were temporarily without the conveyor had to walk alongside the cars to continue their work. Production fell 10 percent.

A solution with higher carrying capacity

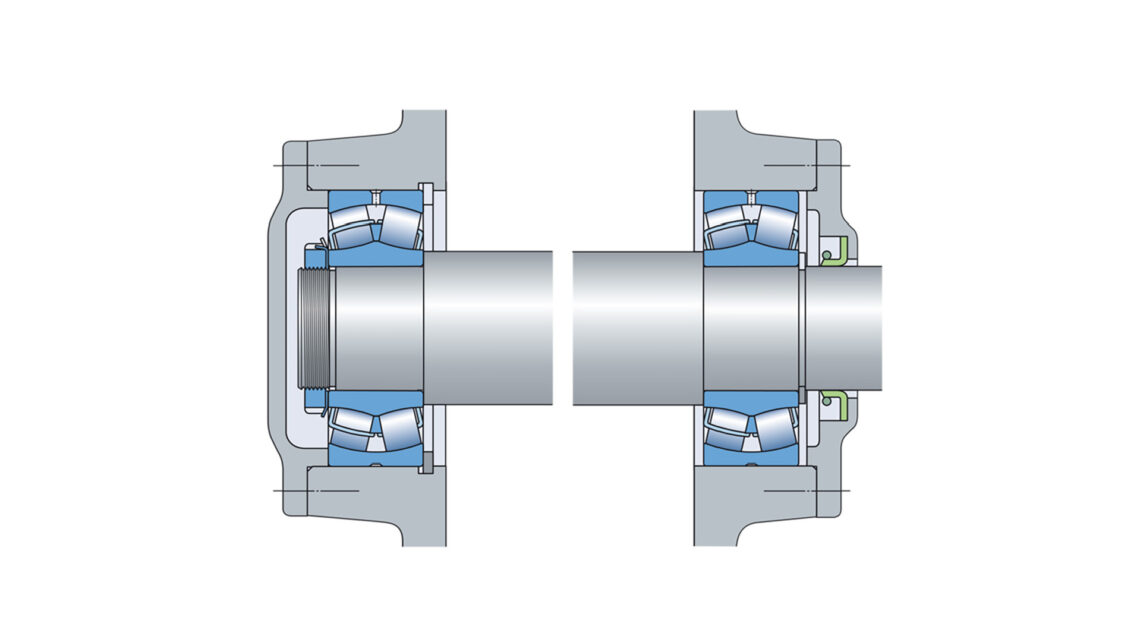

Ulherr’s solution included installing SKF sealed spherical roller bearings inside specially designed housings. “The roller bearings have a much higher carrying capacity than the small insert bearings,” she says, “and they have an added advantage in that they can also accommodate a misalignment of the shaft, which is common in these applications. The non-locating bearing can move axially in the housing seat and therefore easily accommodate the shaft elongation. Meanwhile, the locating bearing carries the axial loads.”

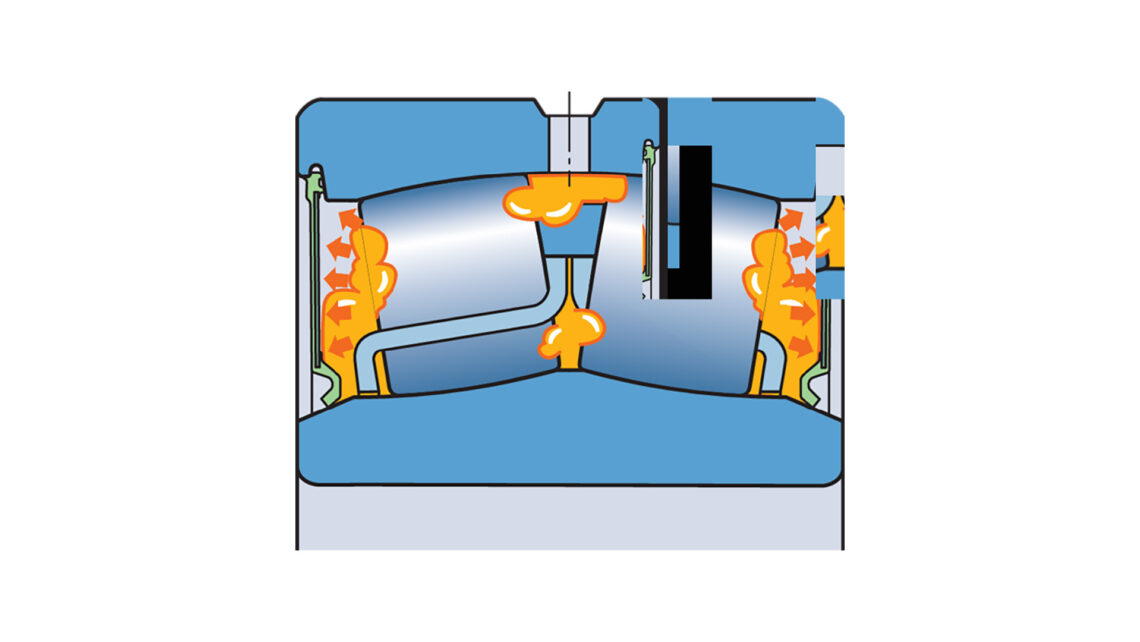

The right lubrication was also a vital piece of the puzzle. Conveyors moving at low speeds require grease with a high oil viscosity. Lubricating the bearings with SKF Grease LGEV2, a high-viscosity, mineral-oil-based grease containing molybdenum disulphide and graphite, proved optimal for lubricating the bearings at the low speeds used by the workers while assembling the cars. Grease with mineral particles such as graphite is particularly important for applications that require production to stop and start regularly or to move in different directions.

Significant increase in service life

Ulherr’s measures increased service life from some three months to more than 36 months and significantly lowered the risk of failure.

“Although this was a specific situation, I have a lot of cases like this,” Ulherr says. “We are often facing problems with insert bearings because the customers are just not aware that they cannot accommodate a heavy load or that they are only locating bearings.”

Ulherr’s message to factory operators is clear: as soon as you redesign machinery or you have a load or speed change, you must revisit your bearing selection. Although the German vehicle manufacturer opted for a tailored system, Ulherr says she always seeks to use standard components so that it’s easier for customers to replace them when they need to. That’s not always possible, however, so choosing correctly during the design or redesign phase can save a lot of downtime in the long run.

“My goal is more to make the customers aware that when they set up a new line or a new machine, they should think about the bearings they have used and not just reuse bearings because they worked before,” Ulherr says. “We can always customize solutions, but it’s always better for the customer if they consider all the bearings in use right from the start.”

SKF Bearing Rating Life

The fatigue life of an individual bearing is the number of revolutions (or the number of operating hours at a constant speed) that the bearing operates before the first sign of metal fatigue (rolling contact fatigue or spalling) occurs on one of its rings or rolling elements. Laboratory tests and practical experience both show considerable variation in the fatigue life of identical bearings operating under identical conditions.

When you want to avoid fatigue failures of the bearing before your application reaches its desired lifetime, you can use a statistical approach to determine the bearing size. The rating life L10 is the fatigue life that can be expected to be attained or exceeded by 90 percent of a sufficiently large group of identical bearings operating under identical conditions.

The rating life L10 is a proven and effective tool that can be used to determine a bearing size that is adequate to avoid fatigue failures. Compare the calculated rating life with the service-life expectations of the bearing application. You can use your experience from previous selections, if available, or apply the guidelines on the SKF website.